Dry type anaerobic fermentation biogas slurry solid-liquid separation system and dry type anaerobic fermentation biogas slurry solid-liquid separation method for fruit and vegetable garbage

A technology of dry anaerobic fermentation and solid-liquid separation, which is applied in the field of solid-liquid separation system for dry anaerobic fermentation of fruit and vegetable waste, can solve problems such as equipment wear and water pump blockage, achieve stable sand removal, prevent water pump blockage, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

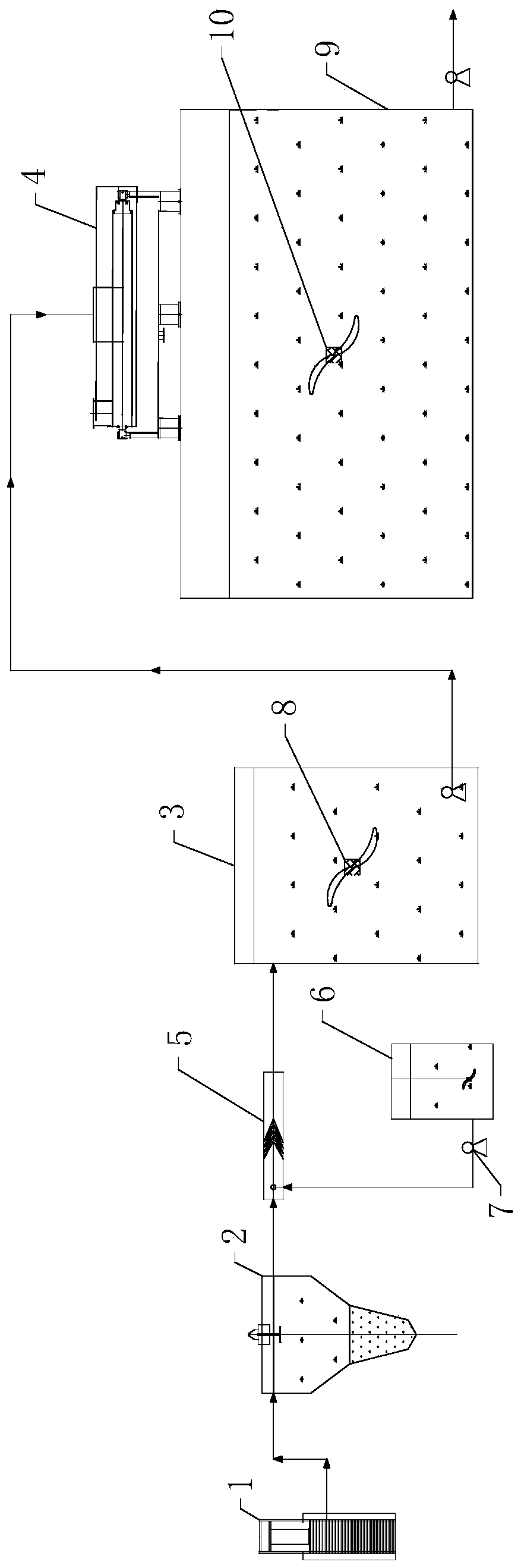

[0029] Such as figure 1 As shown, a dry-type anaerobic fermentation biogas slurry solid-liquid separation system for fruit and vegetable waste includes a mechanical grid 1 , a cyclone settler 2 , a flocculation tank 3 and a centrifugal dehydrator 4 . The mechanical grid 1 is connected to the pipeline of the cyclone sand settler 2, the sewage outlet of the cyclone sand settler 2 is connected to the pipeline of the flocculation tank 3, and the water outlet of the flocculation tank 3 is connected to the pipeline of the centrifugal dehydrator 4. Among them, the mechanical grid 1 is used to intercept large impurities in the biogas slurry, the cyclone sand settler 2 is used to separate the sand in the biogas slurry, the flocculation tank 3 is used to flocculate the SS in the biogas slurry, and the centrifugal dehydrator 4 It is used to dehydrate the biogas slurry after flocculation. The mechanical grid 1 is provided with a driving mechanism and a transmission mechanism, and the tra...

Embodiment 2

[0035] Such as figure 1 As shown, on the basis of Example 1, this Example 2 provides a solid-liquid separation method for dry anaerobic fermentation of fruit and vegetable waste, using the solid-liquid separation method of dry anaerobic fermentation of fruit and vegetable waste in the first embodiment. A liquid separation system comprising the steps of:

[0036] In step S1, the biogas slurry passes through the mechanical grid 1 to trap large impurities in the biogas slurry, and the trapped impurities are reversed to the other side with the fine grid and then slide down by gravity.

[0037] In step S2, the biogas slurry with trapped impurities flows into the cyclone sand settler 2 to remove sand from the biogas slurry. The biogas slurry forms a vortex state, the sand and gravel settle to the bottom of the sand settler, the organic matter flows out with the sewage, and the deposited sand and gravel are regularly pumped out by the sand and gravel pumping mechanism.

[0038] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com