Biogas slurry decarbonization and deamination method and system

A biogas slurry and deamination technology, applied in the field of biogas slurry decarbonization and deamination methods and systems, can solve the problems of human health damage, pollution, waste of resources, etc., and achieve high ammonia nitrogen removal rate, high economic benefits, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

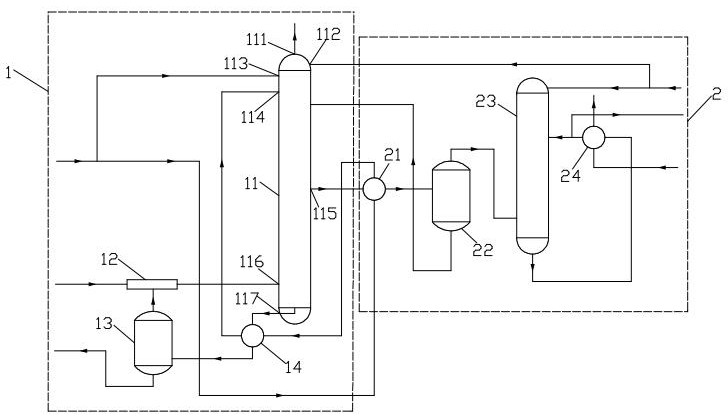

Image

Examples

Embodiment 1

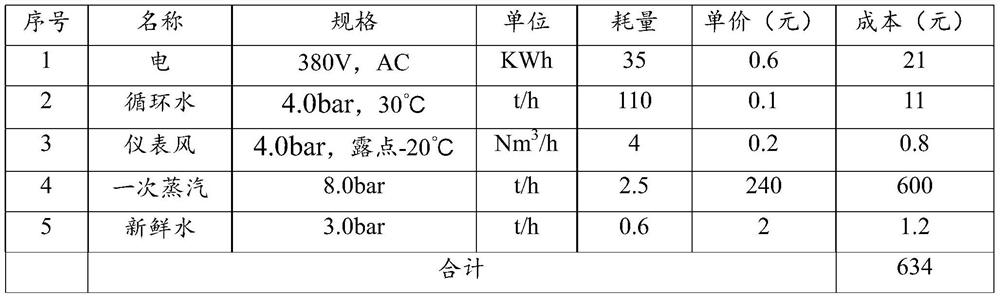

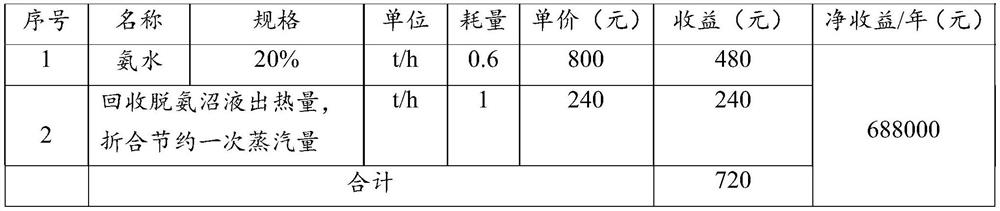

[0074]Input conditions:

[0075] The total feed flow of biogas slurry to be treated is 25t / h, pH: 7.8-9.5; T: 30℃, P: 5.0bar; Composition: NH3-N: 4000-5000mg / L; COD: 5000-6000mg / L; SS: 2000mg / L; CO2: dissolved 5m3 / m3 biogas slurry to be treated.

[0076] The biogas slurry to be treated with a total feed flow of 25t / h is divided into two feeds, one of which passes through the second heat exchanger 21 and the first heat exchanger 14 after heat exchange, and then is input to the hot material inlet 114; the other Input to the cold feed inlet 113; and the flow rate of biogas slurry input to the hot feed inlet 114 accounts for 85% of the total feed flow, and the flow rate of biogas slurry input to the cold feed inlet 113 accounts for 15% of the total feed flow.

[0077] The primary steam is saturated steam: the feed flow rate is 2.5 t / h; P: 8.0 bar, which is input into the ejector 12 .

[0078] Fresh water fed to the spray inlet 112 of the stripper 11: feed flow 0.3 t / h, pH: 7, T:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com