Fully-enclosed reduction gearbox assembly

A reduction box, fully enclosed technology, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of not being able to achieve complete closure, and achieve the effect of ensuring concentricity, preventing wear and good sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

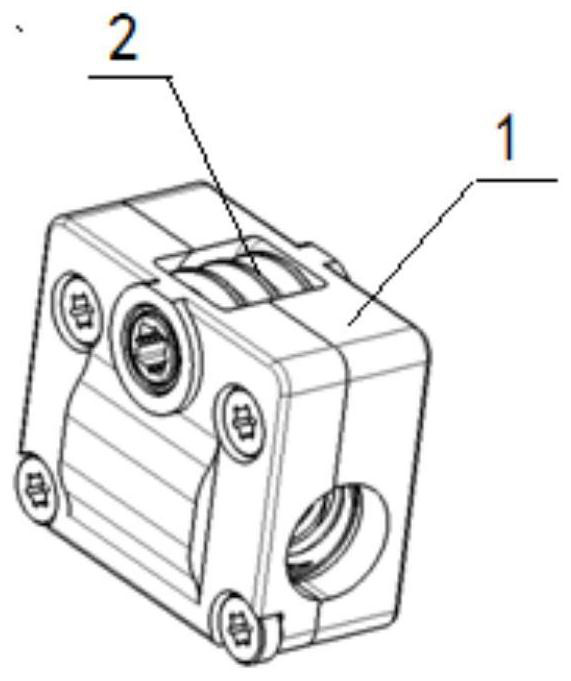

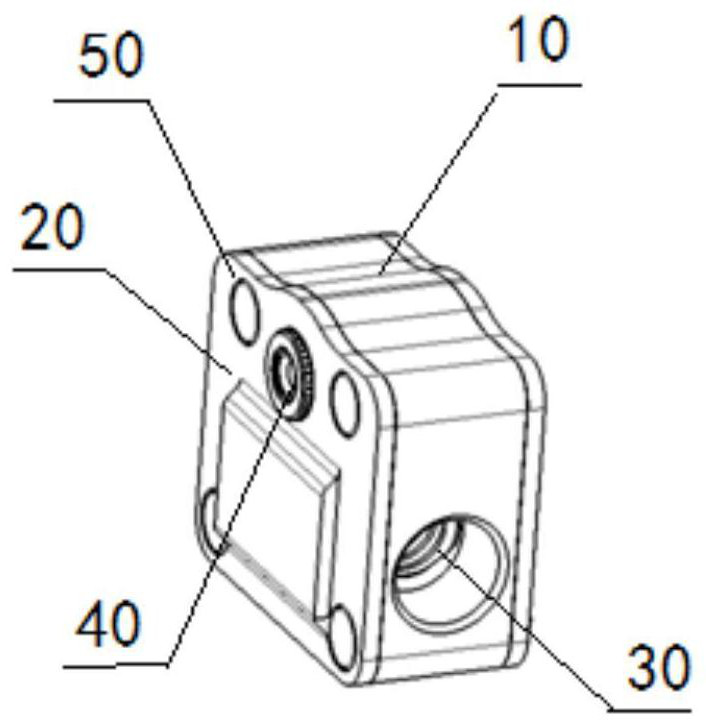

[0016] see image 3 and Figure 4 , a fully enclosed gearbox assembly shown in the figure, including a gearbox body 10 and two gearbox covers 20, and a worm wheel 30 and a worm 40 installed in the gearbox body 10 and the two gearbox covers 20, The worm wheel 30 and the worm 40 mesh with each other.

[0017] The worm wheel 30 has a worm wheel body 31 and positioning plates 32 located at both ends of the worm wheel body 31 in the axial direction, and four positioning protrusions 32 a are symmetrically arranged on each positioning plate 32 . Worm gear teeth 33 are arranged on the outer periphery of the worm gear body 31 , and screw holes 34 are arranged inside.

[0018] The worm 40 meshes with the worm gear teeth 43 on the worm wheel 40 , and a worm shaft 41 is arranged at both ends of the worm 40 in the axial direction.

[0019] The reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com