Sludge anaerobic digestion-high dryness dehydration method used for achieving adjustable high solid content based on double membrane system synchronous dehydration

An anaerobic digestion, high solid content technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. Affecting cell movement and diffusion, easy formation of feedback inhibition, etc., to achieve the effect of small footprint, stable process operation, and improved process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

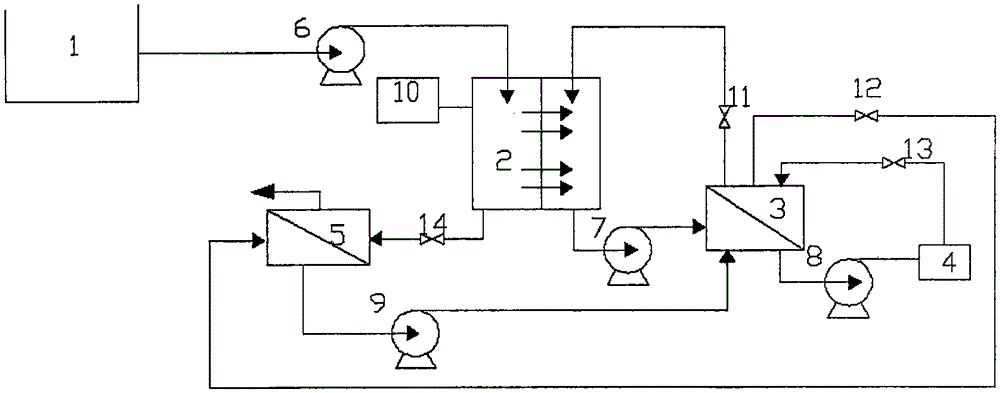

[0041] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0042] Such as figure 1 As shown, an adjustable high solid content sludge anaerobic digestion-high dry dehydration process device based on synchronous dehydration of double-membrane system includes raw sludge tank 1: used to store excess sludge and pre-concentrate it; Forward osmosis anaerobic digestion reactor 2: used for anaerobic reaction and synchronous dehydration of sludge; membrane distillation module 3: used for concentrating forward osmosis draw liquid; membrane distillation drive liquid constant temperature circulation tank 4: used for storage of membrane distillation Clear water produced in the process; high-dry dehydration forward osmosis reactor 5: used for further dehydration of the sludge after anaerobic digestion; raw sludge pump 6: used to pump the raw sludge into the anaerobic reaction of the forward osmosis sludge Forward osm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com