Water-free atmospheric vacuum distillation technology and device

An atmospheric and vacuum distillation and process technology, which is applied in vacuum distillation, distillation control/regulation of hydrocarbon oil, etc., can solve the problems of easy coking of oil products, reducing the operation stability of the device, and increasing the investment cost of energy consumption and equipment of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

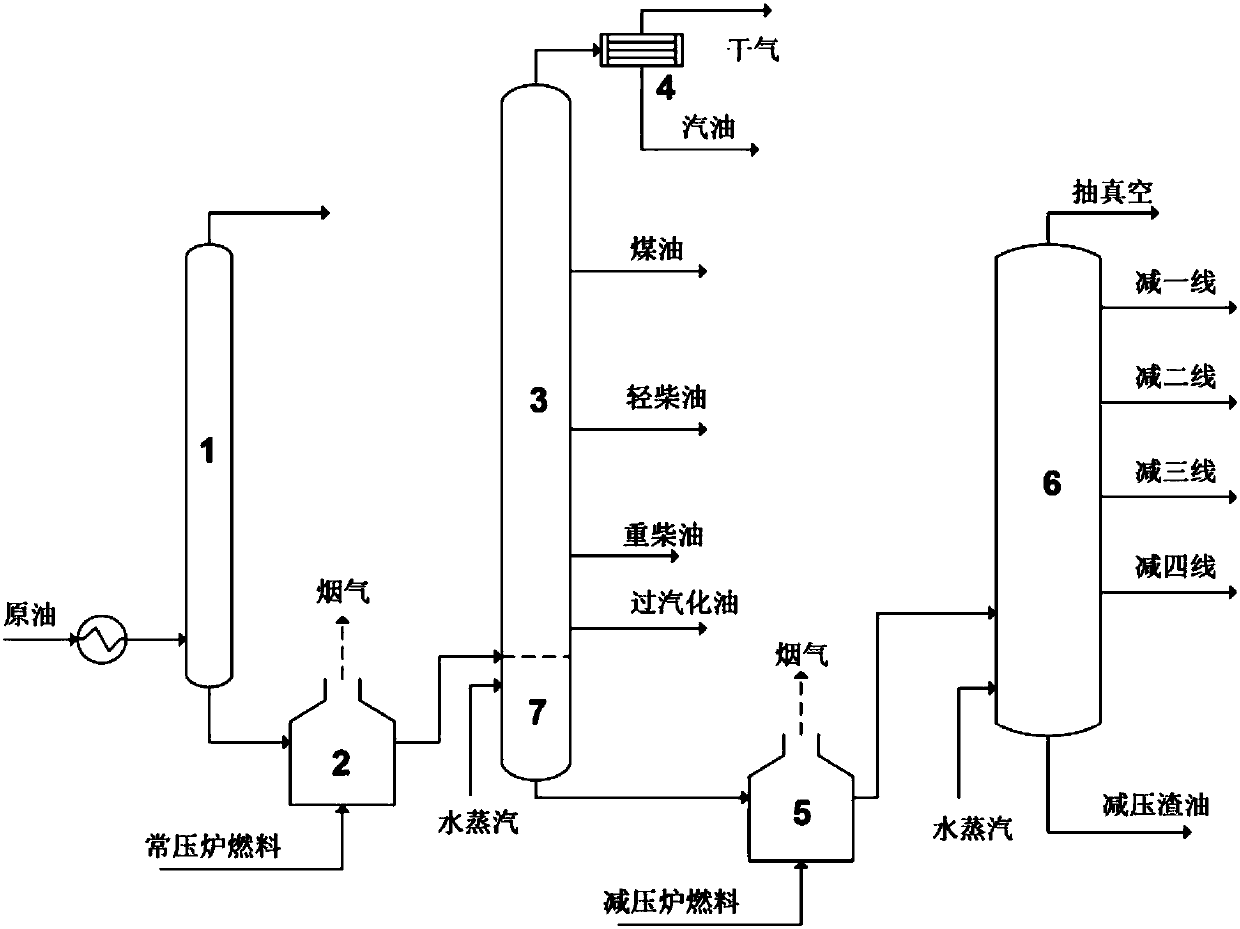

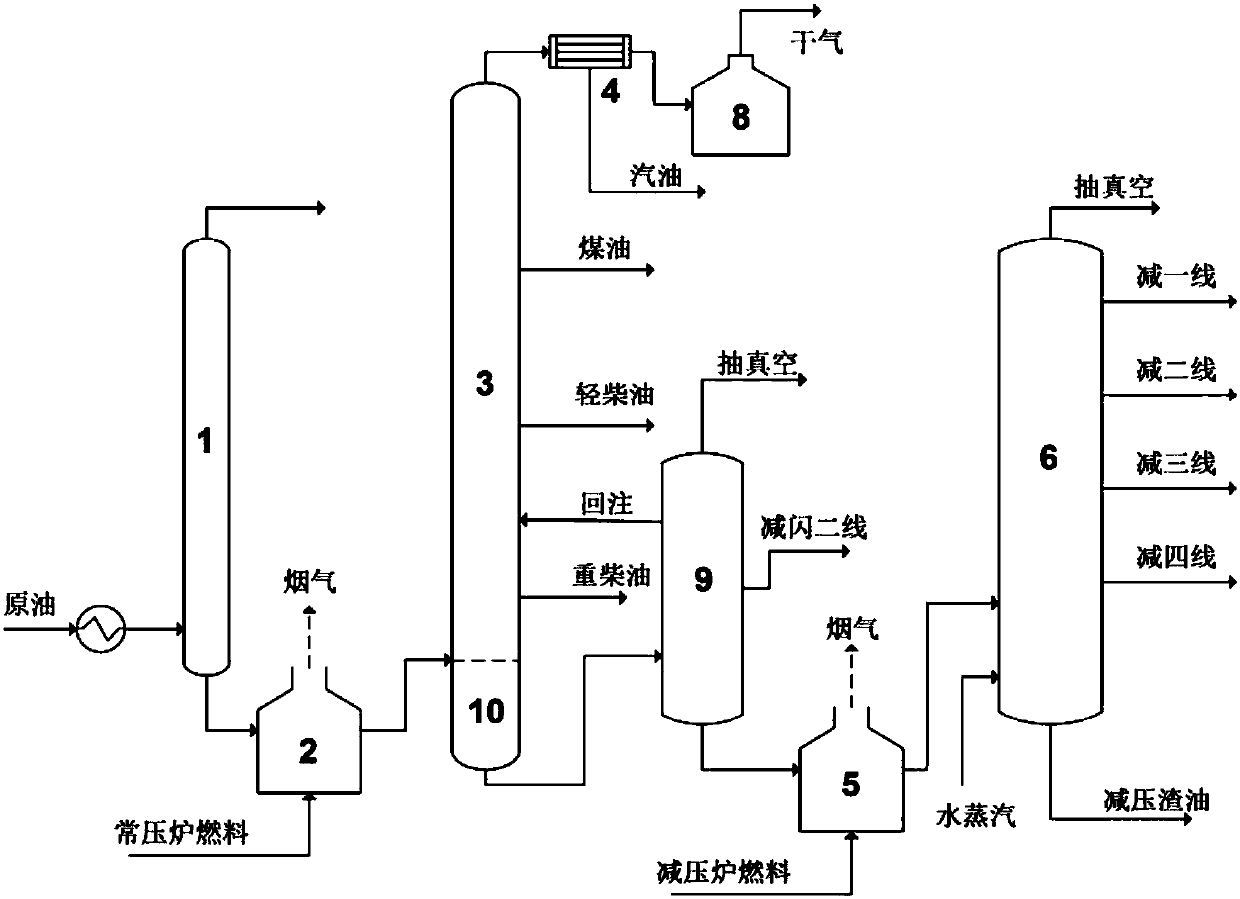

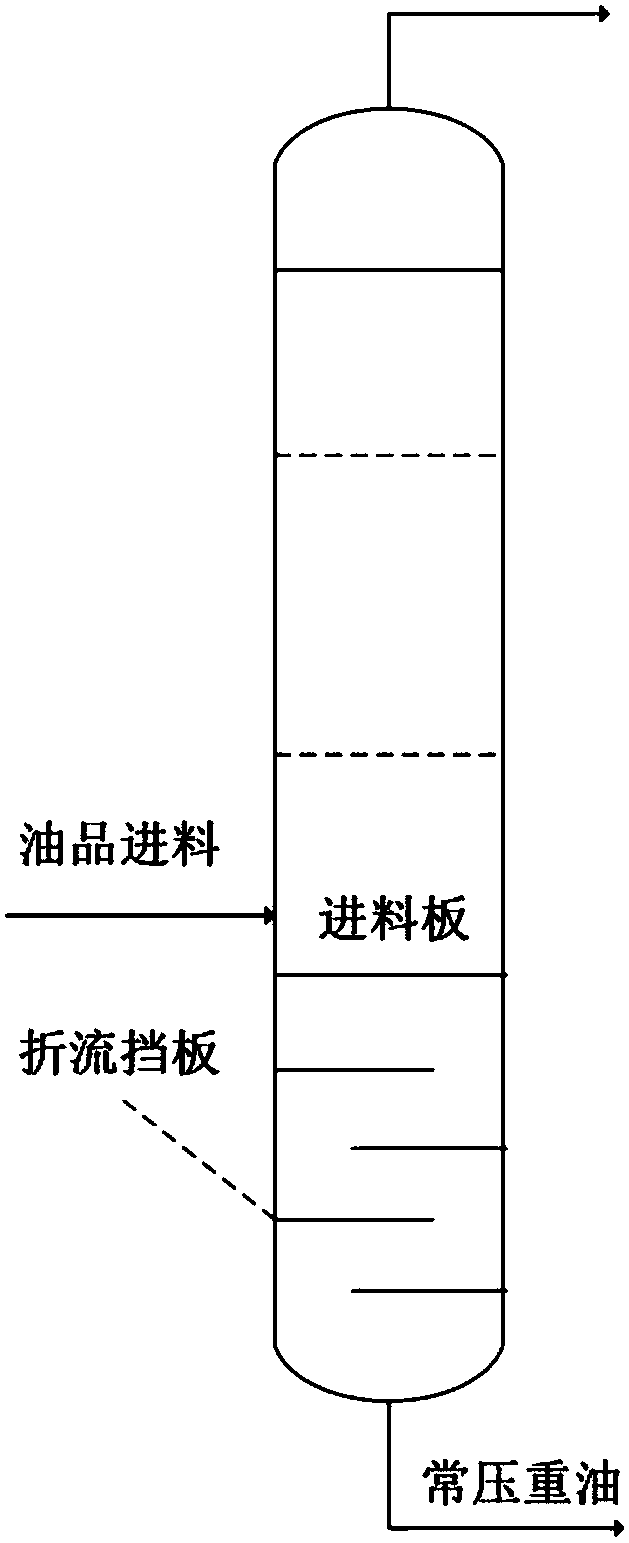

[0078] This embodiment provides a kind of anhydrous atmospheric and vacuum distillation device, its structure is as follows figure 2 shown. The anhydrous atmospheric and vacuum distillation device includes: initial distillation tower 1, atmospheric furnace 2, atmospheric tower 3, vacuum flash tower 9, vacuum furnace 5, vacuum tower 6, condenser 4, alkali washing tank 8 , reboiler;

[0079] Wherein, the primary distillation column 1 is provided with a crude oil inlet, a bottom outlet and a top outlet;

[0080] The atmospheric furnace 2 is provided with a fuel inlet, an oil inlet, a flue gas outlet and an oil outlet, and the bottom outlet of the primary distillation tower 1 is connected with the oil inlet of the atmospheric furnace 2;

[0081] The atmospheric tower 3 is provided with a bottom inlet, a bottom outlet, a first side outlet, a return injection inlet, a second side outlet, a third side outlet, and a top outlet; the oil outlet of the atmospheric furnace 2 communicat...

Embodiment 2

[0088] This embodiment provides a new process for anhydrous atmospheric and vacuum distillation, which is carried out by using the device in Example 1, and its flow process is as follows figure 2 shown. The process includes the following steps:

[0089] After the crude oil is desalted and dehydrated by electricity, it is heated to about 230°C and enters the primary distillation tower 1;

[0090]The oil at the bottom of the initial distillation tower 1 enters the atmospheric furnace 2, and after being heated to 360-370°C, it enters the atmospheric tower 3 for fractionation, and each side line is stripped through a reboiler to obtain naphtha, heavy diesel oil, light diesel oil, Kerosene, the dry gas produced by fractional distillation enters the alkali washing tank 8 after passing through the condenser 4 at the top of the tower, and the HCl, H therein 2 S gas is taken off, and the gasoline that condenser 4 obtains is exported as product;

[0091] The heavy oil in the bottom ...

Embodiment 3

[0094] The flow simulation is carried out with heavy Daria crude oil as the raw material of the atmospheric and vacuum unit, and the density at 20°C is 0.9078g / cm 3 . A 500,000-ton / year conventional atmospheric and vacuum plant and an anhydrous atmospheric and vacuum plant are designed respectively. See Table 1 for comparison of plant parameters.

[0095] Through PRO / II 9.2 software simulation, the effect comparison between conventional atmospheric and vacuum technology and anhydrous atmospheric and vacuum technology can be obtained, see Table 2 and Table 3.

[0096] It can be seen from the data in Table 2 and Table 3 that in the anhydrous atmospheric and vacuum process, there is no water vapor in the atmospheric column, so there will be no condensation of water vapor at the top of the atmospheric column, and the corrosive medium HCl cannot It dissolves in water to form a strong acid, which is removed as the oil and gas enter the alkali washing tank, eliminating the low-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com