Novel mixed-flow pump

A mixed-flow pump, a new type of technology, applied in the direction of pumps, pump components, and components of pumping devices for elastic fluids, etc., can solve the problems of insignificant use effect and complex structure, improve water inlet conditions, and reduce cavitation. Effects of Noise, Suppression Strength, and Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

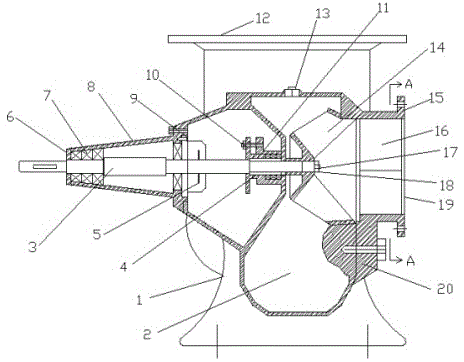

[0012] In order to further understand and recognize the structure, features and effects of the present invention, a preferred embodiment is now given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

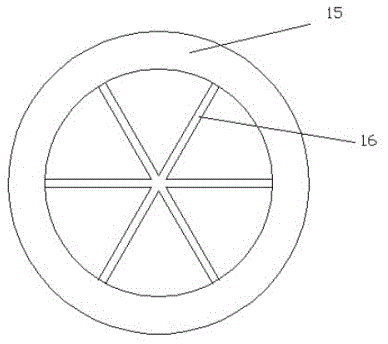

[0013] Such as figure 1 with figure 2 As shown, the novel mixed-flow pump described in this embodiment mainly includes a pump body 1, a pump shaft 3, an impeller 14, and an impeller 16. On one end of the pump shaft 3, the impeller 14 is installed through the pump shaft 3 in the mixed flow chamber 2 composed of the pump body 1 and the pump cover 10. Into an integral structure, the side wall of the pump body 1 is provided with a suction port 19, the upper part of the pump body 1 is provided with a water outlet 12, and the suction port 19, the mixed flow chamber 2 and the water outlet 12 are connected. The left side wall of the pump body 1 is provided with The bearing body 8 fixed with it, the pump shaft 3 extends out of the bearing body 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com