Ground effect vehicle wing structure capable of being quickly disassembled

A ground-effect aircraft and wing structure technology, which is applied to aircraft, wings, seaplanes, etc., can solve the problems of inability to install and disassemble easily and quickly, and cannot meet the rapid conversion of various use modes, and achieves to improve the speed of installation and disassembly. , Reduce the difficulty of installation and disassembly, and improve the effect of practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

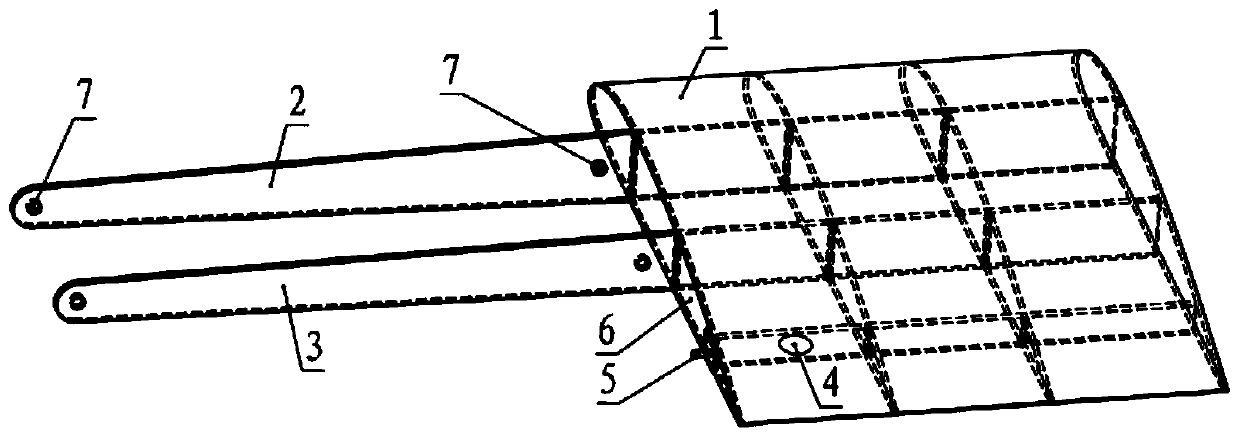

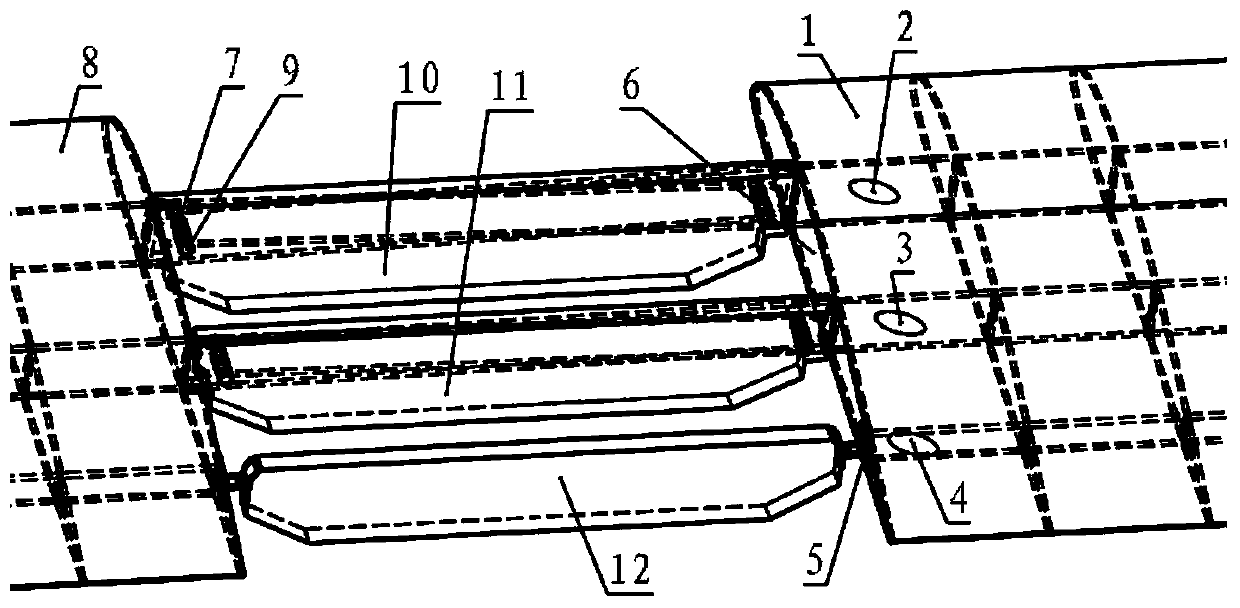

[0022] figure 1 is the schematic diagram of the right wing structure, figure 2 Schematic diagram of left and right wing installation, combined with figure 1 and figure 2 As shown, the present embodiment provides a quick-detachable ground effect aircraft wing structure, the wing structure includes a left wing 8 and a right wing 1, and the structure of the left wing 8 and the right wing 1 is the same; and the left The wing 8 and the right wing 1 are respectively detachably connected to the left and right sides of the hull reinforcement.

[0023] Such as figure 1 As shown, the right wing 1 includes a front beam 2, a middle beam 3 and at least one root rib 6, and one end of the front beam 2, the middle beam 3 is connected with the root rib 6; the other end of the front beam 2, the middle beam 3 is inserted into the hull Reinforcement part, and is detachably connected with hull reinforcement part by pin 9. The root rib 6 is provided with a positioning piece. When the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com