Technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials

A technology of lignocellulose and anaerobic fermentation, which is applied in the field of high-efficiency anaerobic fermentation of lignocellulose-rich materials to produce biogas, can solve the problems of low gas production efficiency, high concentration of backflow biogas slurry, low treatment efficiency, etc. Consumption, improve the level of automation, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

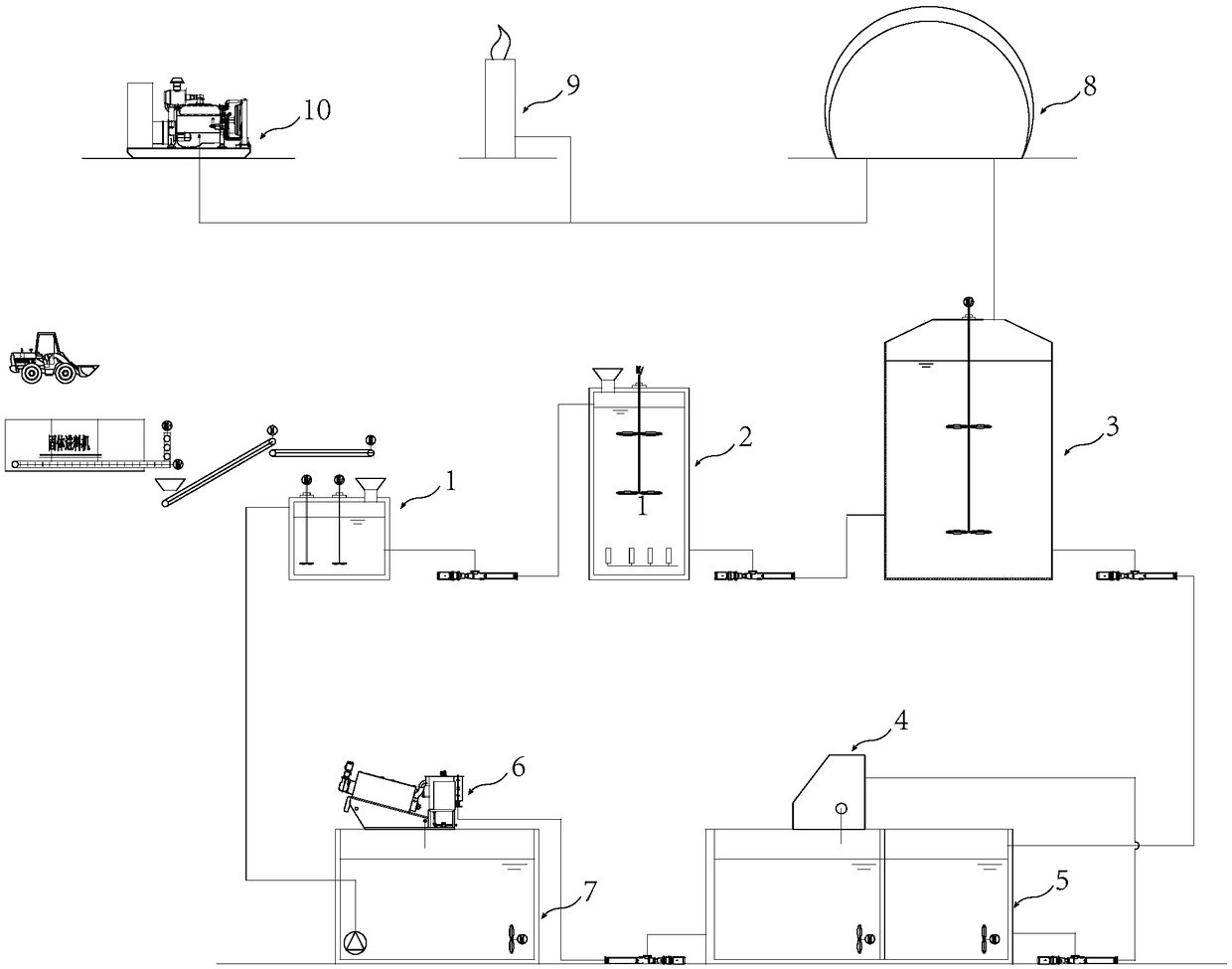

Method used

Image

Examples

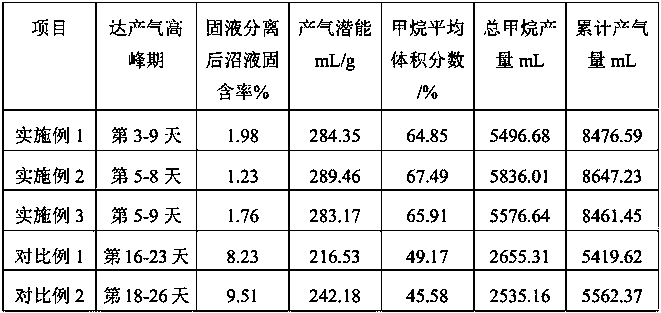

Embodiment 1

[0034] A process method for producing biogas by efficient anaerobic fermentation of lignocellulose-rich materials, comprising the following steps:

[0035] S1. Material beating: mix the roughly broken straw with the returning biogas slurry, and beat it into a slurry in a liquid environment through a beating system. The beating system is installed online with a power of 2kw / m 3 , processing capacity 20 tons per hour, power 15kw, intermittent operation, pulping for 10 minutes after incoming materials;

[0036] S2. Biological treatment: Send the slurry prepared in step S1 to the hydrolysis tank, and add cellulolytic enzyme at the same time to obtain a mixed slurry. The capacity of the cellulolytic enzyme tank is 1kg / 60m 3 ;

[0037] S3. Facultative hydrolysis acid production: In the hydrolysis tank, intermittently aerate, hydrolyze and produce acid, and obtain the pre-treated material. The pH of the hydrolysis tank is 5.6, the temperature is 28°C, and the aeration is 20 minutes ...

Embodiment 2

[0045] A process method for producing biogas by efficient anaerobic fermentation of lignocellulose-rich materials, comprising the following steps:

[0046] S1. Material beating: mix the roughly broken straw with the returning biogas slurry, and beat it into a slurry in a liquid environment through a beating system. The beating system is installed online with a power of 2kw / m 3 , processing capacity of 20 tons per hour, power of 15kw, intermittent operation, pulping for 10 minutes after incoming materials.

[0047] S2. Biological treatment: Send the slurry prepared in step S1 to the hydrolysis tank, and add cellulolytic enzyme at the same time to obtain a mixed slurry. The capacity of the cellulolytic enzyme tank is 1kg / 60m 3 . ;

[0048] S3. Facultative hydrolysis acid production: in the hydrolysis tank, intermittent aeration, hydrolysis and acid production, to obtain pre-treated materials, the pH of the hydrolysis tank is 6.3, the temperature is 33 ° C, aeration is 30 minut...

Embodiment 3

[0056] A process method for producing biogas by efficient anaerobic fermentation of lignocellulose-rich materials, comprising the following steps:

[0057] S1. Material beating: mix the roughly broken straw with the returning biogas slurry, and beat it into a slurry in a liquid environment through a beating system. The beating system is installed online with a power of 2kw / m 3 , processing capacity 20 tons per hour, power 15kw, intermittent operation, pulping for 10 minutes after incoming materials;

[0058] S2. Biological treatment: Send the slurry prepared in step S1 to the hydrolysis tank, and add cellulolytic enzyme at the same time to obtain a mixed slurry. The capacity of the cellulolytic enzyme tank is 1kg / 60m 3 ;

[0059] S3. In the hydrolysis tank, aerate intermittently to produce acid by hydrolysis to obtain pre-treated materials. The pH of the hydrolysis tank is 7, the temperature is 38°C, and the aeration is performed for 40 minutes per hour. Aerated and non-aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com