Semi-aqueous cleaning agent composition as well as preparation method and optical cleaning application thereof

A cleaning composition, water-based technology, applied in the direction of detergent composition, cleaning method and utensils, organic cleaning composition, etc., can solve the problems of limiting the pass rate of resin lens coating, damaging the health of operators, increasing labor costs, etc., to achieve Improve the performance of removing putty and solid impurities, improve the cleanliness, and reduce the use loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

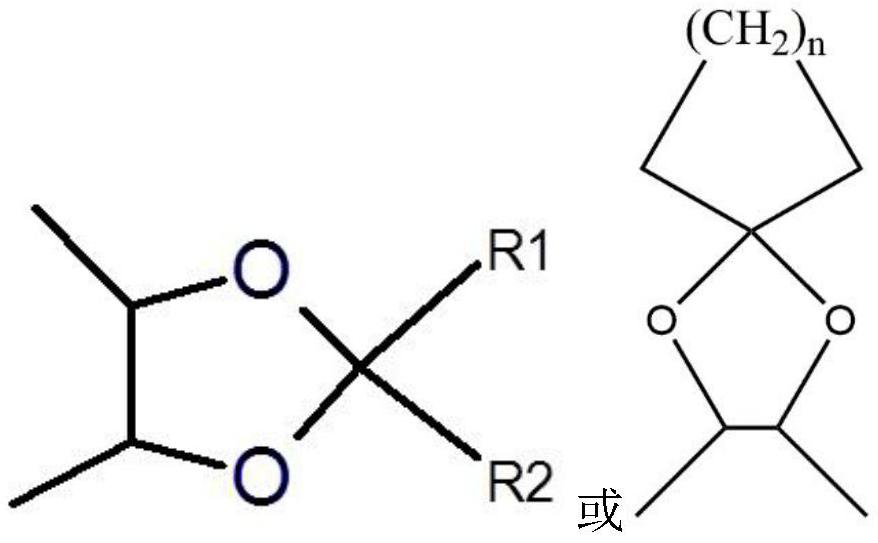

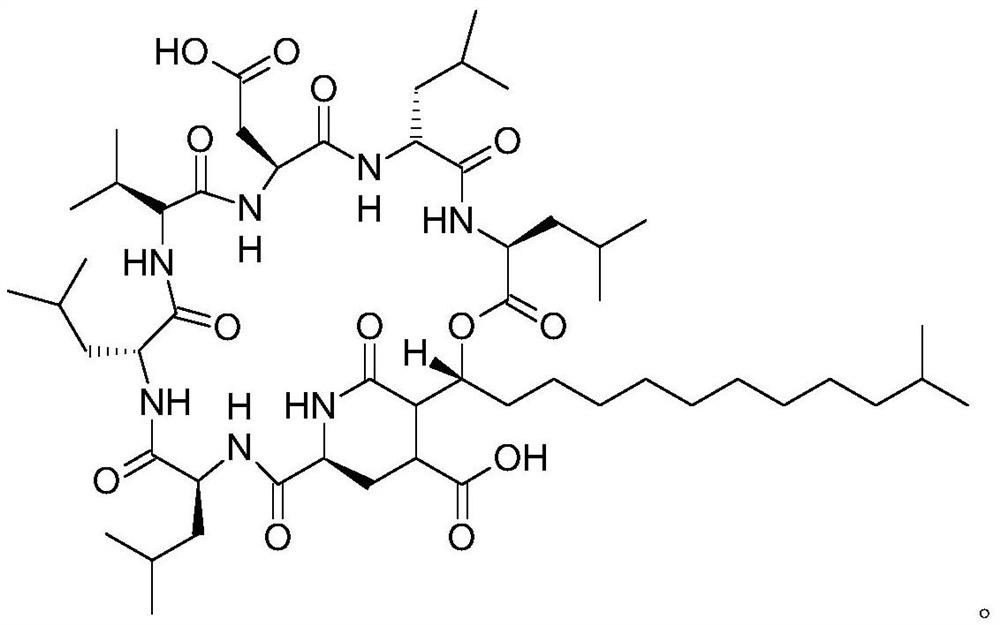

Embodiment 1

[0058] Weigh each raw material according to the following mass fraction: 1% surfactin, 2% sophorolipid, 1% sodium hydroxide, 5% sodium carbonate, 3% sodium metasilicate, 2,3-butanediol furfural solvent 5%, N,N-diethylhydroxylamine 2%, and the balance is deionized water. The sophorolipid is a mixture obtained by the fermentation of Candida, which contains 50 wt% of acid type sophorolipid and 40 wt% of lactone type sophorolipid.

[0059] First, according to the mass content of each substance, add water into the reaction kettle, heat to 40°C, add sodium hydroxide, sodium carbonate, and sodium metasilicate in turn under stirring conditions, stir and dissolve for 2 hours, and then add surfactant peptides surfactin, Sophorolipids and N,N-diethylhydroxylamine were stirred and dissolved at 40°C for 1 hour, and finally 2,3-butanediol furfural solvent was added, and stirred and dissolved for 0.5 hours to obtain an environmentally friendly semi-aqueous cleaning combination thing.

[00...

Embodiment 2

[0066] The raw materials were weighed according to the following mass fractions: 3% surfactant peptide surfactin, 2% sophorolipid, 5% sodium hydroxide, 1% sodium carbonate, 8% sodium metasilicate, 2,3-butanediol butyral 20% solvent, 10% N,N-diethylhydroxylamine, and deionized water as the rest. The sophorolipid is a mixture obtained by the fermentation of Candida yeast, which contains 50% wt of acid type sophorolipid and 40% wt of lactone type sophorolipid.

[0067] First, according to the mass content of each substance, add water into the reaction kettle, heat to 50°C, add sodium hydroxide, sodium carbonate, and sodium metasilicate in sequence under stirring conditions, stir and dissolve for 2 hours, and then add surfactant peptides surfactin, Sophorolipid and N,N diethylhydroxylamine were stirred and dissolved at 50°C for 1 hour, and finally 2,3-butanediol butanediol solvent was added, and stirred and dissolved for 0.5 hours to obtain an environmentally friendly semi-aqueous...

Embodiment 3

[0074] The raw materials were weighed according to the following mass fractions: 2% surfactant peptide surfactin, 10% sophorolipid, 4% sodium hydroxide, 4% sodium carbonate, 3% sodium metasilicate, 2,3-butanediol benzal 10%, N,N-diethylhydroxylamine 15%, and the balance is deionized water. The sophorolipid is a mixture obtained by the fermentation of Candida, which contains 50 wt% of acid type sophorolipid and 40 wt% of lactone type sophorolipid.

[0075] First, according to the mass content of each substance, add water into the reaction kettle, heat to 30°C, add sodium hydroxide, sodium carbonate, and sodium metasilicate in turn under stirring conditions, stir and dissolve for 1 hour, and then add surfactant peptides surfactin, Sophorolipids and N,N-diethylhydroxylamine were stirred and dissolved at 30°C for 1.5 hours, and finally 2,3-butanediol benzal was added into the solvent, and stirred and dissolved for 1 hour, which can be used for environmental-friendly semi-aqueous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com