Impurity removing method in process of preparing alumina from fly ash by utilizing acid method

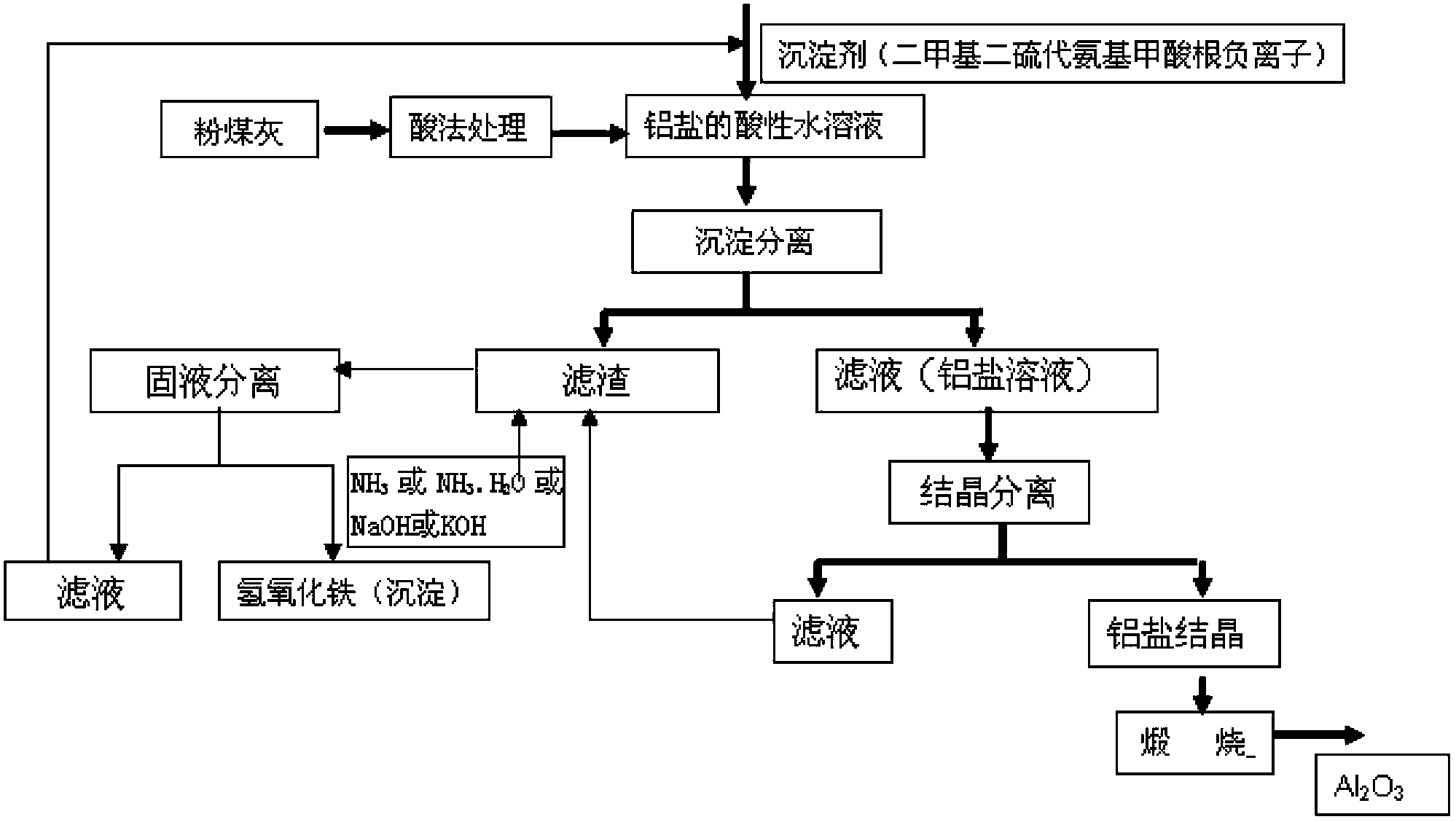

A technology for alumina and fly ash, applied in the field of impurity removal, can solve the problems of difficult separation of impurity iron, complicated alumina process, etc., and achieve the effects of large slag particles and easy removal, remarkable iron removal effect and fast precipitation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) At room temperature, the precipitant (sodium dimethyldithiocarbamate) is pressed by Fe 3+ :Na + The molar ratio is 1:2, and it is added to the acidic aqueous solution of aluminum salt in the process of producing alumina from acid-process fly ash under stirring. The reaction produces black precipitate (ferric dimethyl dithiocarbamate), which is separated by filtration to obtain iron-removed Aluminum salt solution.

[0049] 2) The aluminum salt solution after iron removal is crystallized and separated by filtration to obtain aluminum salt crystals.

[0050] 3) Roasting crystalline aluminum salt to produce alumina.

[0051] 4) Add the black precipitate iron dimethyl dithiocarbamate obtained in step 1) to the solution after the aluminum salt crystallization in step 2), add sodium hydroxide, adjust the pH value to 10, and generate a red precipitate (hydrogen iron oxide), separated by filtration to obtain a filtrate containing sodium dimethyldithiocarbamate, which is us...

Embodiment 2

[0053] 1) At room temperature, the precipitant (potassium dimethyldithiocarbamate) was 3+ : K + The molar mass ratio is 1:4, and it is added to the acidic aqueous solution of aluminum salt in the process of producing alumina from acid-process fly ash under stirring. The reaction produces black precipitate (ferric dimethyl dithiocarbamate), which is separated by filtration to obtain iron removal After aluminum salt solution.

[0054] 2) The aluminum salt solution after iron removal is crystallized and separated by filtration to obtain aluminum salt crystals.

[0055] 3) Roasting crystalline aluminum salt to produce alumina.

[0056] 4) Add the black precipitate (ferric dimethyl dithiocarbamate) obtained in step 1) to the solution after the aluminum salt crystallization and precipitation in step 2, and add potassium hydroxide to adjust the pH value to 13, and generate a red precipitate (hydrogen iron oxide), separated by filtration to obtain a filtrate containing potassium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com