Deep treatment method of petrochemical engineering organic wastewater difficult to biodegrade

A refractory biodegradable and petrochemical technology, applied in the field of chemical sewage treatment, can solve the problems of complex components, high chemical oxygen consumption, high toxicity, etc., and achieve significant improvement, increase reaction efficiency, reduce ozone depletion and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

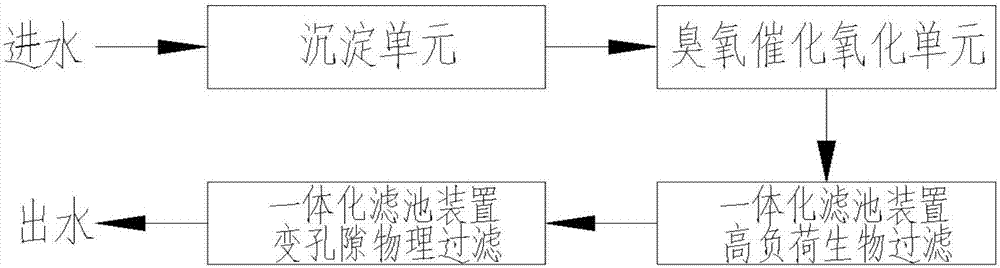

Method used

Image

Examples

Embodiment

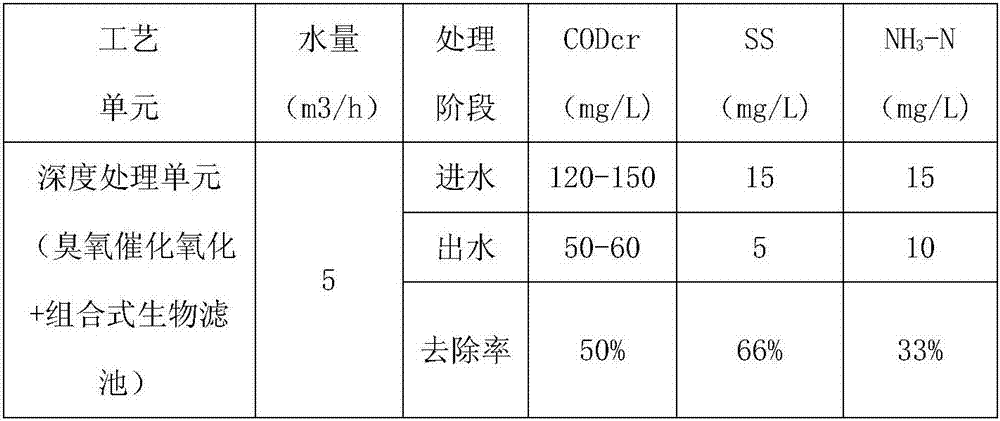

[0029] When a petrochemical sewage treatment plant in Wuhai adopts the existing secondary treatment process, the chemical oxygen demand (COD) of the secondary treatment effluent is high, which cannot meet the national discharge standards, has poor biodegradability, high chroma, complex components, and large water quality changes . Therefore, the combination process of ozone catalytic oxidation and integrated biological filter proposed by the present invention is used to treat the secondary treatment effluent of the sewage treatment plant. The pilot-scale treatment system of this process adopts a system composed of an ozone catalytic oxidation reactor and an integrated biological filter in sequence, wherein the ozone catalytic oxidation reactor is filled with a fixed bed packing as a catalyst, and the volume of the packing accounts for 5% of the volume of the ozone catalytic oxidation reactor , divided into four pieces of modular loading, and the integrated biological filter is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com