System and method for electrochemically treating high-viscosity fracturing flow-back fluid

A fracturing flowback fluid and treatment system technology, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc. The effect of secondary treatment cost, resource and cost saving, and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

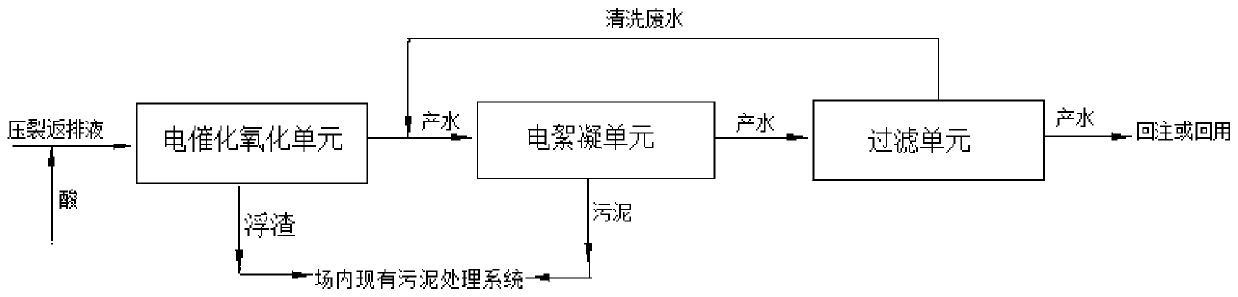

Method used

Image

Examples

Embodiment 1

[0034] A certain high-viscosity fracturing flowback fluid is treated by using the treatment system and method as described above in the present invention, wherein the viscosity of the fracturing flowback fluid is 10.5mPa·s, the oil content is about 150mg / L, the suspended matter is about 500mg / L, and the COD About 1800mg / L. The whole process includes:

[0035] 1) The fracturing flowback fluid is lifted by the pump and enters the electrocatalytic oxidation equipment. At the same time, concentrated sulfuric acid is used on the water inlet pipe to adjust its pH value to 6. The effective reaction time is 45 minutes under the action of electricity, and the current density is 30mA / cm 2 , to carry out oxidative colloid breaking, viscosity reduction, demulsification and air flotation on the fracturing flowback fluid, and the effluent is lifted by the pump and enters the high-frequency pulse electroflocculation equipment;

[0036] 2) The produced water after the electrocatalytic oxidat...

Embodiment 2

[0040] A certain high-viscosity fracturing flowback fluid is treated with the above-mentioned treatment system and method of the present invention, wherein the viscosity of the fracturing flowback fluid is 80.2mPa·s, the oil content is about 1000mg / L, the suspended matter is about 1140mg / L, and the COD About 6300mg / L. The entire treatment process of the fracturing flowback fluid is similar to that of Example 1, and will not be described in detail here.

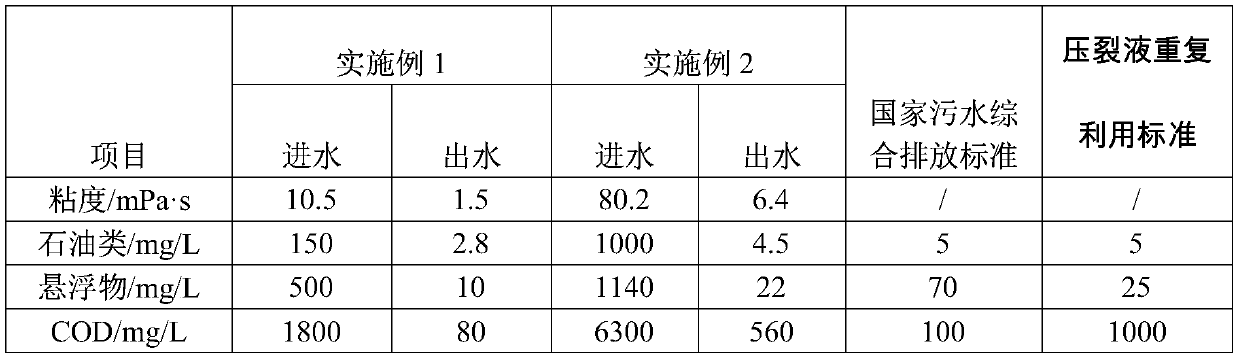

[0041] Table 1 shows the treatment results of the fracturing flowback fluid in Embodiment 1 and Embodiment 2:

[0042] The processing result of table 1 embodiment 1 and embodiment 2

[0043]

[0044] From the treatment results in Table 1, it can be seen that the combined process of pH adjustment, electrocatalytic oxidation and high-frequency pulse electrocoagulation of the present invention can achieve good treatment effect on the effluent, and the petroleum, suspended solids and COD can meet the oilfield follow-up biochem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com