Table top type microsatellite rapid final assembly operation table

A micro-satellite and operating table technology, applied in the field of operating table, achieves the effect of saving manpower, improving and dismantling speed, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

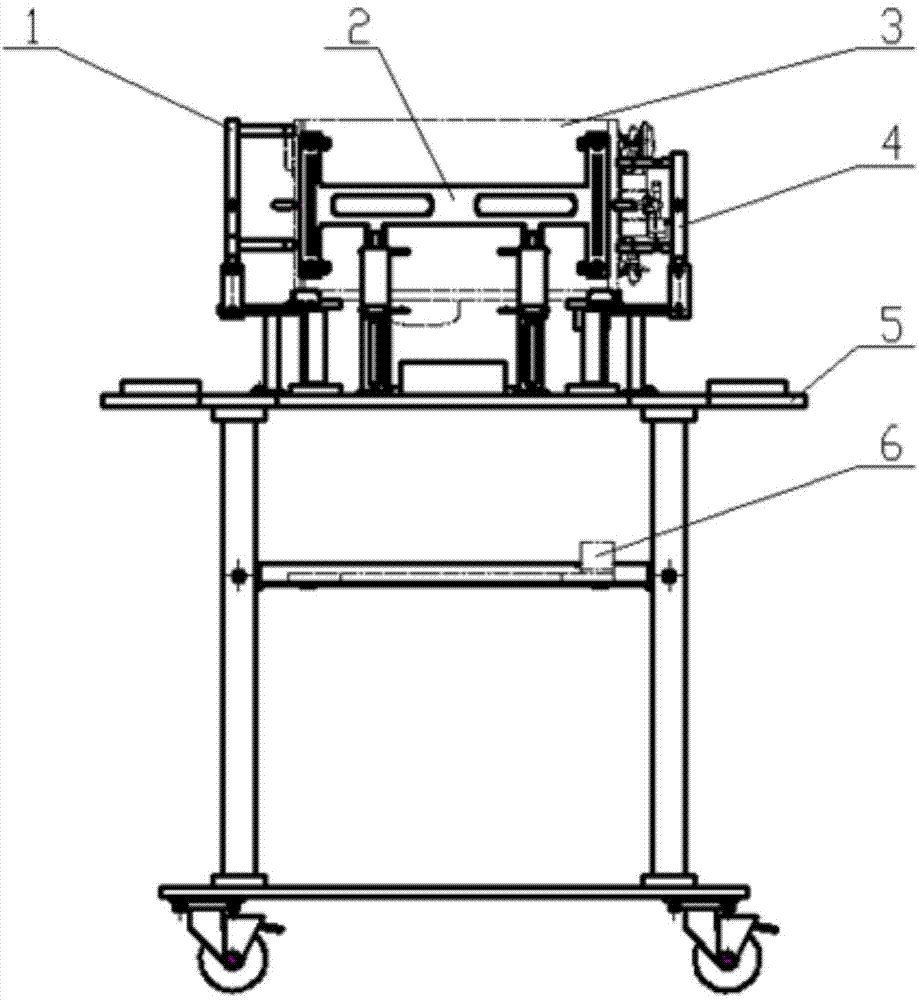

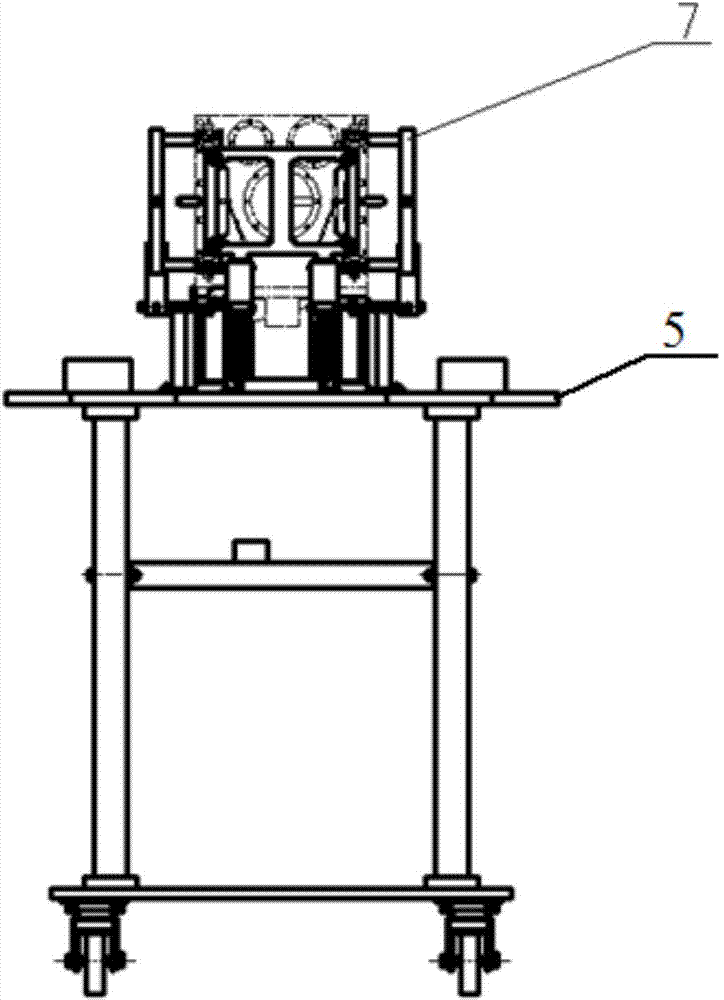

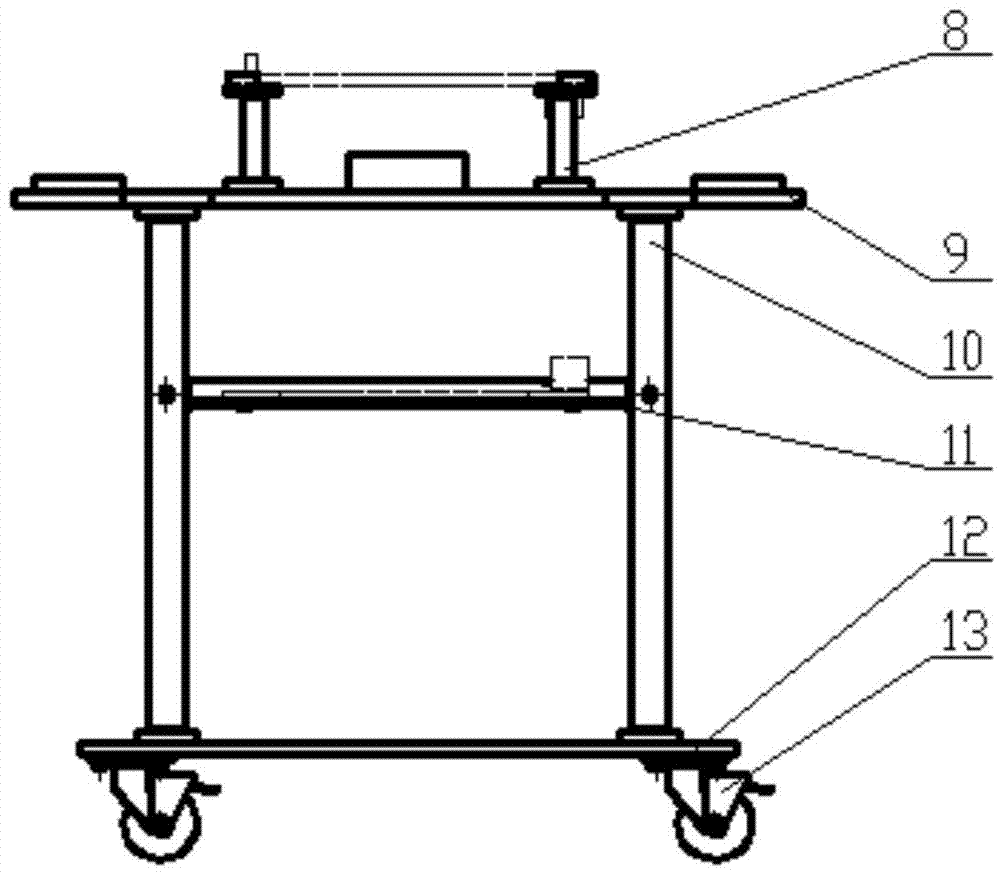

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] Such as Figure 1 to Figure 9 As shown, the table-top micro-satellite fast assembly console of the present invention is composed of a left side panel installation mechanism 1, a front side panel installation mechanism 2, a right side panel installation mechanism 4, an operation platform body 5, and a rear side panel installation mechanism 7. The body 5 is composed of a bottom plate installation support column 8, a table top installation plate 9, a column 10, a drawer assembly 11, a table body bottom plate 12, casters 13, a rubber pad 14, and a positioning block 16. The right side plate installation mechanism 4 is composed of a thumb screw assembly 17 , hinge bracket 18, side plate bracket 19, sleeve 20, rotating rod 21, side plate connecting rod 22, hinge screw 23, and handle 24. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com