Oil-bearing car-washing wastewater treatment method and equipment

A technology for wastewater treatment and car washing wastewater, which is applied in the direction of vehicle washing facility wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve problems such as unstable effluent quality, large equipment footprint, and small processing capacity. , to achieve enhanced clarification effect, low operating cost, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

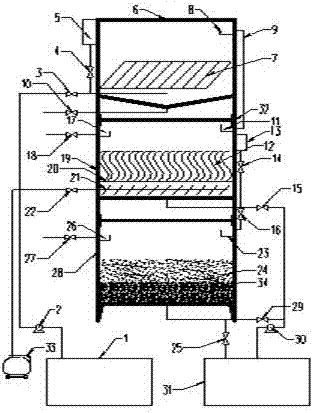

[0048] Equipment wastewater treatment and backwashing methods and processes:

[0049] 1. Equipment wastewater treatment method and process:

[0050] After the initial settlement of the waste water in the open channel, it flows into the waste water collection tank 1 located underground after being coarsely filtered by the grid, starts the waste water lifting pump 2, opens the waste water inlet valve 3, and the coagulant dosing valve 4, and the waste water and the coagulant After mixing, it enters the coagulation sedimentation tank 6, the coagulation water settles through the inclined plate 7, and the upper clarified liquid flows into the filter tank 11 through the overflow tank 8 through the artesian pipe 9, and then enters the fiber filter tank 19.

[0051] The clarified water is filtered in the fiber bundle filter material 12, and then flows into the adsorption box water inlet tank through the opened filter box clear water outlet valve 16 through the orifice plate 20, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com