Method for processing high-concentration wastewater containing alkaline mud

A technology of alkali residue wastewater and treatment method, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large system impact load, poor biodegradability, and high power consumption , to reduce organic matter load, improve biodegradability, and reduce COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

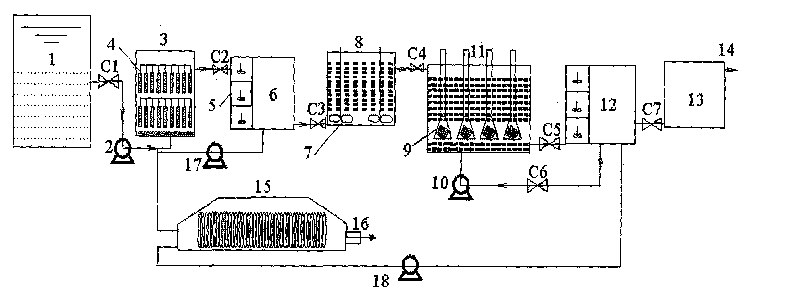

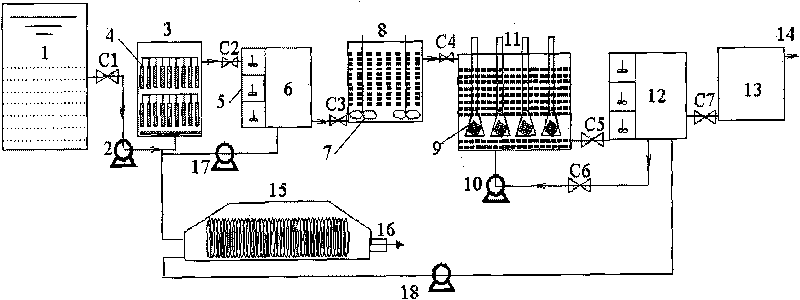

[0038] Such as figure 1 As shown, the alkali slag wastewater enters the regulating tank 1 to adjust the water volume and water quality, and enters the micro-electrolysis pretreatment system 3 through the lift pump 2 (corrosion-resistant treatment), and enters the water from the bottom. The bottom of the micro-electrolysis pretreatment system is equipped with an aeration tube, which has the dual functions of sufficient mass transfer and preventing packing structure. The micro-electrolytic filler is constructed into a rod shape and filled according to a volume ratio of 30%-80%. The stable operation of the micro-electrolysis pretreatment system is ensured by the double structure of water distribution and aeration. The residence time of the whole micro-electrolysis pretreatment process is 2-8h, and it is recommended to be 4-6h, so as to ensure the effect of pretreatment. The pretreatment system enters the coagulation sedimentation system through the valve C2. The coagulation mixi...

Embodiment 2

[0041] Take the comprehensive alkali slag effluent from a petrochemical refinery through mild wet oxidation technology. The characteristics of the wastewater are high organic matter, high toxicity, high phenolic substances, and poor biodegradability. The COD concentration is 81000mg / L, the volatile phenol content is 910mg / L, and the BOD / COD is less than 0.05, and the chromaticity is 12500 times.

[0042] The micro-electrolysis pretreatment reactor uses iron-carbon mixture as the filler layer, and the filling rate is 20%. The temperature of the reactor is controlled at room temperature. When the residence time of alkali slag wastewater is 8-12h, the COD concentration of the effluent is 6000mg / L, BOD / COD =0.34, the volatile phenol concentration is 76mg / L, the whole effluent has the taste of yogurt, the pungent taste basically disappears, and the chroma is reduced to about 800 times. The effluent of the micro-electrolysis system is treated by the coagulation system, and the COD ...

Embodiment 3

[0046] After mild wet oxidation treatment in a petrochemical refinery, the alkali slag wastewater stored in the storage tank is mixed with the upper concentrated liquid and the small layer clear liquid at a ratio of 1:3. The mixed COD concentration is 300,000 mg / L and the chromaticity is 50,000 times . The iron-carbon and iron-copper systems are used for treatment respectively. When the hydraulic retention time is 6h, the COD concentration after treatment by the iron-carbon system is 16984mg / L, the chromaticity of the effluent is 1200 times, and the COD concentration after treatment by the iron-copper system is 19864mg / L, the chromaticity of the effluent is 900 times, the biodegradability BOD / COD of the wastewater after iron-carbon and iron-copper treatment are 0.43 and 0.52 respectively, and the biodegradability of the wastewater is greatly improved. The effluent of iron-copper micro-electrolysis is coagulated and precipitated, and a polymer flocculant with a molecular weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com