Zero-emission oxidation device and method for producing hydrogen peroxide by anthraquinone method

A hydrogen peroxide and oxidation device technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, separation methods, etc., can solve the problem of inability to reduce gas phase composition, etc. problems, to achieve the effect of eliminating fugitive emissions, ensuring safety, and improving process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Hydrogen peroxide was prepared using an oxidation apparatus for producing hydrogen peroxide by the anthraquinone method as follows.

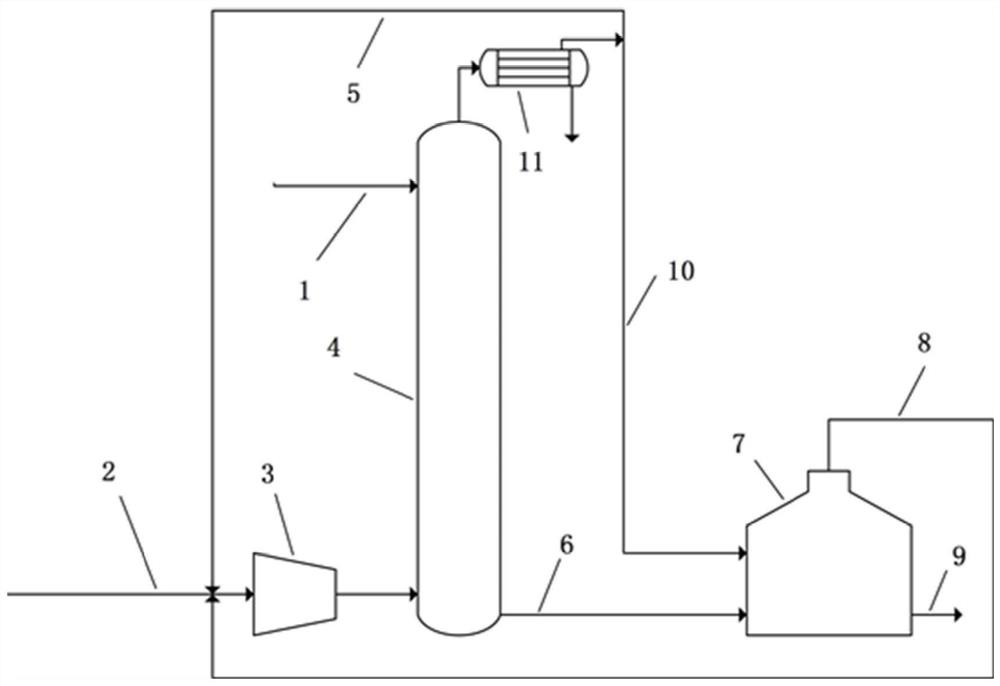

[0059] Such as figure 1 As shown, the oxidation device includes an oxidation tower 4 and an oxidation liquid receiving tank 7; wherein, the oxidation tower 4 supplies oxygen-enriched gas through a gas supply unit 3 (air compressor), and introduces a hydrogenation liquid through a hydrogenation liquid inlet 1 for The hydrogenated liquid and the oxygen-enriched gas undergo an oxidation reaction to obtain an oxidized liquid containing hydrogen peroxide, and the oxidized liquid is exported through the oxidized liquid outlet pipe 6 and stored in the oxidized liquid receiving tank 7;

[0060] The gas supply unit 3 is arranged at the top of the oxidation tower 4, and the hydrogenated liquid inlet 1 is arranged at the bottom of the oxidation tower 4;

[0061] The tail gas outlet of the oxidizing liquid receiving tank 7 is connected to the oxygen...

Embodiment 2

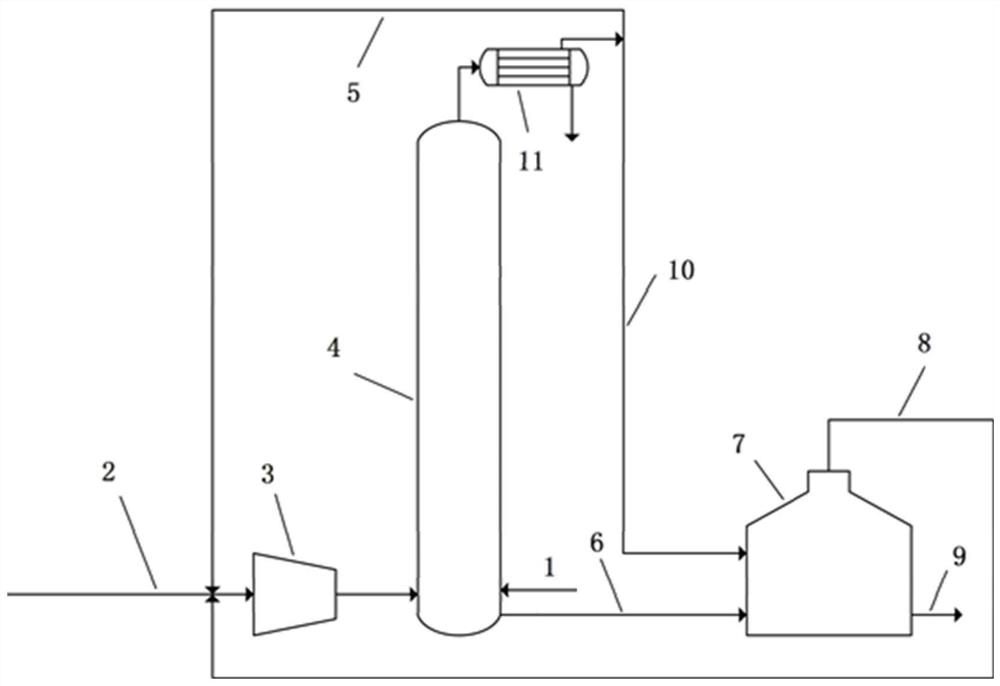

[0067] Use the method for embodiment 1 to prepare hydrogen peroxide, the only difference is that use figure 2 The oxidation device shown, the oxidation device with the figure 1 The difference of the shown oxidation device is: the gas supply unit 3 and the hydrogenated liquid inlet 1 are all arranged at the bottom of the oxidation tower 4; during the reaction, the hydrogenated liquid and the oxygen-enriched gas flow from bottom to bottom in the tower. and upward flow, so that the hydrogenated liquid and the oxygen-enriched gas are oxidized in parallel to obtain the oxidized liquid containing hydrogen peroxide.

[0068] Prepare hydrogen peroxide by using the oxidation device and method for producing hydrogen peroxide by the anthraquinone method of the above-mentioned embodiment 1-2, compared with the existing oxidation device and method that do not reuse the tail gas of the oxidizing solution receiving tank, it can be used without In addition, in the case of purchasing nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com