Ecological treatment system and ecological treatment method for gravel yard

A technology of ecological management and sand and gravel materials, which is applied to botany equipment and methods, grain treatment, planting substrates, etc., can solve problems such as poor water storage capacity, excessive sand and gravel, and low nutrients, so as to improve water retention and improve soil Pores, the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

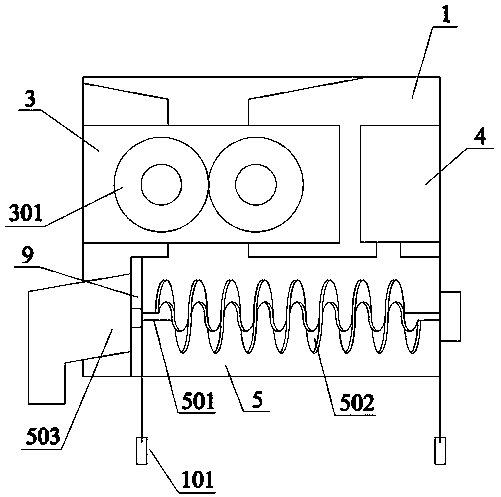

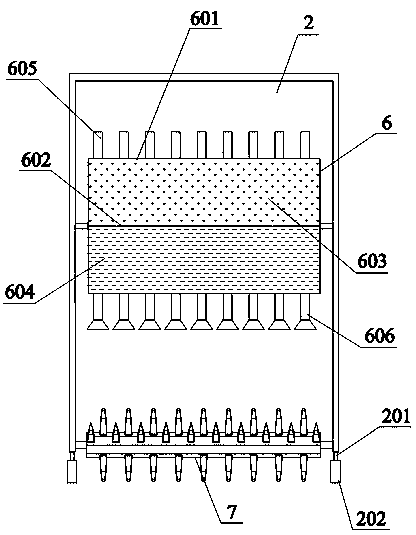

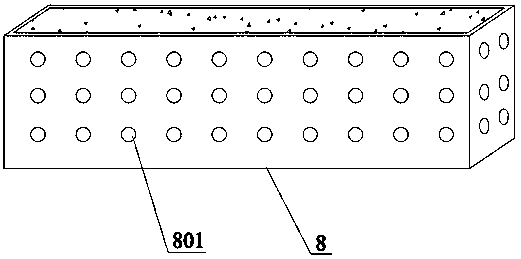

[0034] An ecological governance system for sand and gravel quarries, including a soil treatment module 1 and a planting restoration module 2, such as figure 1 As shown, the soil treatment module 1 includes a crushing chamber 3, an improved matrix chamber 4, and a mixing chamber 5. Two rollers I101 are provided at the bottom of the soil treatment module 1 to facilitate mobile operations on the sand and gravel yard. The crushing chamber 3. Improve the communication between the bottom of the matrix chamber 4 and the top of the mixing chamber 5. The crushing chamber 3 is provided with crushing rollers 301, and the mixing chamber 5 is provided with a horizontal stirring shaft 501 along the central axis. The stirring shaft 501 is provided with a spiral blade 502, the spiral blade 502 is a left-handed blade, the stirring shaft 501 rotates counterclockwise to feed, and the stirring shaft 501 rotates clockwise to discharge; one end of the mixing chamber 5 Be provided with discharge por...

Embodiment 2

[0045] An ecological management system for a sand and gravel quarry, including a soil treatment module 1 and a planting restoration module 2, the soil treatment module 1 includes a crushing chamber 3, a matrix improvement chamber 4 and a mixing chamber 5, and the bottom of the soil treatment module 1 is provided with two A roller I101 is convenient for moving operations on the sand and gravel yard. The bottom of the crushing chamber 3 and the improved matrix chamber 4 communicate with the top of the mixing chamber 5. The crushing chamber 3 is equipped with crushing rollers 301. The mixing A horizontal stirring shaft 501 is provided in the chamber 5 along the central axis, and a helical blade 502 is provided on the agitating shaft 501. The helical blade 502 is a left-handed blade, and the agitating shaft 501 rotates counterclockwise to feed materials. The stirring shaft 501 rotates clockwise to discharge; one end of the mixing chamber 5 is provided with a discharge port 503, and...

Embodiment 3

[0056] An ecological management system for a sand and gravel quarry, including a soil treatment module 1 and a planting restoration module 2, the soil treatment module 1 includes a crushing chamber 3, a matrix improvement chamber 4 and a mixing chamber 5, and the bottom of the soil treatment module 1 is provided with two A roller I101 is convenient for moving operations on the sand and gravel yard. The bottom of the crushing chamber 3 and the improved matrix chamber 4 communicate with the top of the mixing chamber 5. The crushing chamber 3 is equipped with crushing rollers 301. The mixing A horizontal stirring shaft 501 is provided in the chamber 5 along the central axis, and a helical blade 502 is provided on the agitating shaft 501. The helical blade 502 is a left-handed blade, and the agitating shaft 501 rotates counterclockwise to feed materials. The stirring shaft 501 rotates clockwise to discharge; one end of the mixing chamber 5 is provided with a discharge port 503, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com