Food residue and kitchen waste co-processing system and co-processing method

A technology for kitchen waste and kitchen waste, which is applied in the field of co-processing systems for kitchen waste and kitchen waste, can solve the problem of high solid content in the slurry and organic matter loss rate, affecting the stability of the total mixed anaerobic system and the efficiency of manual sorting. Low problems, to achieve the effect of improving equipment utilization, increasing oil extraction process, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

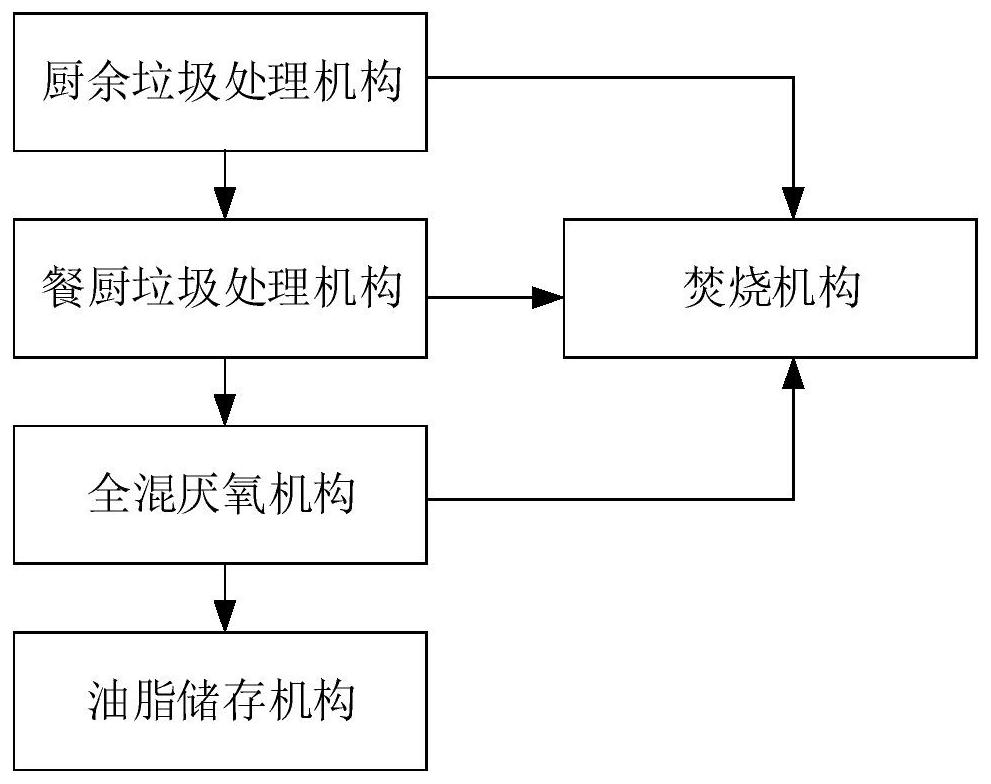

[0025] figure 1 It is a structural block diagram of the kitchen waste and kitchen waste collaborative processing system of the present invention;

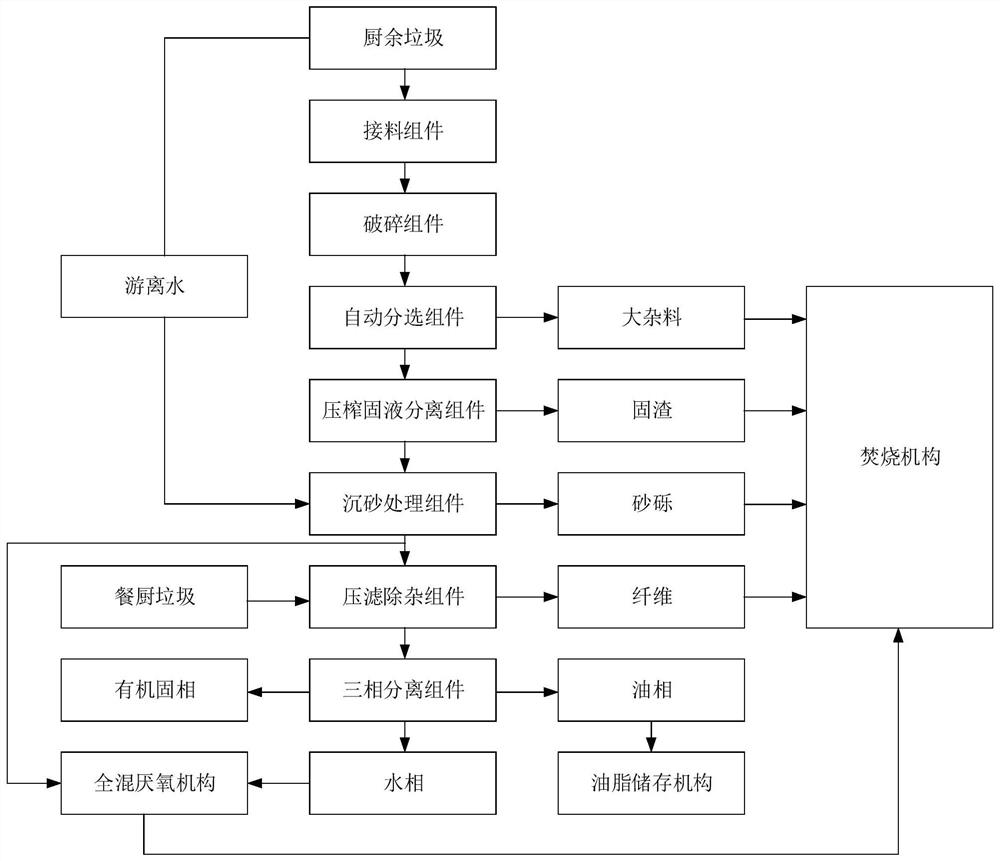

[0026] figure 2 It is a functional block diagram of the kitchen waste and kitchen waste cooperative processing system of the present invention.

[0027] In this example, if figure 1 , figure 2 As shown, this embodiment provides a system for co-processing kitchen waste and food waste, which includes: a kitchen waste treatment mechanism, a food waste treatment mechanism, a fully mixed anaerobic mechanism, an incineration mechanism, and a grease storage mechanism; The food waste treatment mechanism is suitable for separating food waste into solid slag and slurry, that is, the food waste treatment mechanism is suitable for hydraulically filtering the food waste and the slurry produced by the food waste treatment mechanism to remove impurities, three-phase Separation to obtain solid slag, organic solid phase, water phase and oil p...

Embodiment 2

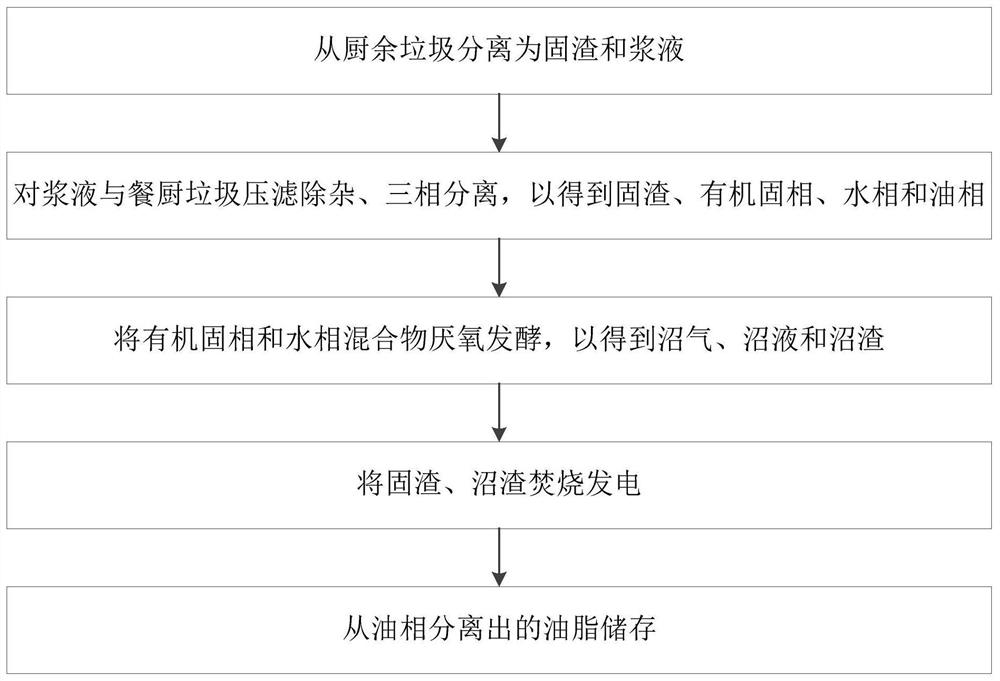

[0048] image 3 It is a flow chart of the method for co-processing kitchen waste and kitchen waste of the present invention.

[0049] On the basis of Example 1, such as image 3 As shown, this embodiment provides a method for co-processing kitchen waste and kitchen waste, which includes: separating the kitchen waste into solid residue and slurry; filtering the slurry and kitchen waste to remove impurities and three-phase separation to Obtain solid residue, organic solid phase, water phase and oil phase; anaerobically ferment organic solid phase and water phase mixture to obtain biogas, biogas slurry and biogas residue; incinerate solid residue and biogas residue to generate electricity; and separate from oil phase out of the grease storage.

[0050] In this embodiment, the method for co-processing kitchen waste and food waste is suitable for processing food waste and food waste by using the system for co-processing food waste and food waste as provided in Embodiment 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com