Modular laser 3d printer

A 3D printer, 3D printing technology, applied in the field of 3D printing, can solve the problems of poor accuracy, speed and stability, unable to guarantee printing accuracy, speed and product stability, time-consuming and labor-intensive, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

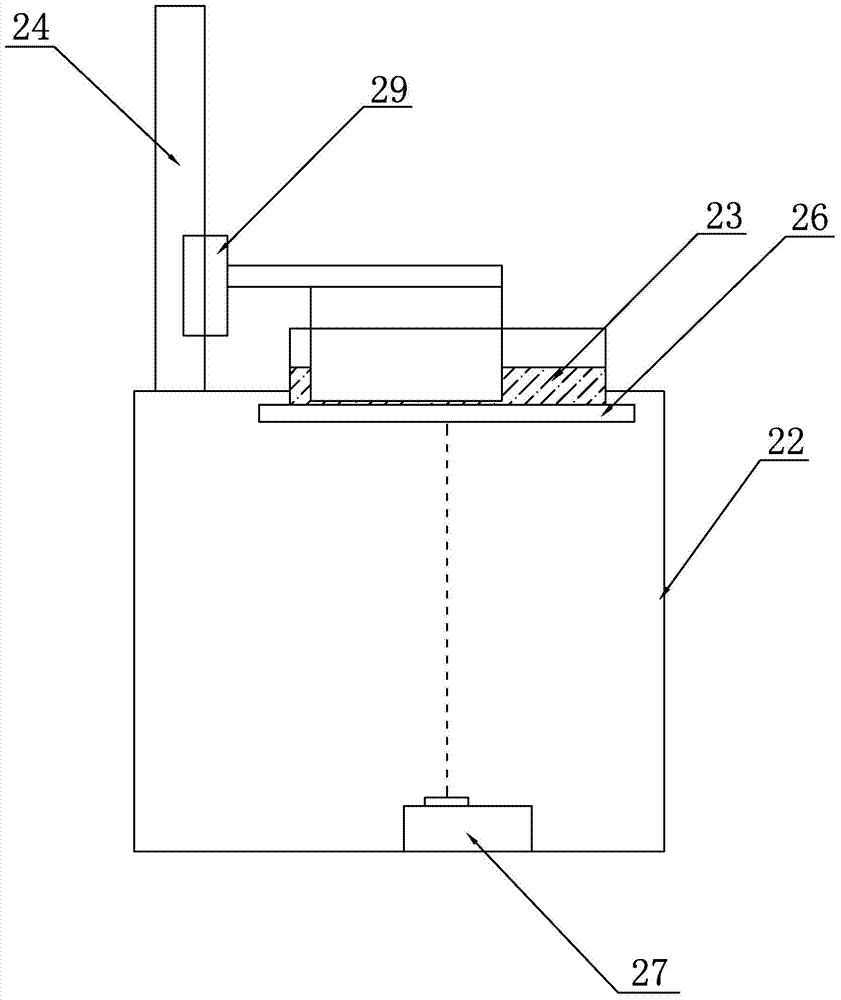

[0024] Such as figure 1 As shown, it is a perspective view of a modular laser 3D printer of the present invention, including a laser 3D printing rapid prototyping module 27, a printer support 22, a resin pool 23, a quartz glass plate 26, a hanging platform 29 and a slide rail 24, and the laser 3D printing rapid prototyping The module 27 is fixed on the middle position of the lower base of the printer support 22 by screws, a quartz glass plate 26 is arranged on the working plane at the top of the printer support 22, a resin pool 23 is placed on the top of the quartz glass plate 26, and the edge position of the printer support 22 top is A slide rail 24 is arranged in the vertical direction, and a suspension platform 29 is installed on the slide rail 24, and the suspension platform 29 can slide up and down along the slide rail 24.

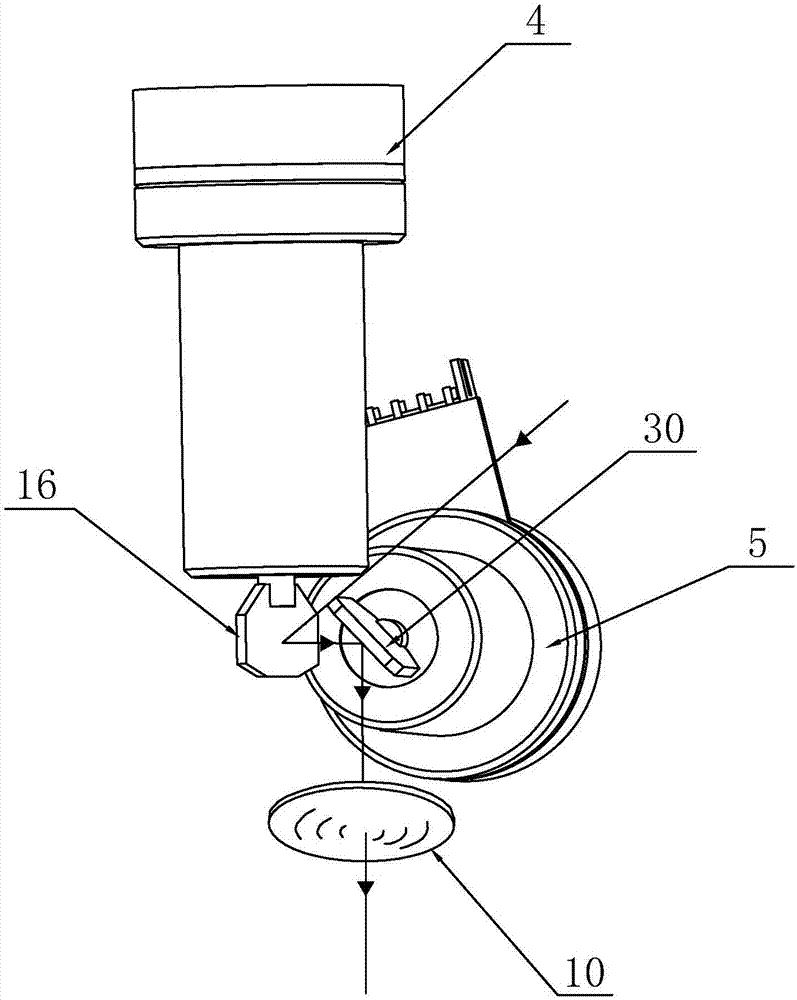

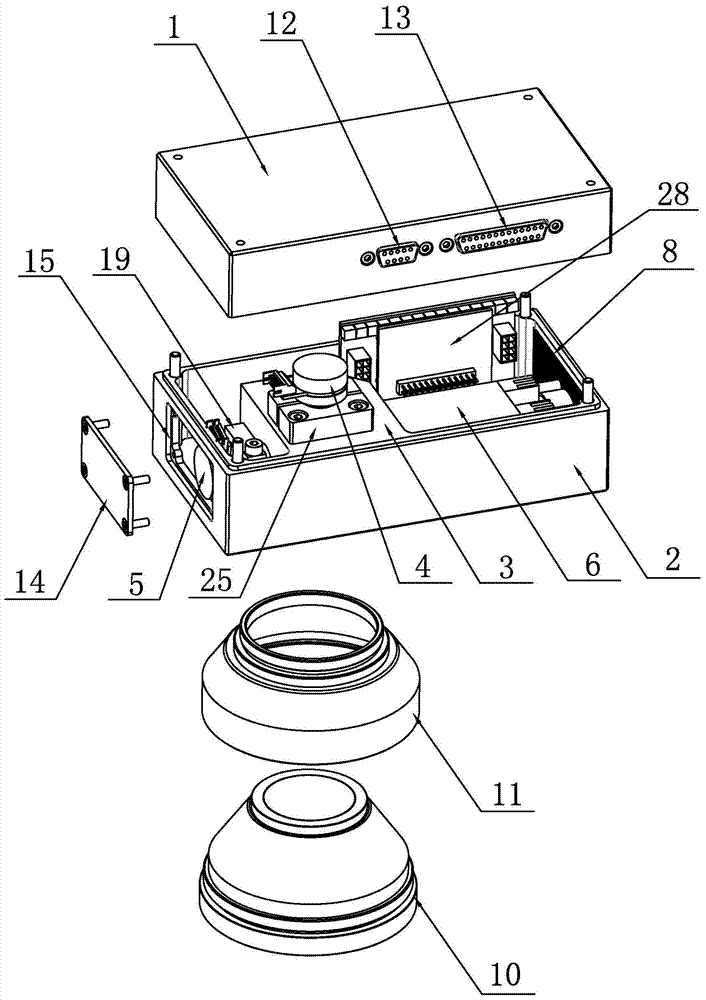

[0025] Such as figure 2 , image 3 As shown, the laser 3D printing rapid prototyping module 27 includes a housing, a laser 6, a field mirror 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com