Electroplating chromium-free coarsening chemical solution purifying and recycling system and method

A chemical solution and coarsening technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high cost, environmental pollution, and expensive chromic anhydride, and achieve high reuse rate, reduced operating cost, and stable treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

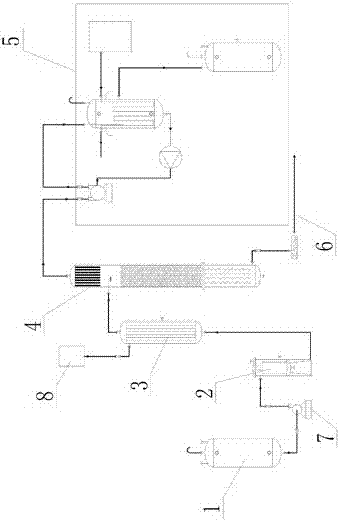

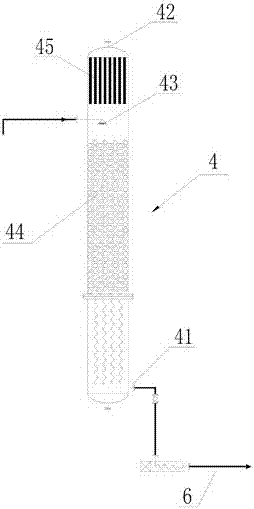

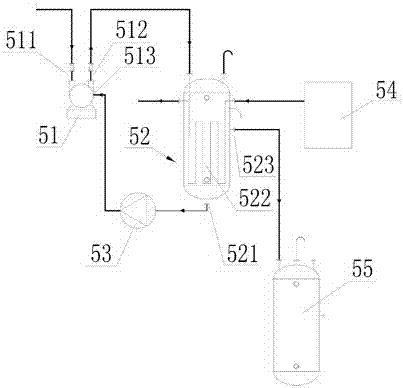

[0021] Attached below figure 1 to attach image 3 , and specific embodiments will further illustrate the present invention.

[0022] like figure 1 As shown, a system and method for purifying and recycling electroplating chrome-free roughening chemical solution, including a mother liquor collection tank 1 for storing chromium-free chemical solution, a precision filter 2 for filtering chromium-free chemical solution, and a Heat exchanger 3 for chromium chemical solution, vacuum dehydration tower 4 for dehydrating chromium-free chemical solution, and vacuum unit 5 for providing negative pressure to vacuum dehydration tower 4 and collecting water vapor generated after dehydration of chromium-free chemical solution The water outlet of the mother liquid collection tank 1 is communicated with the water inlet of the precision filter 2, the water outlet of the precision filter 2 is communicated with the water inlet of the heat exchanger 3, and the water outlet of the heat exchanger 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com