Treatment method of sulfur-containing slurry

A treatment method and slurry technology, applied in sludge treatment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of large demand for chemicals, secondary pollution, and high cost, and improve process economy. High performance, high removal rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

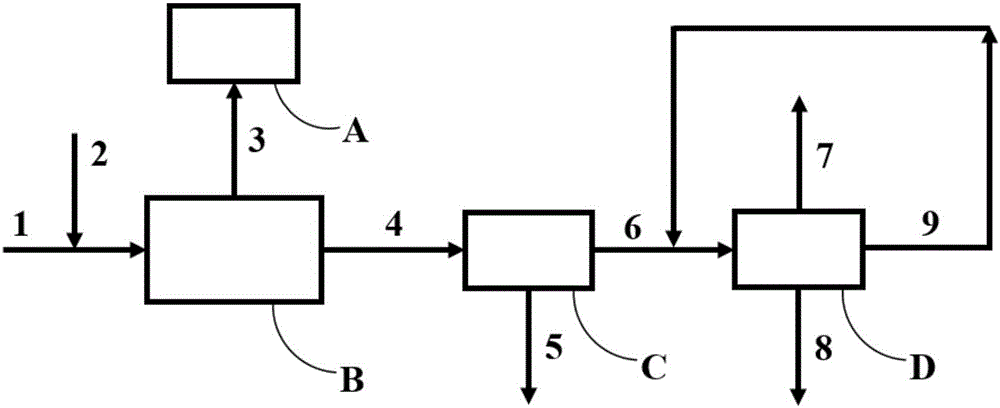

[0042] A method for treating sulfur-containing mud, the steps are as follows:

[0043] (1) 50g of sulfur-containing mud produced by adopting pesticide intermediates (wherein the mass fraction of each component is about: water 46%; sodium chloride 27%; sodium thiosulfate 7%; sulfur 13%; organic matter 7%), and 10g The hydrochloric acid solution (10wt%) was mixed and transported into the reactor B to react at normal temperature and pressure, the stirring speed was 500r / min, and the residence time was 10min.

[0044] (2) The gas generated by the reaction is exported into the lye absorber A and absorbed by saturated calcium hydroxide solution at a rate of 30L / h at normal temperature and pressure to remove sulfur dioxide and carbon dioxide gas. The content of sulfur dioxide in the gas phase after absorption meets the environmental protection emission requirements.

[0045] (3) After the reaction, the solid-liquid mixture obtained enters the filter C for normal pressure filtration a...

Embodiment 2

[0048] A method for treating sulfur-containing mud, the steps are as follows:

[0049] (1) 50g of sulfur-containing mud obtained in the production process (wherein the mass fraction of each component is about: water 45%; sodium chloride 23%; sodium thiosulfate 15%; sulfur 10%; organic matter 8%), and 50g hydrochloric acid solution (5wt%) was mixed and transported to reactor B to react at normal temperature and pressure, the stirring speed was 800r / min, and the residence time was 5min.

[0050] (2) The gas generated by the reaction is exported into the lye absorber A and absorbed at normal temperature and pressure using 2wt% sodium hydroxide solution at a dosage of 30L / h to remove sulfur dioxide and carbon dioxide gas. The content of sulfur dioxide in the gas phase after absorption meets environmental protection emission requirements.

[0051] (3) After the reaction, the solid-liquid mixture obtained enters the filter C for normal pressure filtration and separation, and the cru...

Embodiment 3

[0054] (1) 50g of sulfur-containing mud produced by adopting pesticide intermediates (wherein the mass fraction of each component is about: water 46%; sodium chloride 27%; sodium thiosulfate 7%; sulfur 13%; organic matter 7%), and 40g The hydrochloric acid solution (3wt%) was mixed and transported into the reactor B to react at normal temperature and pressure, the stirring speed was 600r / min, and the residence time was 10min.

[0055] (2) The gas generated by the reaction is exported into the lye absorber A and absorbed by saturated calcium hydroxide solution at a rate of 30L / h at normal temperature and pressure to remove sulfur dioxide and carbon dioxide gas. The content of sulfur dioxide in the gas phase after absorption meets the environmental protection emission requirements.

[0056] (3) After the reaction, the solid-liquid mixture obtained enters the filter C for normal pressure filtration and separation, and the crude sulfur product is recovered, wherein the sulfur content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com