Assembled disc lock prefabricated panel supporting structure

A technology of prefabricated wall panels and supporting structures, which is applied in building construction, processing of building materials, construction, etc. It can solve the problems of inconvenient access for construction personnel and no consideration of impact during construction, and achieve simple and easy-to-understand installation and disassembly methods. The effect of enhancing the integrity and speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

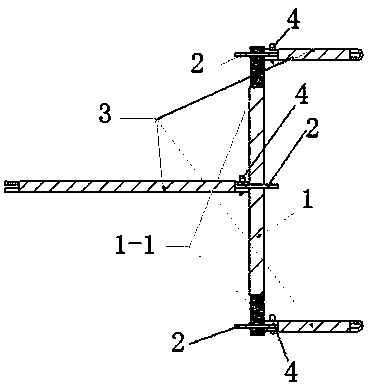

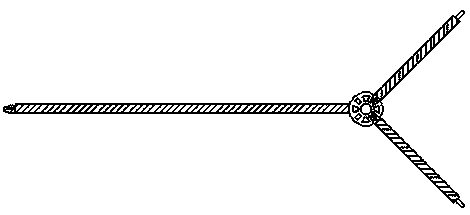

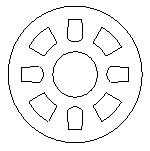

[0024] Such as Figure 1 to Figure 5 As shown, a prefabricated wall panel support structure that can be assembled includes a steel pipe vertical bar 1, a horizontal bar 3, a connecting plate 2, and a latch 4. There are respectively three connection plates 2 on the steel pipe pole 1 (see image 3 ), the upper and lower connection plates 2 are connected with the threaded section 1-1 of the vertical rod through the thread groove; the upper and lower connection plates 2 each have two cross bars 3 connected with the connection plate 2 through the pin 4 (see Figure 4 , Figure 5 ), the connecting plate 2 in the middle is connected to a cross bar 3 through a pin 3 .

[0025] The invention adopts a unified mold to produce, and can be disassembled and spliced repeatedly. The upper and lower cross bars 3 are bolted to the pre-embedded nuts of the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com