Method for extracting lithium salt from high magnesium-lithium ratio salt lake brine

A technology of salt lake brine and high magnesium-lithium ratio, applied in the direction of lithium carbonate;/acid carbonate, process efficiency improvement, etc., can solve the problem of large water-soluble loss of organic phase, difficult digestion of by-product hydrochloric acid, and complicated process flow and other issues, to achieve the effects of reducing energy consumption, improving purity, and high process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] Lithium-containing original salt lake brine is exposed to the sun in a solar salt field to obtain lithium-rich brine saturated with magnesium chloride. The brine composition (g / l): Li + 1.85, Na + 0.82,K + 0.65, Mg 2+ 106,B 2 o 3 3.64, SO 4 2- 32.63; the lithium-rich brine is spray-dried, the feed temperature of the spray-drying is room temperature, the air-in temperature of the spray-drying is 360°C, and the air-out temperature is 150°C, and a dry dehydrated solid product containing lithium chloride is produced; Dry and dehydrate the solid product at 150~300°C for 1~60min with ammonia gas flow to generate an ammonified solid product containing magnesium chloride ammonium compound and lithium chloride; use 50~100% ammonia saturated ethanol for the ammoniated solid product Solution 5-stage countercurrent extraction, extraction liquid-solid ratio 5:1, extraction time 80min, extraction temperature 20~30°C; after extraction, the slurry was centrifuged to obtain lithiu...

specific Embodiment 2

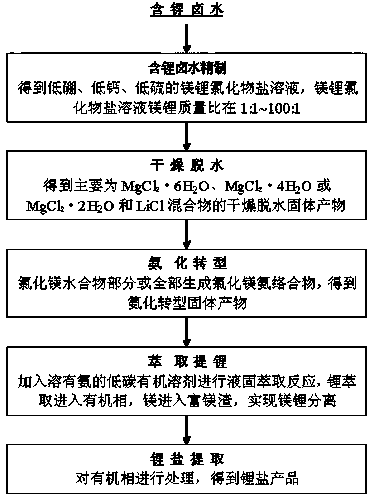

[0029] Such as figure 1 As shown, the lithium-rich brine saturated with magnesium chloride is evaporated and concentrated—acidified to extract boron—extracted to extract boron—removed from sulfate to obtain refined brine, and the composition of refined brine (g / l): Li + 9.88, Na + 0.35,K + 0.24, Mg 2+ 106,B 2 o 3 0.12, SO 4 2- 0.46; the refined brine is spray-dried, the feed temperature of the spray drying is 120°C, the air inlet temperature of the spray drying is 400°C, and the air outlet temperature is 180°C, and a dry dehydrated solid product containing lithium chloride is produced; the Dry and dehydrate the solid product at 150~300°C through ammonia gas flow for 1~60min to generate an ammoniated solid product containing magnesium chloride ammonium compound and lithium chloride; use 80~100% ammonia saturated ethanol for the ammoniated solid product 5-stage countercurrent extraction of the solution, the extraction liquid-solid ratio is 10:1, the extraction time is 120...

specific Embodiment 3

[0031] Lithium-rich brine saturated with magnesium chloride is concentrated by evaporation—acidification to extract boron—extraction to extract boron—removal of sulfate to obtain refined brine. The composition of refined brine (g / l): Li + 9.88, Na + 0.35,K + 0.24, Mg 2+ 106,B2 o 3 0.12, SO 4 2- 0.46; the refined brine is spray-dried, the feed temperature of the spray drying is 120°C, the air inlet temperature of the spray drying is 400°C, and the air outlet temperature is 180°C, and a dry dehydrated solid product containing lithium chloride is produced; the Dry and dehydrate the solid product at 150~300°C through ammonia gas flow for 1~60min to generate an ammoniated solid product containing magnesium chloride ammonium compound and lithium chloride; use 80~100% ammonia saturated ethanol for the ammoniated solid product 5-stage countercurrent extraction of the solution, the extraction liquid-solid ratio is 10:1, the extraction time is 120min, and the extraction temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com