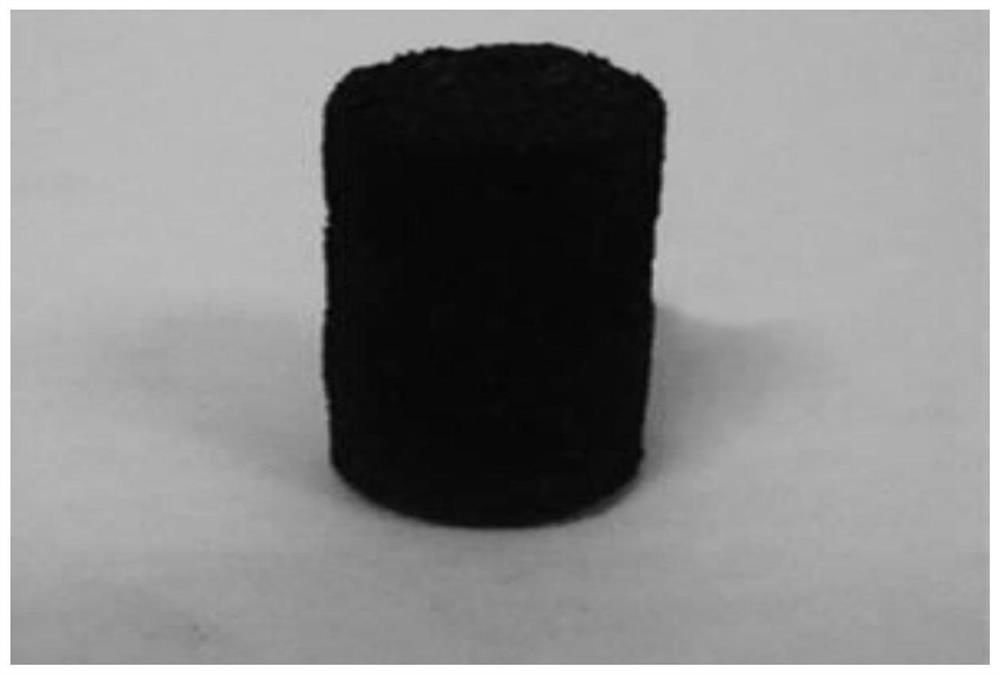

A kind of preparation method of graphene/silver nanowire composite airgel

A composite airgel and silver nanowire technology, applied in the field of nanomaterials, can solve problems such as low mechanical strength and electrical conductivity, irregular spatial arrangement of graphene sheets, complex template removal process, etc., to achieve enhanced electrical conductivity, Environmentally friendly and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 1.0g of metallic sodium and 20mL of o-xylene solvent into a glass container, heat until the temperature reaches 100°C, and the metallic sodium turns into bright yellow sodium balls;

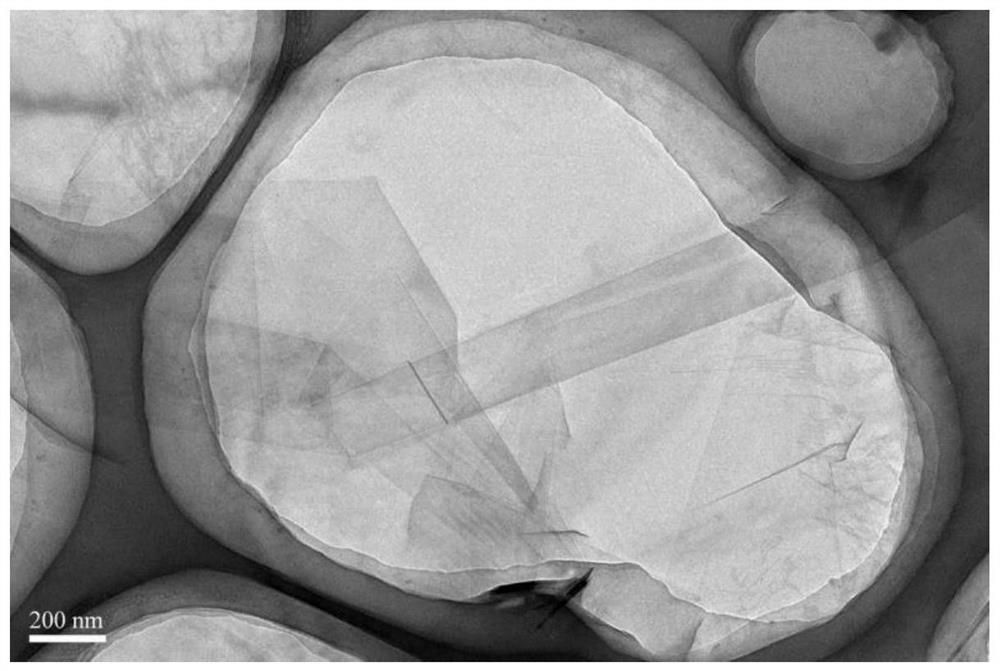

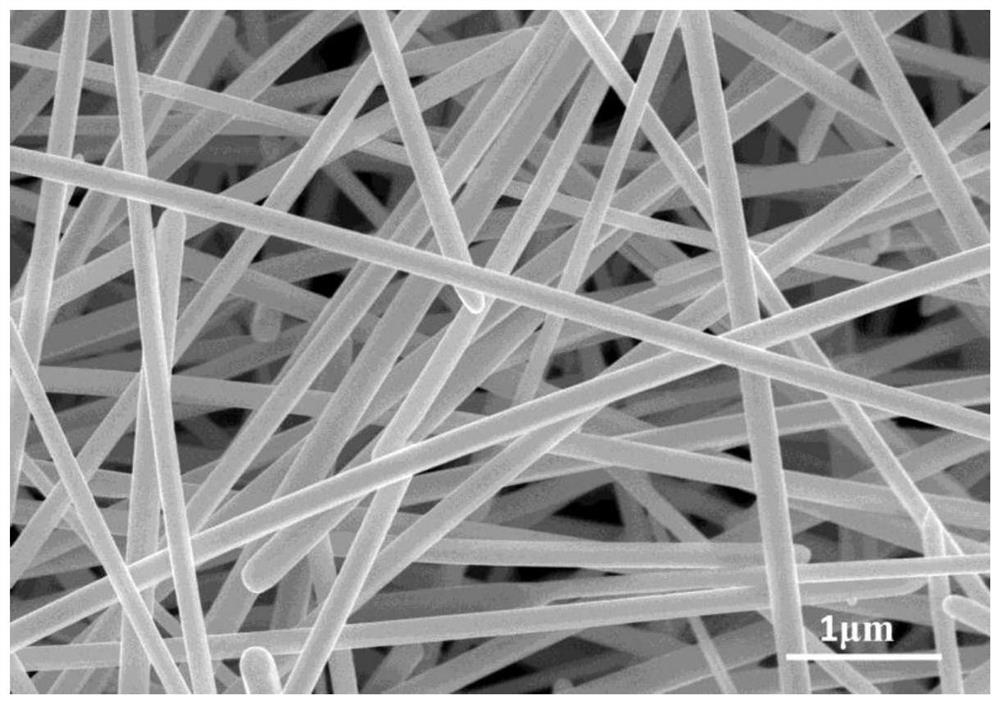

[0030] (2) 10mL concentration is the graphene oxide solution of 10mg / mL and the silver nanowire dispersion liquid that 10mL concentration is 0.4mg / mL obtains the mixed dispersion liquid of graphene oxide-silver nanowire after mixing under ultrasonic;

[0031] (3) In the graphene oxide-silver nanowire mixed dispersion liquid that step (2) obtains, add the polyacrylate particle that 0.2g particle diameter is 20~100nm, form graphene oxide, silver nanowire and template particle after stirring Colloidal mixture;

[0032] (4) 0.2g sodium silicate cross-linking agent is added in the colloidal mixed solution that step (3) obtains and mixes uniformly, then add dropwise in the system that step (1) forms, due to density difference, aqueous phase graphene oxide, silver Nanowires and polyacryl...

Embodiment 2

[0040] (1) Add 5.0g of metallic sodium and 30mL of vegetable oil into a glass container, heat until the temperature reaches 120°C, and the metallic sodium turns into bright yellow sodium balls;

[0041] (2) 10mL concentration is the graphene oxide solution of 20mg / mL and the silver nanowire dispersion liquid that 10mL concentration is 1mg / mL is mixed under ultrasonic to obtain the mixed dispersion liquid of graphene oxide-silver nanowire;

[0042] (3) Add 1.0 g of polylactic acid particles to the graphene oxide-silver nanowire mixed dispersion obtained in step (2), with a particle size of 20 to 100 nm, and form a colloid of graphene oxide, silver nanowires and template particles after stirring mixed solution;

[0043] (4) Add 1.0g of silica cross-linking agent into the colloidal mixture obtained in step (3) and mix evenly, then add dropwise in the system formed in step (1), due to density difference, water phase graphene oxide, silver The nanowires and polylactic acid particl...

Embodiment 3

[0050] (1) Add 3.0g of metallic sodium and 50mL of diethyl ether solvent into a glass container, heat until the temperature reaches 80°C, and the metallic sodium turns into bright yellow sodium balls;

[0051] (2) 10mL concentration is the graphene oxide solution of 15mg / mL and the silver nanowire dispersion liquid that 10mL concentration is 0.5mg / mL obtains the mixed dispersion liquid of graphene oxide-silver nanowire after ultrasonic mixing;

[0052] (3) Add 0.5g polyacrylamide particles in the graphene oxide-silver nanowire mixed dispersion liquid that step (2) obtains, particle diameter is 20~100nm, forms graphene oxide, silver nanowire and template particle after stirring Colloidal mixture;

[0053] (4) Add 0.5g sodium titanate cross-linking agent to the colloidal mixture obtained in step (3) and mix evenly, then add dropwise in the system formed in step (1), due to the difference in density, the aqueous phase graphene oxide, silver Nanowires and polyacrylamide particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com