Method and device for multicomponent oxide pretreatment of organic electroplating waste water

A pretreatment technology for electroplating wastewater, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problem of excessive CODcr in effluent, poor coagulation sedimentation or air flotation pretreatment effect, biochemical bacteria Can not be cultivated and other problems, to achieve the effect of stable operation, improved biochemical performance, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

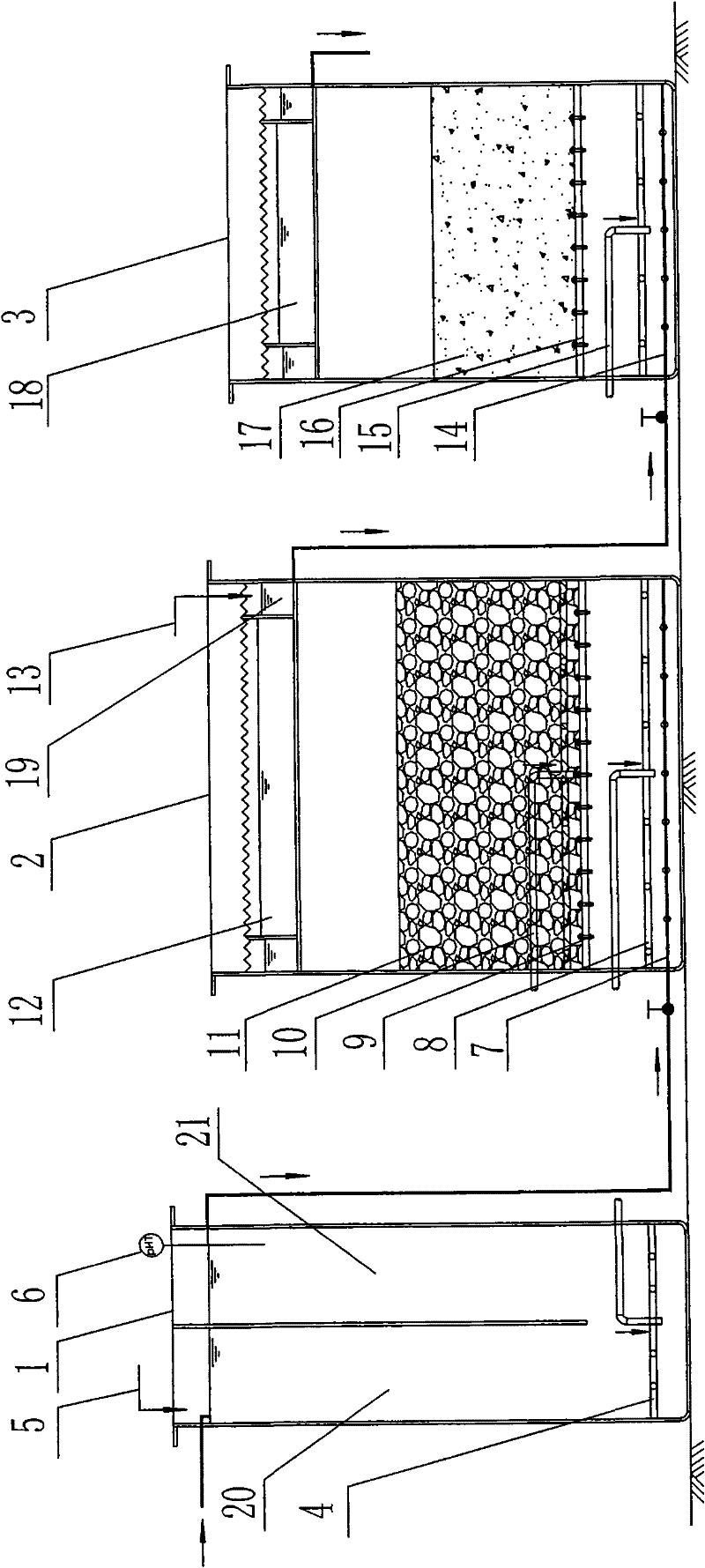

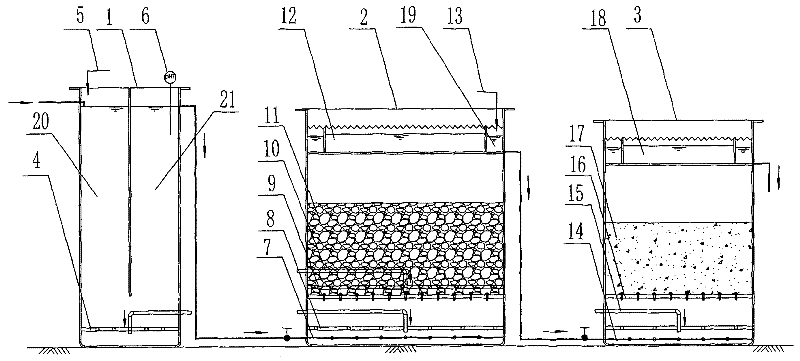

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

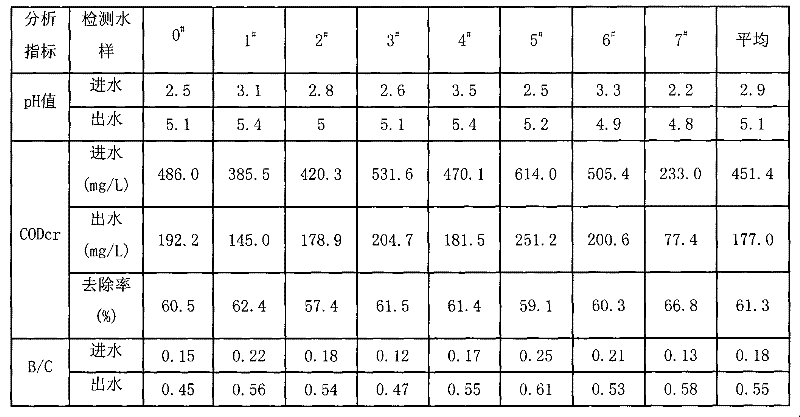

[0021]Organic electroplating wastewater multi-oxidation pretreatment method, organic electroplating wastewater undergoes acidity adjustment, iron-carbon micro-electrolysis reaction, Fenton oxidation reaction in sequence, and then effluent, creating good water inflow conditions for subsequent coagulation sedimentation or air flotation and biochemical treatment. The acidity adjustment controls the pH value of the organic electroplating wastewater to 2.0-5.0 to ensure the acidity conditions required for the iron-carbon micro-electrolysis reaction. Generally, the influent pH value of the organic electroplating wastewater is between 2.0-5.0, and no additional acid is needed Or alkali, using waste to treat waste can save a lot of pharmaceutical costs. The iron-carbon micro-electrolysis reaction is that the organic electroplating wastewater undergoes a micro-electrolysis reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com