Insert plate device capable of walking on blown-filled mud soil

A plug-in device and silt filling technology, which is applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of heavy self-weight and limited site bearing capacity of onshore plug-in machines, and achieve the effect of improving depth and foundation treatment. , Improve the construction speed and reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical idea and working principle of the present invention:

[0014] The floating cabin provides buoyancy to make the sludge slipper float on the dredger fill. The motor drives the plate impeller to rotate and cut the silt. According to the principle of force and reaction force, the silt provides a reaction force to drive the sludge slipper to move in place. After being in place, the hoist controls the inserting machine to insert the plastic drainage plate.

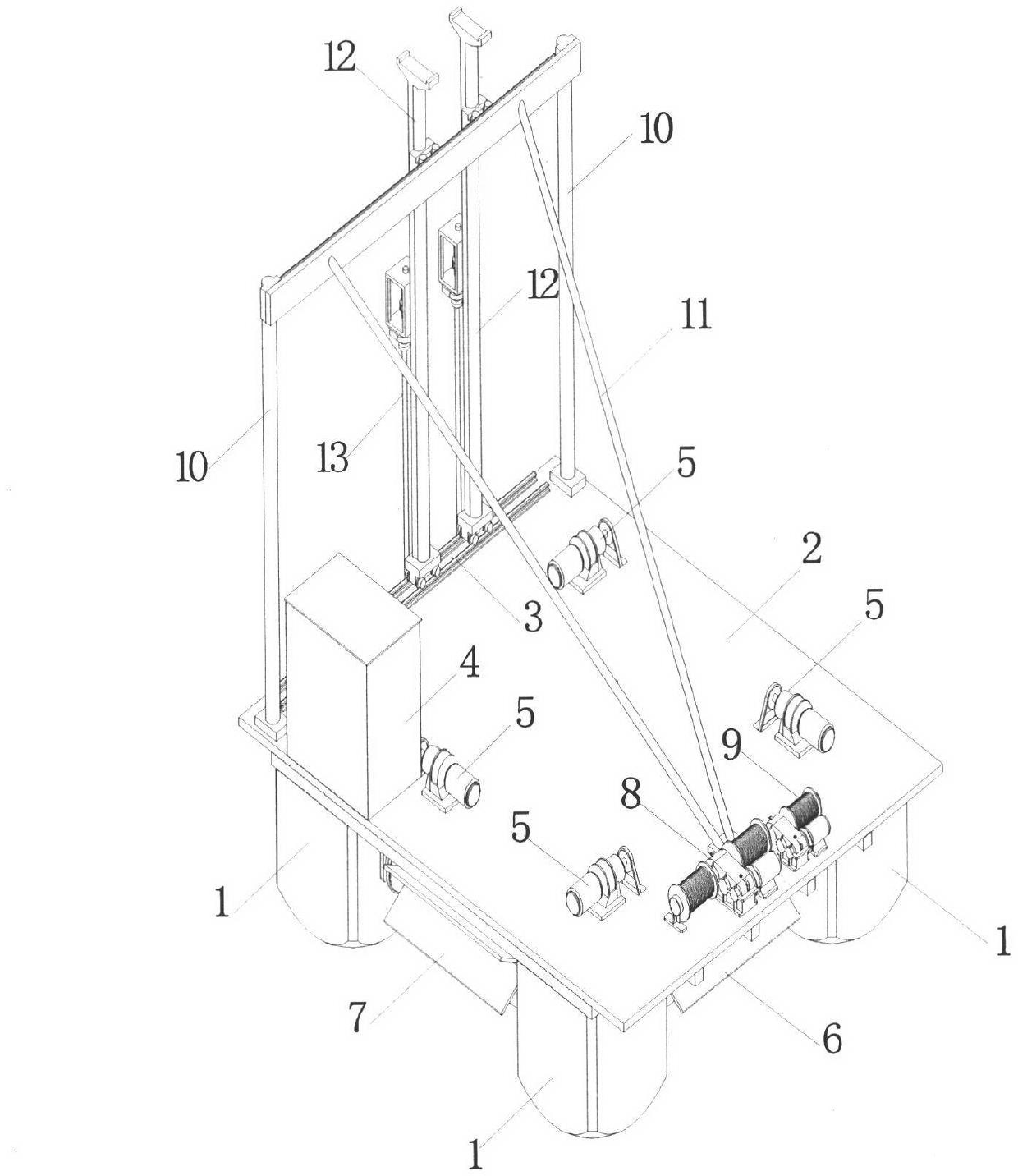

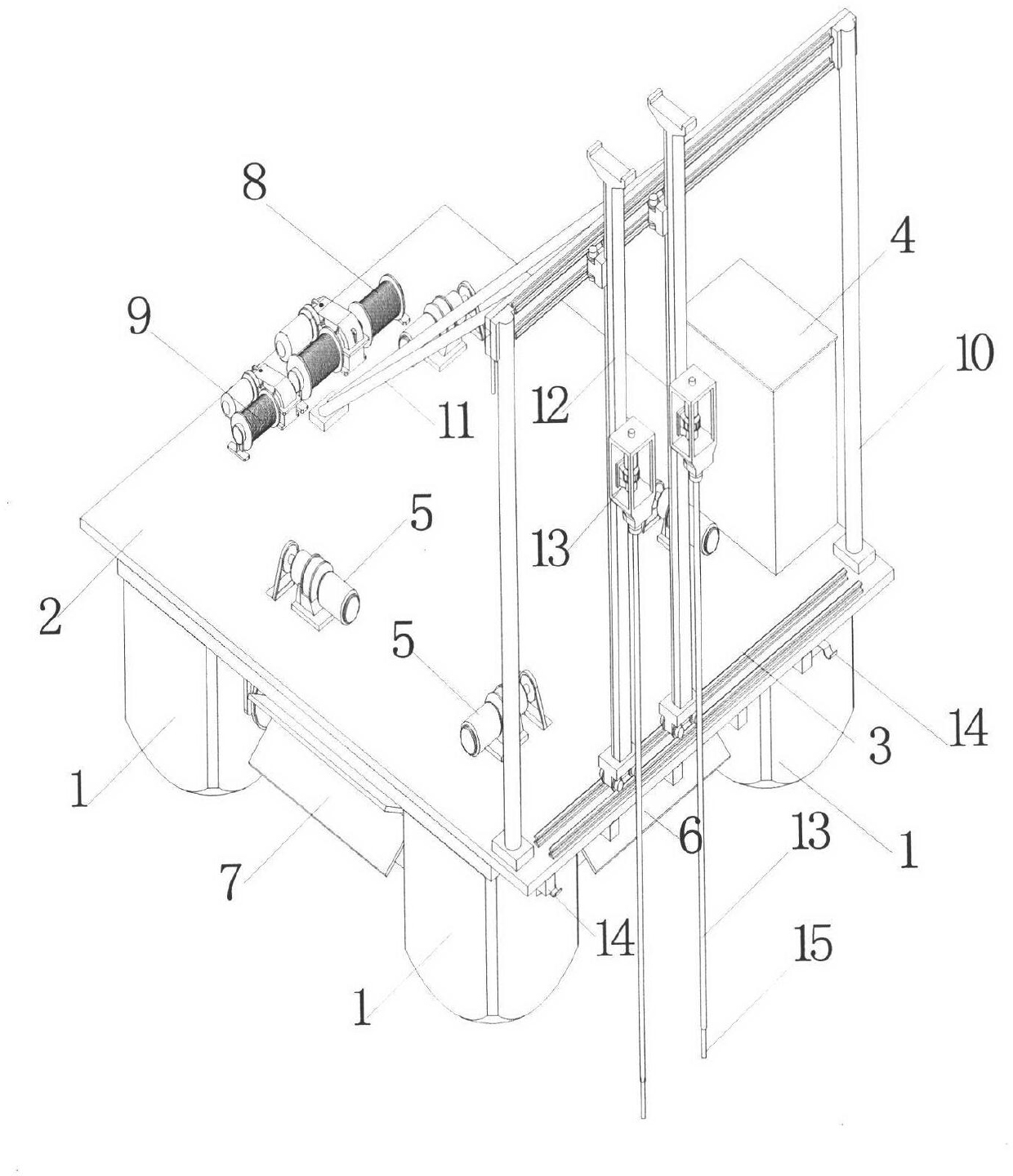

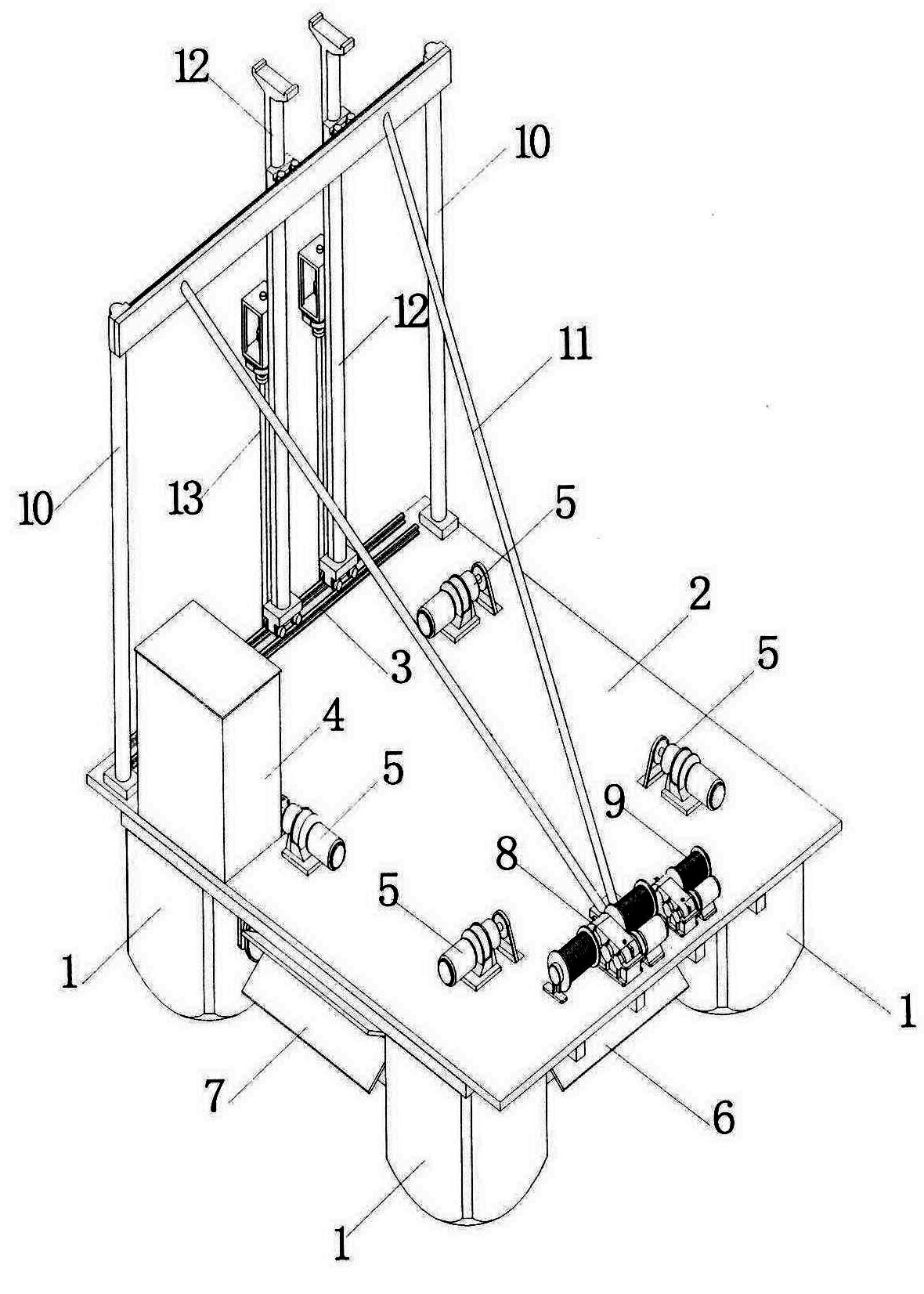

[0015] The following is the specific structure description, such as figure 1 , figure 2 Shown:

[0016] There are 4 floating cabins 1, the upper part of the floating cabin 1 is fixedly connected with the operation platform 2, and the lower part of the operation platform 2 and the floating cabin 1 are installed with 2 horizontal plate impellers 6 and vertical plate impellers 7, and there are 4 electric motors 5 in total. Installed on the operating platform 2, each motor 5 is connected to a horizontal plate impell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com