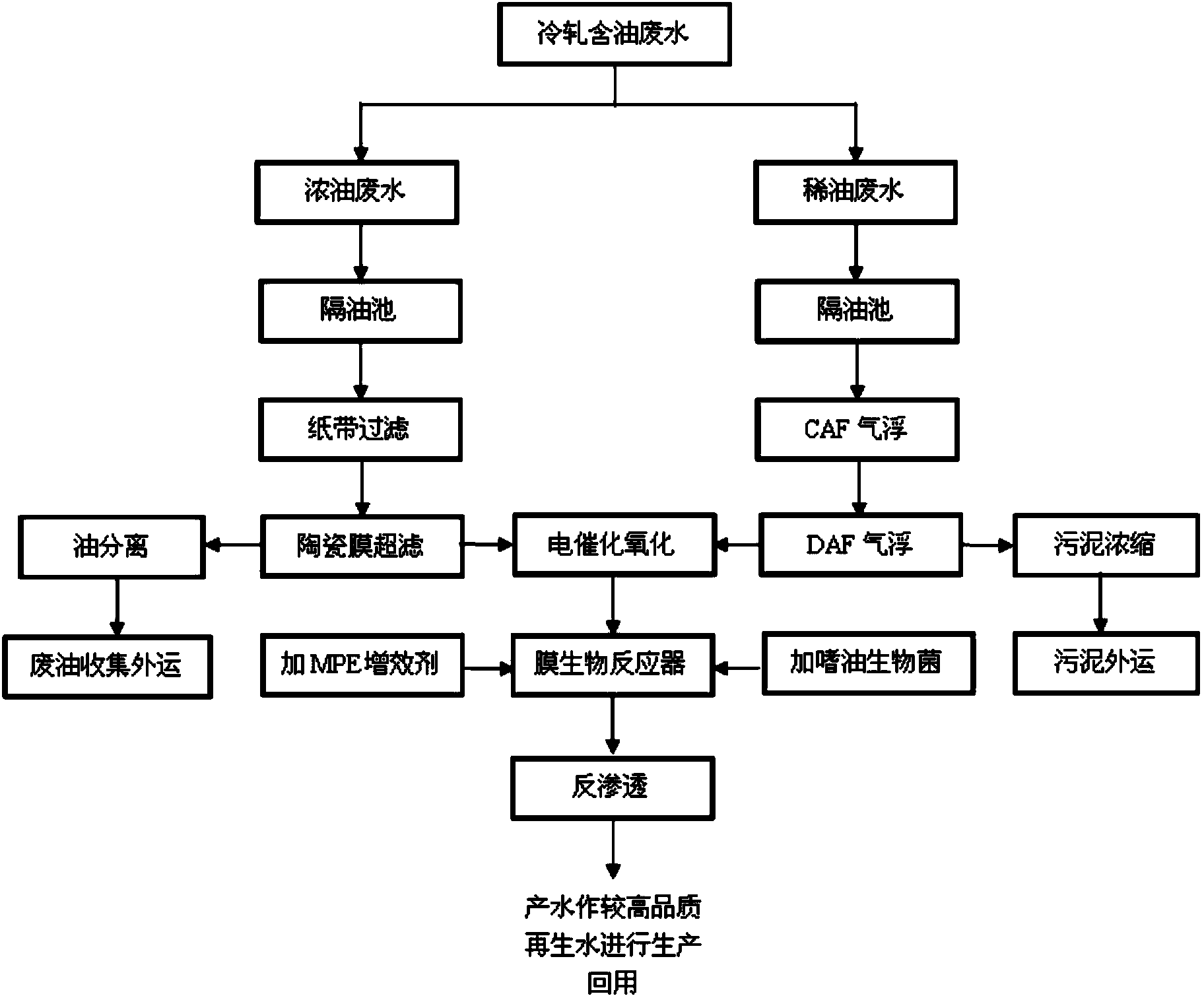

Cold rolling oily wastewater treatment process

A waste water treatment, waste water technology, applied in the direction of metallurgical waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of unstable treatment effect, poor effluent quality, difficult treatment, etc., to achieve Significant economic and environmental benefits, improved wastewater reuse rate, and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 18000mg / L, oil content is 10000mg / L, SS is 5000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , the water quality is as follows: COD is 3000mg / L, oil content is 400mg / L, SS is 3000mg / L.

[0033] The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles...

Embodiment 2

[0043] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 50000mg / L, oil content is 3000mg / L, SS is 1000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , its water quality is as follows: COD is 2000mg / L, oil content is 500mg / L, SS is 500mg / L.

[0044] The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles o...

Embodiment 3

[0055] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 40000mg / L, oil content is 12000mg / L, SS is 8000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , its water quality is as follows: COD is 1000mg / L, oil content is 100mg / L, SS is 4000mg / L.

[0056]The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com