Method for preparing high-purity galactooligosaccharide through synergy of enzymes

A high-purity galacto-oligosaccharide technology, applied in the field of preparation of galactooligosaccharides, can solve the problems of high preparation cost and low purity of high-purity galacto-oligosaccharides, and achieve improved purity and high tolerance. The effect of high removal rate of monosaccharide and monosaccharide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 50g of lactose and add 50g of water to configure 100g of 50% lactose solution, adjust the pH value of the sugar solution to 5.0 with alkali; add 20U / g of β-glucosidase B and 20U / g of β-galactosidase A, The enzyme activity ratio of β-galactosidase A and β-glucosidase B is 1:1; it is maintained at 65°C for 10 minutes, and converted at 45°C for 4 hours, 62.53% galactooligosaccharides, 2.03% lactose, galactose 9.11%, glucose 26.33%. Water bath at 100°C for 5 minutes. After inactivating the enzyme, take 5g of sugar solution and divide it into I solution and II solution. Take 1g of I solution and dilute it with water to 2g (the sugar concentration at this time is about 20%). Add 0.01g of dry yeast powder. Activated at 34°C for 2 hours, then transferred to 4g of II solution and cultured for 6 hours, then directly transferred to the remaining sugar solution, and fermented for 48 hours. Glucose 0.5%. Decolorization: Add activated carbon to the fermented sugar solution fo...

Embodiment 2

[0029] Dissolve lactose in water, heat to dissolve to control the mass concentration of lactose at 60%, adjust the pH of the sugar solution to 5.5 with hydrochloric acid or sodium hydroxide; add β-galactosidase A and 6U / g β-glucose in an amount of 8U / g The enzyme activity ratio of glucosidase B, β-galactosidase A and β-galactosidase B was controlled at 1.33:1; kept at 50°C for 15 minutes, then cooled to 45°C for 6 hours. After conversion, the composition of the sugar liquid is: 55.96% of galacto-oligosaccharides, 9.15% of lactose, 7.31% of galactose, and 29.15% of glucose.

[0030] Enzyme inactivation: 100°C water bath for 10 minutes, then cool to room temperature.

[0031] Preparation of hyperosmotic Saccharomyces cerevisiae: Take 5g of enzyme-inactivating sugar solution, divide it into I solution and II solution, take 2g of I solution, dilute 1.5 times to 5g (sugar concentration is about 20%), add 0.05g of yeast dry powder, and keep at 32°C After 4 hours of lower fermentati...

Embodiment 3

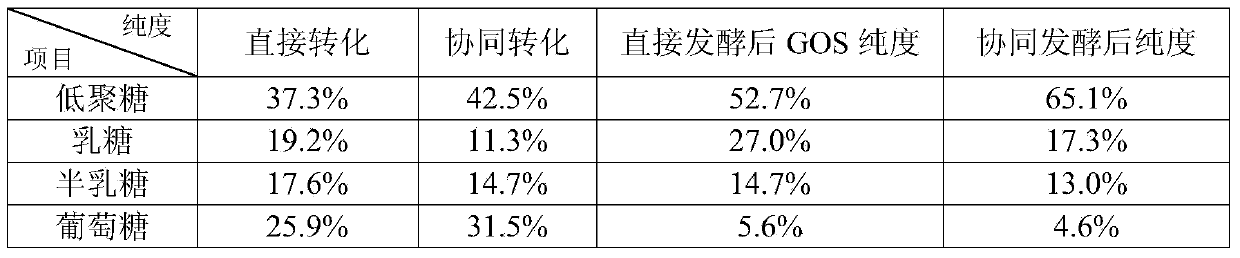

[0038] Weigh 30g of lactose and add 70g of water to configure 100g of 30% lactose solution, adjust the pH value of the sugar solution to 5.0 with hydrochloric acid; add 20.0U / g of β-galactosidase A and 0.4U / g of β -Galactosidase B, the enzyme activity ratio of β-galactosidase A and β-galactosidase B is controlled at 50:1; keep at 55°C for 15 minutes, then lower the temperature to 40°C for 8 hours, boil for 5 minutes Inactivate enzymes. Take 5mL of sugar solution and divide it into liquid I and liquid II. Take 1g of liquid I, dilute it twice to 2g (sugar concentration is about 15%), add 0.004g dry yeast powder, activate at 34°C for 4h, and then transfer to 4g of II After being cultured in the liquid for 6 hours, it was directly transferred to the remaining transformation liquid, and fermented for 16 hours. The results of transformation and fermentation are shown in Table 1.

[0039] Table 1 β-galactosidase separate transformation and embodiment 3 synergistic transformation eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com