Spirally wound electrochemical water treatment reactor

A technology of spiral winding and water treatment, which is applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Frequent flushing time and other problems, to achieve the effect of reducing short flow and dead water area, good stability and replaceability, and eliminating the need for re-filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

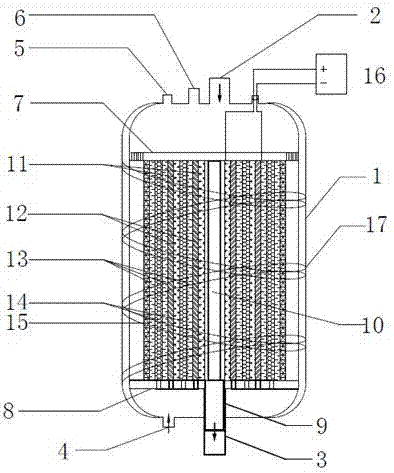

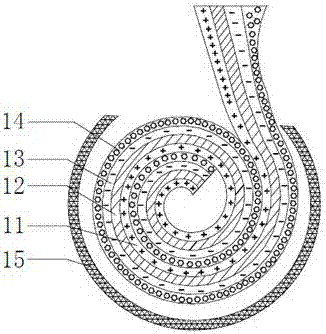

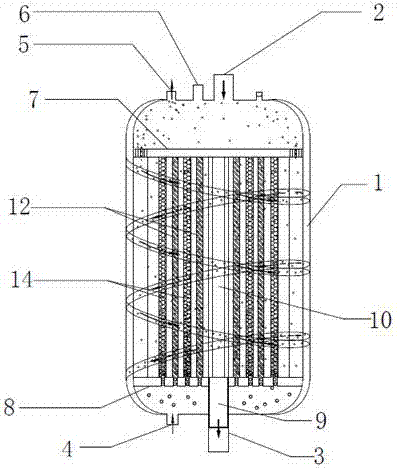

[0042] During specific implementation: if Figure 1 to Figure 5 As shown, a spiral-wound electrochemical water treatment reactor includes a long cylindrical shell 1 arranged vertically. The water outlet 2 and the water outlet 3 are provided with an electrocatalytic oxidation component inside the reaction space of the housing 1, and the electrocatalytic oxidation component separates the reaction space between the water inlet 2 and the water outlet 3, and the electrocatalytic oxidation component includes a spiral The wound anode electrode layer 11 and the cathode electrode layer 13 arranged at intervals from the anode electrode layer 11 and spirally wound outside the anode electrode layer 11, the anode electrode layer 11 and the cathode electrode layer 13 are both mesh structures, The distance between the cathode electrode layer 13 and the anode electrode laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com