High-concentration ammonia-nitrogen wastewater catalytic oxidation treatment device and treatment method thereof

A technology for catalytic oxidation and ammonia nitrogen wastewater, which is applied in water/sewage treatment, chemical instruments and methods, degassed water/sewage treatment, etc. Wastewater treatment pressure, solving the problem of ammonia nitrogen pollution, and the effect of high ammonia nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the description of the invention, it is to be noted that the term "mount", "connected", "connection", such as a fixed connection, unless otherwise expressly specified and defined, unless otherwise expressly specified and defined. Connect, or integrate; may be mechanical connection, or electrical connection; may be directly connected, or indirectly connected by an intermediate medium, which can be in the interior of the two elements. For those skilled in the art, the specific meaning of the above terms can be understood in the art.

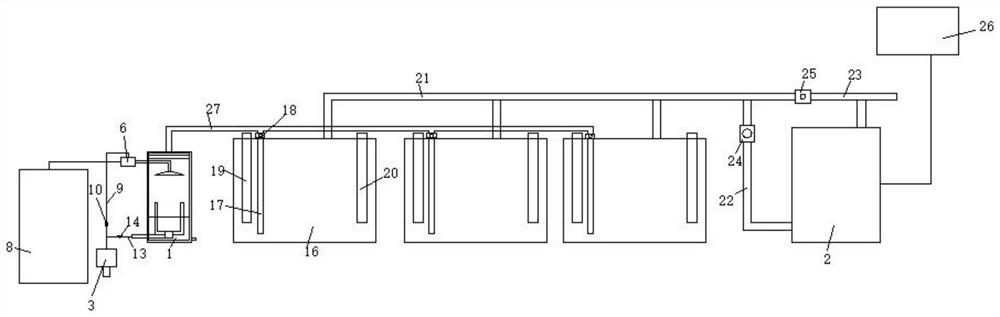

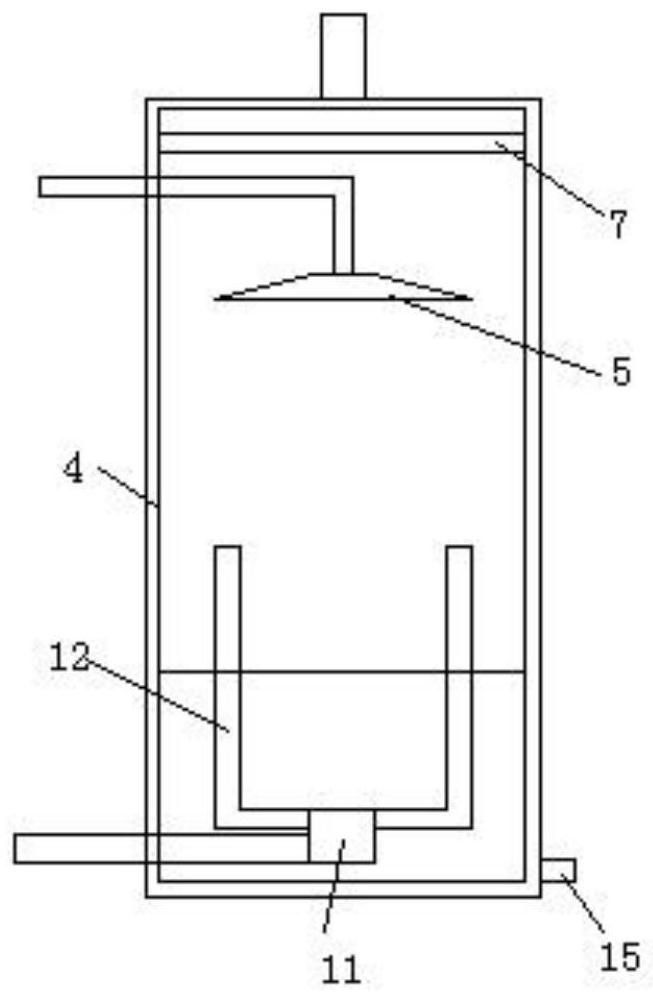

[0023] As shown, high concentration ammonia nitrogen wastewater catalyzed oxidation treatment devices, including blowout devices, several groups of catalytic oxidation devices, adsorption tower, and air pumps;

[0024] The blowout device includes a blowout tank, an atomizing spray head, a gas-liquid mixing pump, a blowing device, the atomizing nozzle disposed above the interior of the blowout, and the atomizing nozzle also has a defective dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com