Method for production of liquid fertilizer from biogas slurry

A liquid and biogas slurry technology, applied in liquid fertilizer, application, nitrogen fertilizer, etc., can solve the problems of high water content, high equipment cost, difficult processing, etc., and achieve high organic matter content, low continuous production, and low solid content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

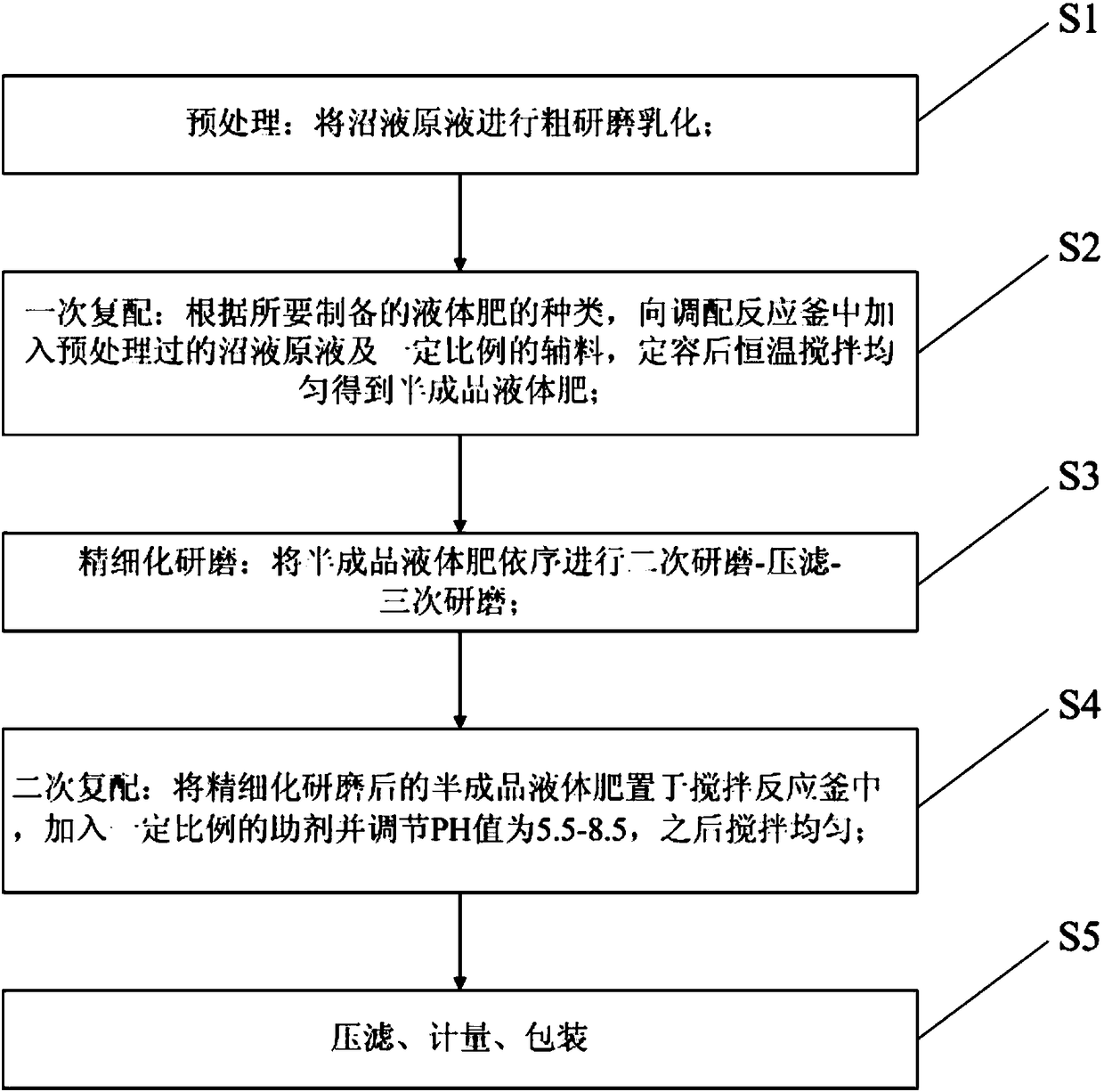

Method used

Image

Examples

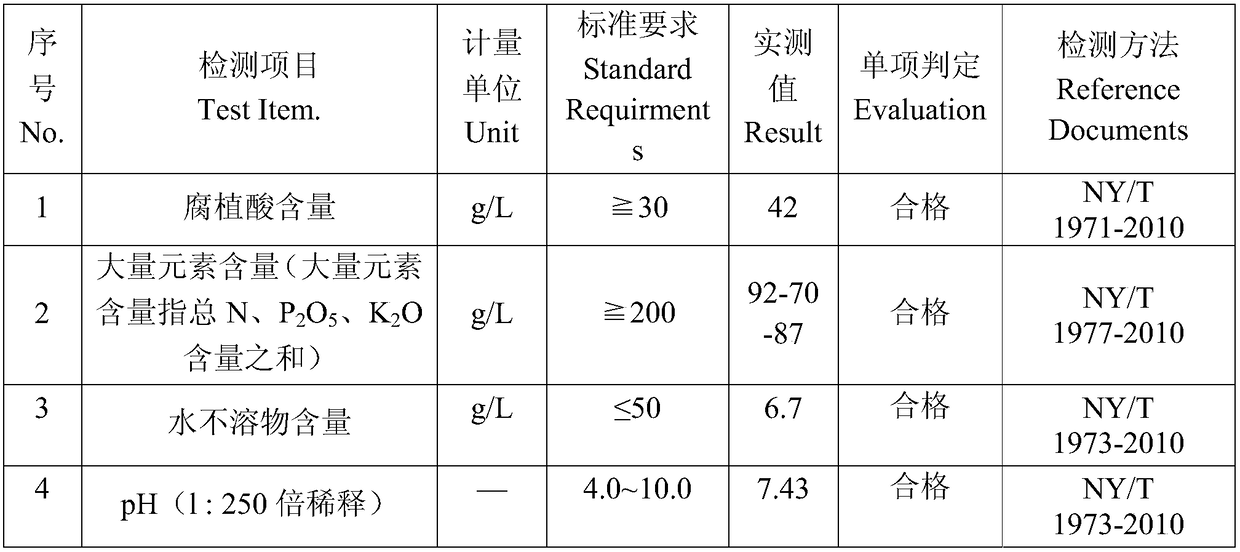

Embodiment 1

[0028] Utilize biogas slurry to produce humic acid-containing water-soluble fertilizer (balanced type), comprising the following steps:

[0029] The first step, pretreatment: use a sand mill to coarsely grind and emulsify the raw liquid of biogas slurry for 5 times;

[0030] The second step, one-time compounding: pump 300kg of biogas slurry that has been coarsely ground by a sand mill for 5 times into the blending reaction kettle through a diaphragm pump, add 60kg of fulvic humic acid at a speed of 150r / min, and add it after it is completely dissolved 195kg UAN solution (specific gravity 1.3g / L), then add 320kg ammonium polyphosphate solution (specific gravity 1.28g / L), and finally add 100kg potassium chloride, after completely dissolving, add biogas slurry stock solution that has been coarsely ground 5 times and set the volume to 1 ton ;Stir and emulsify at 20°C and 500r / min for 20min;

[0031] The third step is fine grinding: the semi-finished liquid fertilizer is ground fo...

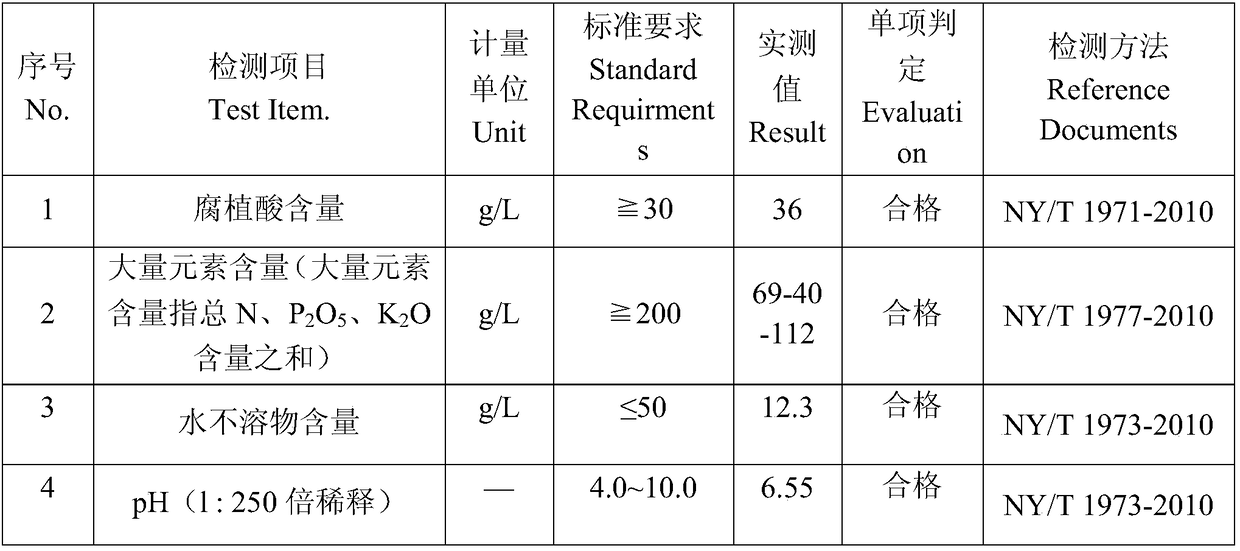

Embodiment 2

[0037] Utilize the biogas slurry to produce the water-soluble fertilizer (high potassium type) containing humic acid, comprising the following steps:

[0038] The first step, pretreatment: use a sand mill to coarsely grind and emulsify the raw liquid of biogas slurry for 5 times;

[0039] The second step, one-time compounding: pump 300kg of biogas slurry that has been coarsely ground by a sand mill for 5 times into the blending reaction kettle through a diaphragm pump, add 60kg of fulvic humic acid at a speed of 150r / min, and add it after it is completely dissolved 234kg UAN solution (specific gravity 1.3g / L), then add 192kg ammonium polyphosphate solution (specific gravity 1.28g / L), and finally add 180kg potassium chloride, after completely dissolving, add biogas slurry stock solution that has been coarsely ground 5 times and set the volume to 1 ton ;Stir and emulsify at 30°C and 500r / min for 30min;

[0040] The third step is fine grinding: the semi-finished liquid fertilize...

Embodiment 3

[0046] The production of amino acid-containing water-soluble fertilizer from biogas slurry comprises the following steps:

[0047] The first step, pretreatment: use a sand mill to coarsely grind and emulsify the raw liquid of biogas slurry for 5 times;

[0048] The second step, one-time compounding: pump 300kg of biogas slurry that has been coarsely ground by a sand mill for 5 times into the blending reaction kettle through a diaphragm pump, add 300kg of amino acid raw powder at a speed of 150r / min, and add 160kg after it is completely dissolved Chelate trace elements (the mass percentages of each element are as follows: Fe4%, Mn2%, Zn5%, B2%), after completely dissolving, add biogas slurry stock solution that has been coarsely ground 5 times and set the volume to 1 ton; at 30°C, 500r / Stir and emulsify for 20 minutes at 1 min;

[0049] The third step is fine grinding: the semi-finished liquid fertilizer is ground for a second time through a colloid mill, and then put into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com