Ammonia nitrogen/total nitrogen treatment device and method

A nitrogen treatment and ammonia nitrogen technology, applied in the field of environmental engineering, can solve the problems of pollution and seriousness, and achieve the effects of high efficiency, fast balance speed and little secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

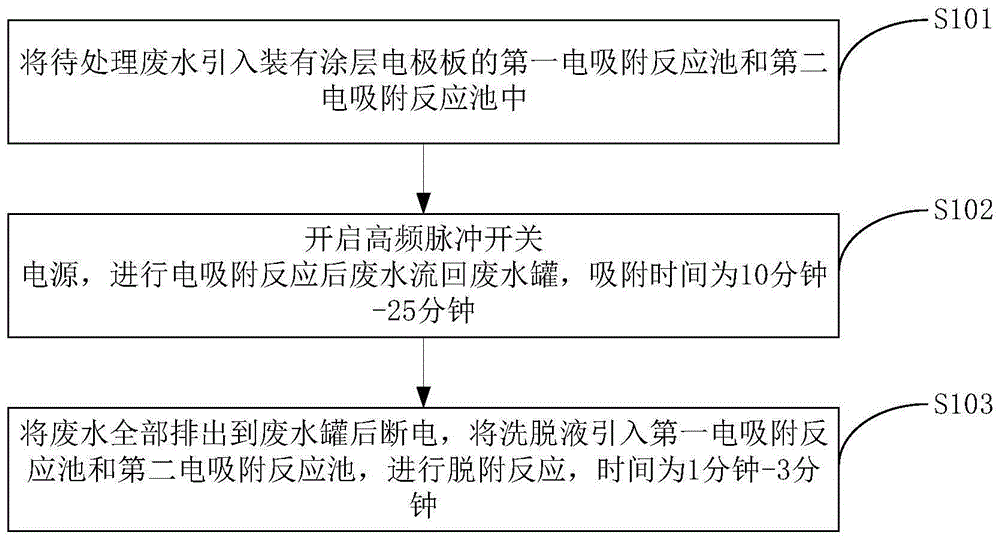

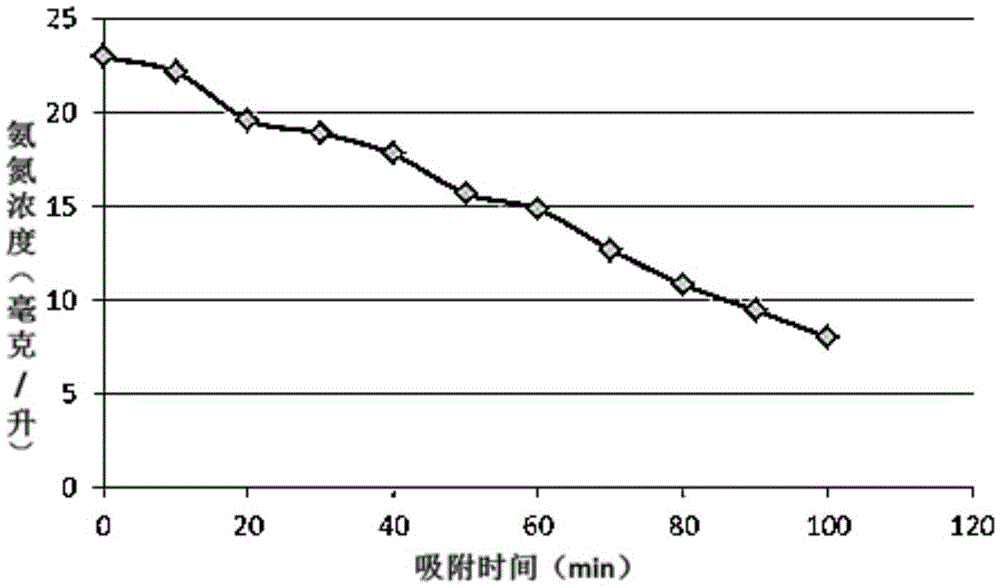

[0025] Attached below Figures 1 to 3 and specific embodiments to further describe the application principle of the present invention.

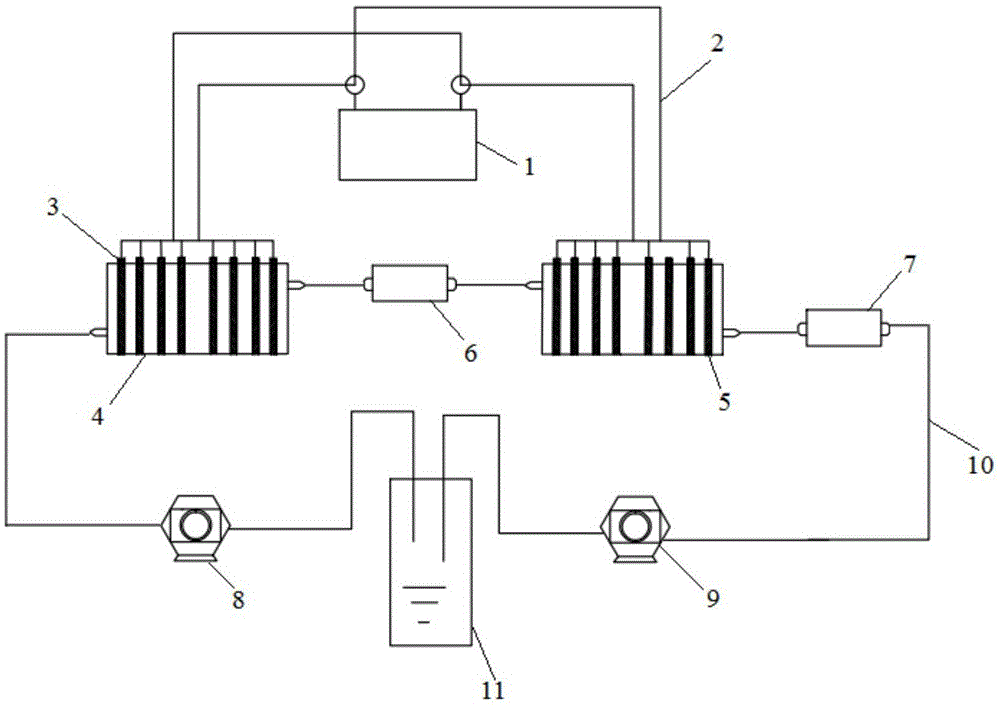

[0026] The ammonia nitrogen and total nitrogen treatment device includes: a high-frequency pulse switching power supply 1, a wire 2, a coated electrode plate 3, a first electrosorption reaction pool 4, a second electrosorption reaction pool 5, a first transition water tank 6, a second transition Water tank 7, first water pump 8, second water pump 9, silicone tube 10, waste water tank 11;

[0027] The power-on method adopted is power-on-power-off-power-on and output square wave pulse dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com