Suspension positioning mechanism

A technology of positioning mechanism and positioning parts, applied in installation, optics, instruments and other directions, can solve the problems of difficult to disassemble and assemble moving parts, the roller has no adjustment function, and there is no lifting mechanism, so as to improve the repeated positioning and disassembly speed, improve the The effect of positioning stability and reliability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

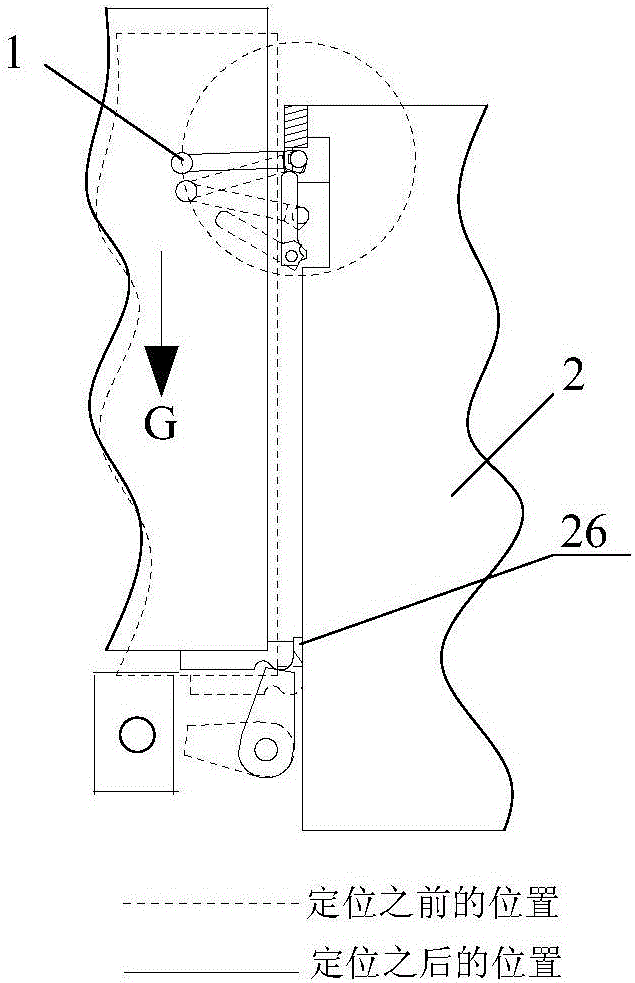

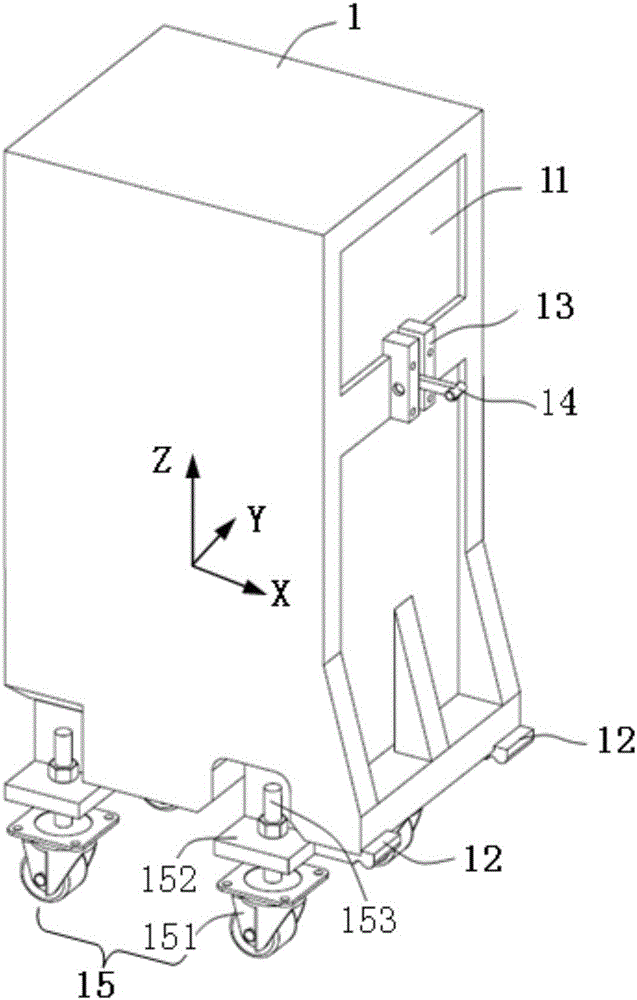

[0033] like figure 1 , 4 As shown, the present invention provides a suspension positioning mechanism, which includes a moving assembly 1 and a stationary assembly 2 .

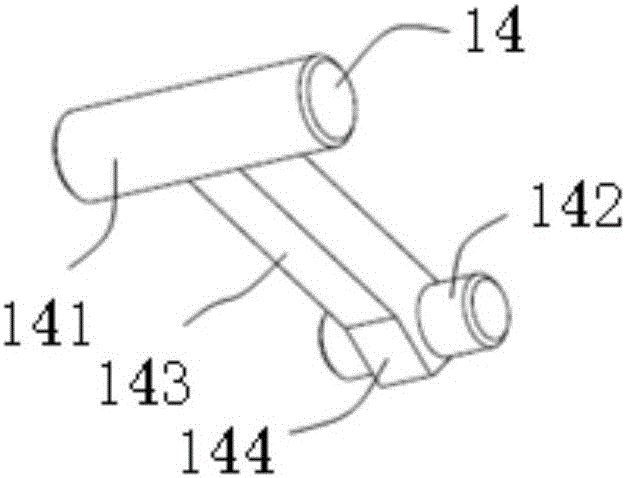

[0034] Wherein the moving assembly 1 comprises a body 11, at least two contact blocks 12 arranged on one side of the body 11, a groove 13, a hook 14 with one end accommodated in the groove 13, and several height-adjustable pulley blocks arranged at the bottom of the body 11 piece 15. like figure 2 As shown, the hook 14 is in the shape of a "worker" as a whole, including a fixed end 141 fixed in the groove 13, a free end 142 and a connecting portion 143 connecting the fixed end 141 and the free end 142, and the connecting portion 143 extends to the free end 142. The outer edge, and a flange 144 is provided at the bottom near the free end 142 . Specifically, two L-shaped baffles are set in the groove 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com