Nitrating aeration biological filting tank of oyster shell filling

An aerated biological filter and oyster shell technology, which is applied in the field of nitrification aerated biological filter, can solve the problems of low operating cost and high ammonia nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

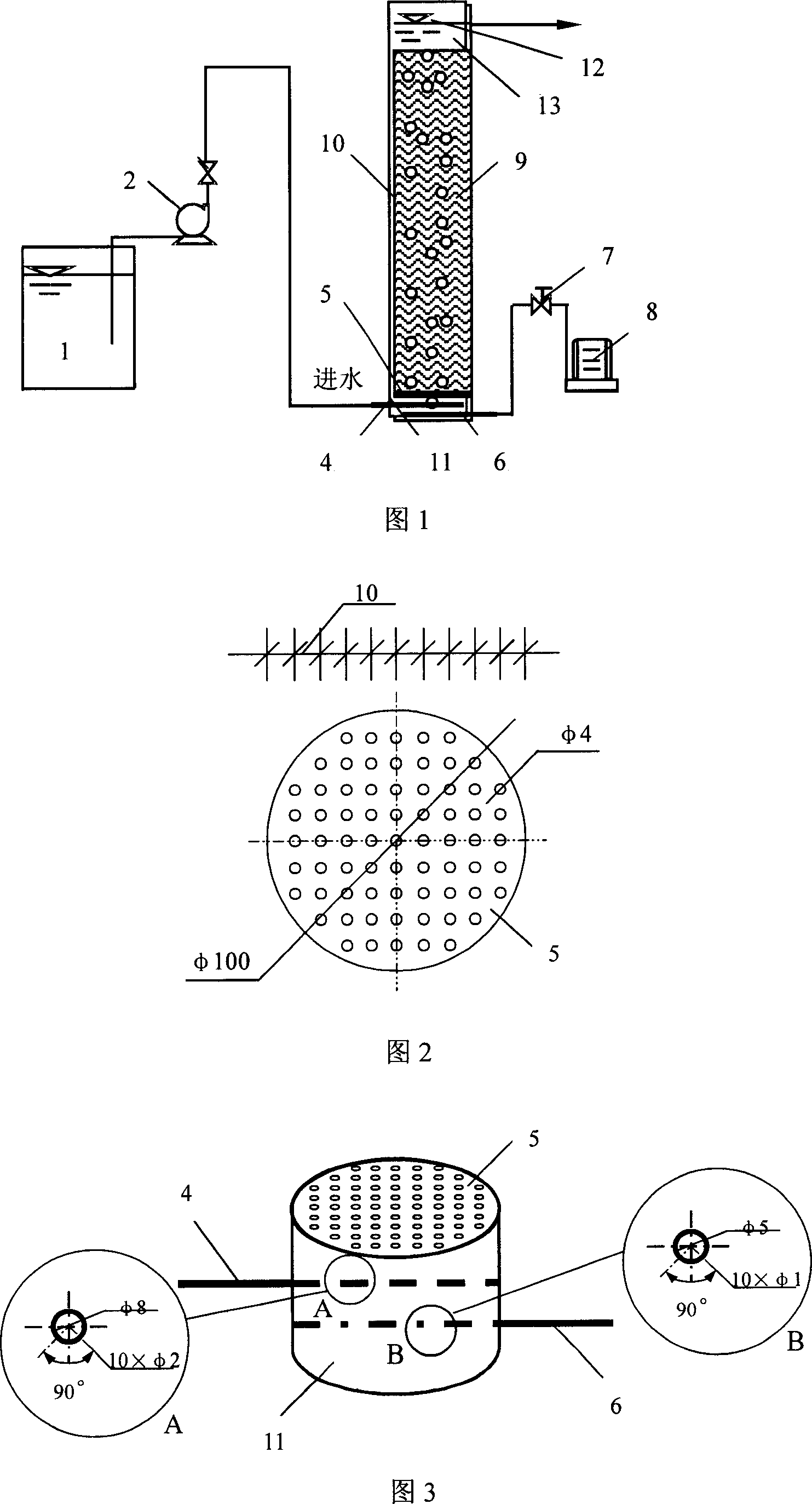

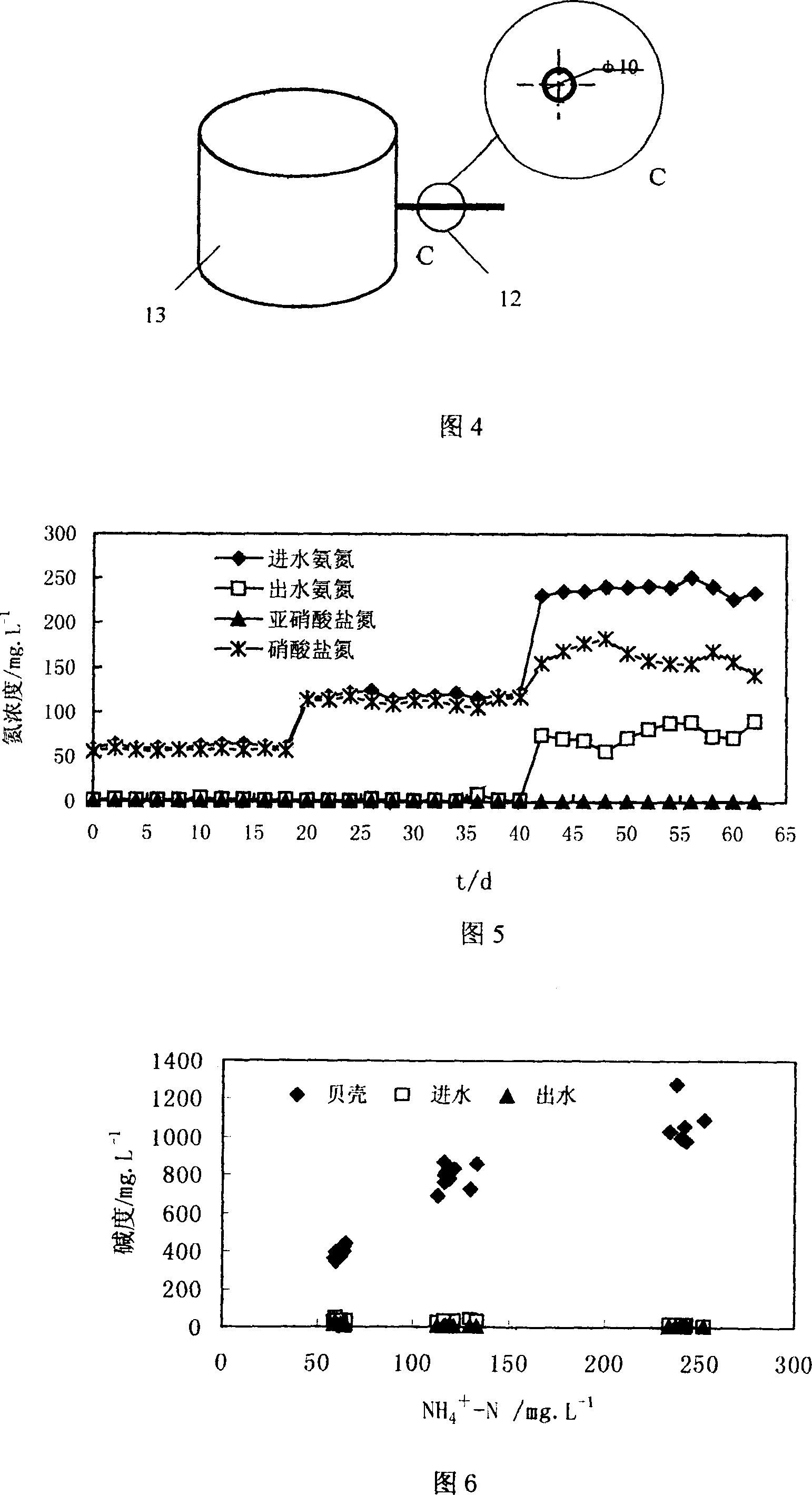

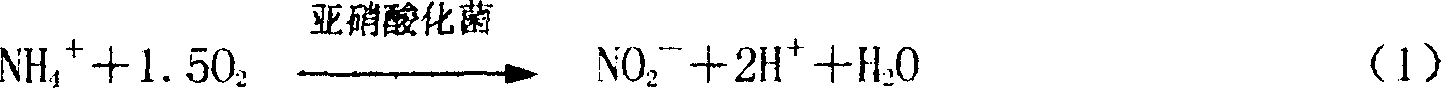

[0022] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

[0023] As shown in Fig. 1-4, the present invention is provided with tank body 10, oyster shell filler 9, support plate 5, water distribution and air distribution device, water outlet and backwash device. The supporting plate 5 is set in the lower part of the pool body 10, and dozens of through holes are set on the supporting plate 5, and the oyster shell filler 9 is filled on the supporting plate 5 in the pool body 10, and the water and air distribution devices are arranged on the supporting plate 5. Below the supporting plate 5, the water and air distribution device is provided with a water distribution pipe 4, an air distribution pipe 6, and a water and air distribution chamber 11, and the water distribution pipe 4 and the air distribution pipe 6 are arranged in the water and air distribution chamber under the supporting plate 5 11; the water distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com