Eccentric screw bolt and its assemblage and construction method

A technology of eccentric bolts and construction methods, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of unfavorable adjustment of the horizontal and vertical joints of the curtain wall system, and the excessive number of ordinary bolts, so as to improve labor production efficiency, strong operability, and guarantee safe and tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

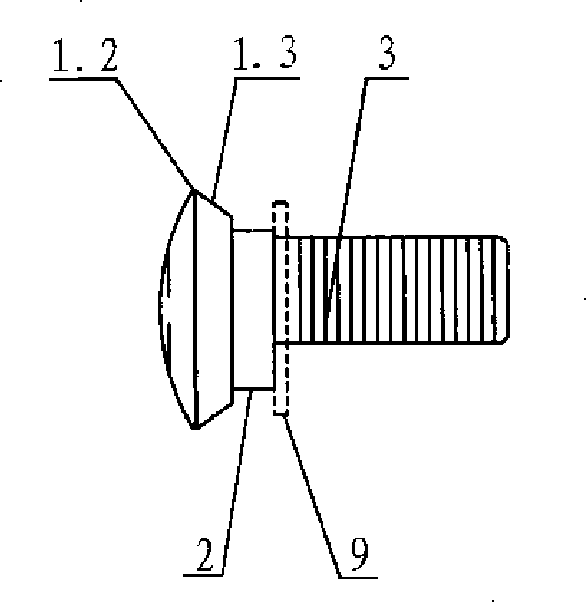

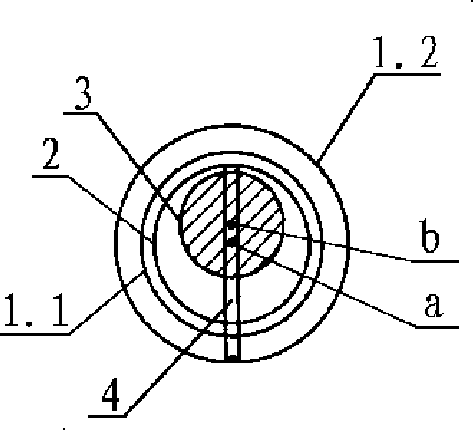

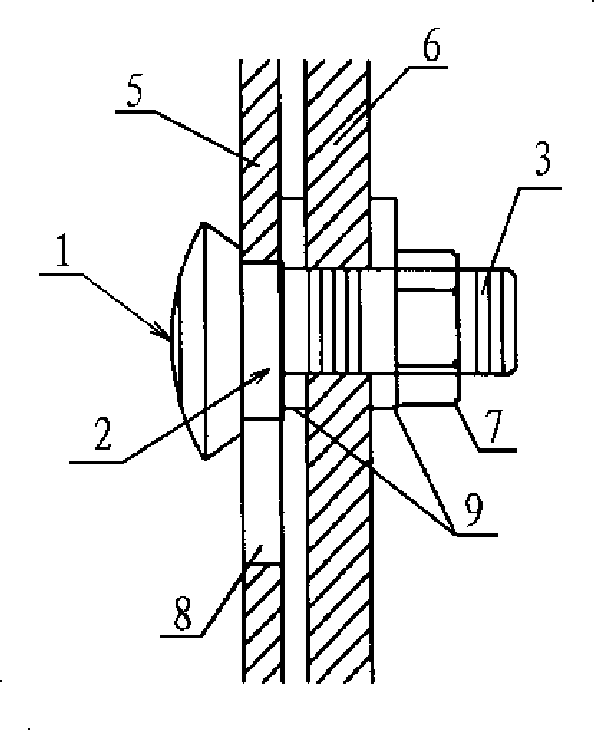

[0036] Examples see figure 1 As shown, this eccentric bolt includes a bolt cap 1, a bolt neck 2, a bolt post 3 and a nut 7 that are all circular in cross-section and connected together, and is characterized in that the diameter of the bolt post 3 is smaller than that of the bolt neck 2 The bolt column and the bolt neck are eccentrically connected, that is, the axis b of the bolt column does not coincide with the axis a of the bolt cap and the bolt neck, and there is a slot 4 on the top surface of the bolt cap. The groove passes through the axis a of the bolt cap and the bolt neck and the axis b of the bolt column at the same time, and one end of the groove passes through the axis a of the bolt cap and the bolt neck and extends to the edge of the top surface of the bolt cap. One end passing through the axis b of the bolt column does not extend to the edge of the top surface of the bolt cap.

[0037] The top surface 1.2 of the above-mentioned bolt cap bulges upwards. The diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com