Intelligent omni-directional carrying robot

A handling robot and intelligent technology, applied in the field of robots, can solve the problems of reducing the service life and use effect of omnidirectional wheels, accelerating the wear of the rubber layer, and stretching the rubber layer, so as to improve the speed and convenience of disassembly and assembly, and prevent Stretch phenomenon, effect of improving lagging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

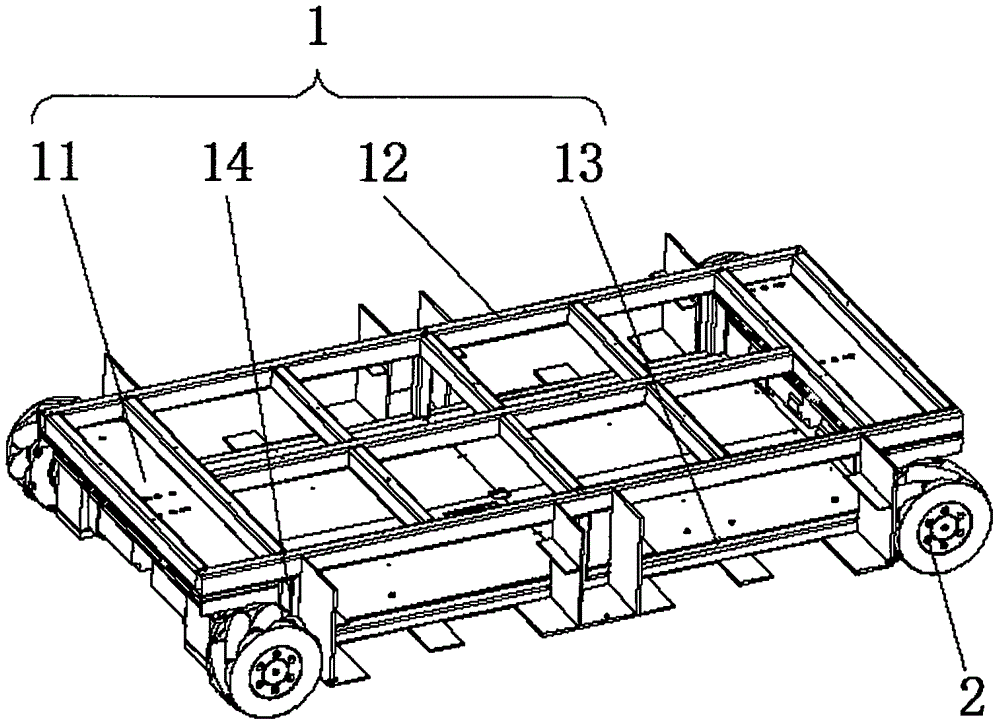

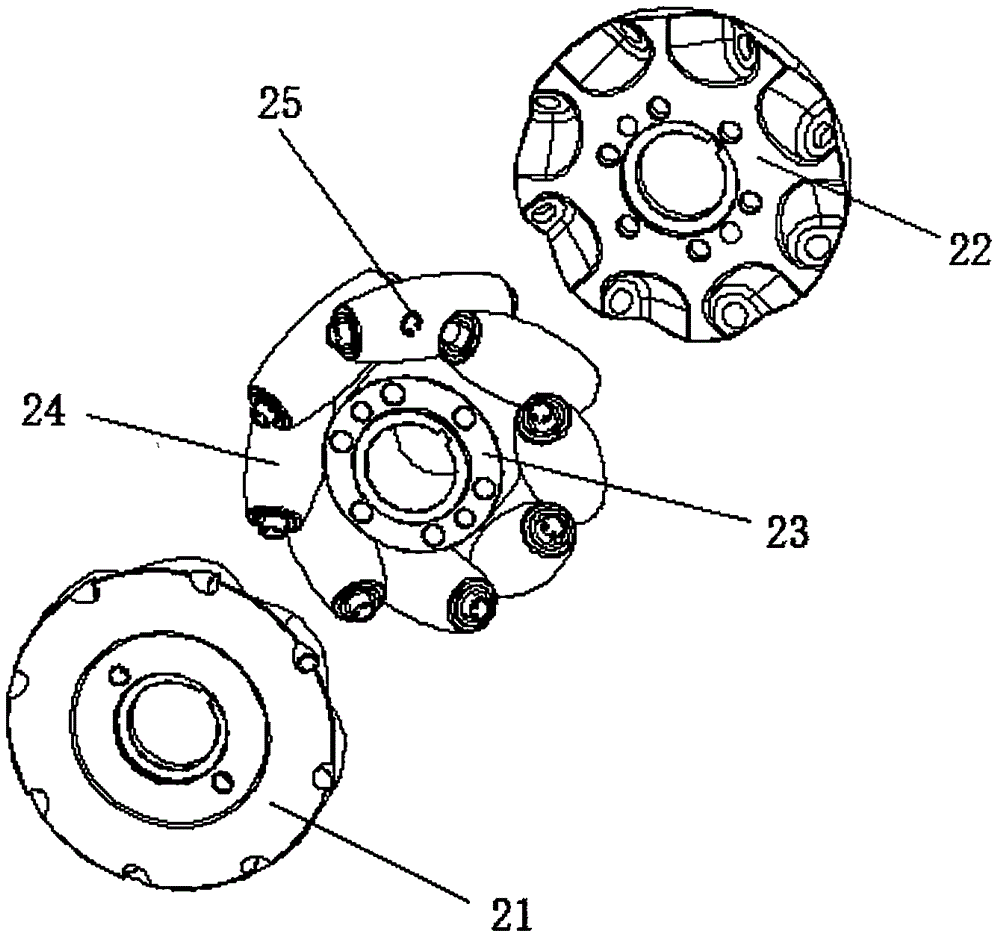

[0035] See Figure 1 to Figure 7 , the present invention has a frame 1 and omnidirectional wheels 2; the omnidirectional wheels 2 are installed on the frame 1; it is characterized in that: the frame 1 includes a reference base plate 11 and an upper frame 12; the reference base plate 11 The upper reference positioning is processed with positioning connection holes; the upper frame 12 is fixedly connected to the reference base plate 11 .

[0036] At the same time, it also includes a lower frame 13; the lower frame 13 is arranged below the upper frame 12; the lower frame 13 is fixedly connected with the upper frame 12 through a connecting beam 14.

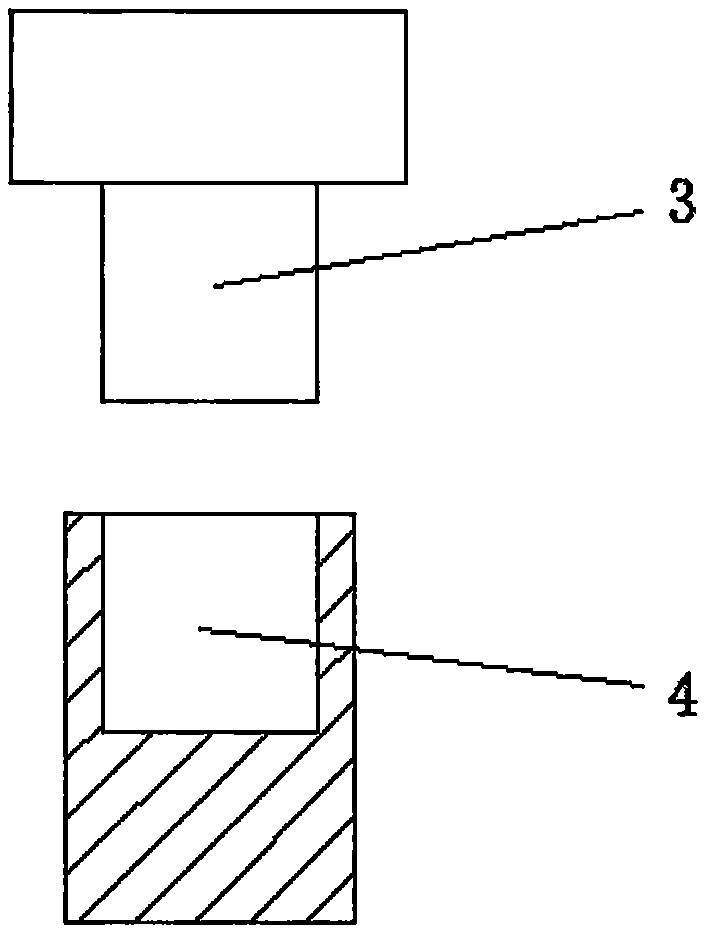

[0037] The two ends of the above-mentioned connecting beam 14 are respectively connected with the upper frame 12 and the lower frame 13 through an in-line structure; the in-line structure includes a block 3 and a slot 4; the upper frame 12 and the lower frame 13 are connected to the The joints of the connecting beam 14 are provided w...

Embodiment 2

[0045] See Figure 1 to Figure 5 and Figure 8 and Figure 9, the present invention has a frame 1 and omnidirectional wheels 2; the omnidirectional wheels 2 are installed on the frame 1; it is characterized in that: the frame 1 includes a reference base plate 11 and an upper frame 12; the reference base plate 11 The upper reference positioning is processed with positioning connection holes; the upper frame 12 is fixedly connected to the reference base plate 11 .

[0046] At the same time, it also includes a lower frame 13; the lower frame 13 is arranged below the upper frame 12; the lower frame 13 is fixedly connected with the upper frame 12 through a connecting beam 14.

[0047] The two ends of the above-mentioned connecting beam 14 are respectively connected with the upper frame 12 and the lower frame 13 through an in-line structure; the in-line structure includes a block 3 and a slot 4; the upper frame 12 and the lower frame 13 are connected to the The joints of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com