Magnetic filtering process and device for removing alkyl pollutants in waste water

A technology of magnetic filtration and pollutants, which is applied in the direction of water pollutants, filtration treatment, water/sewage treatment, etc., can solve the problems of high cost of activated carbon and inability to recycle, so as to solve the difficulty of removal, increase the efficient removal effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

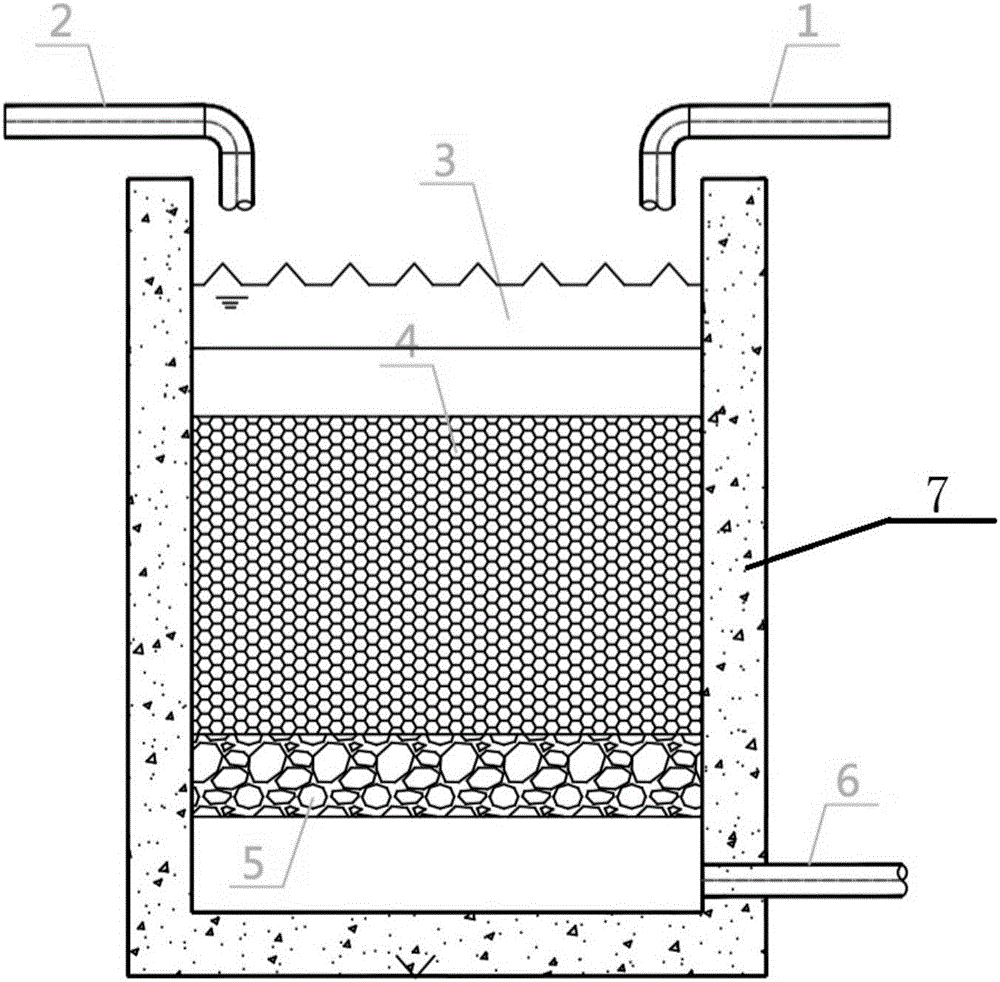

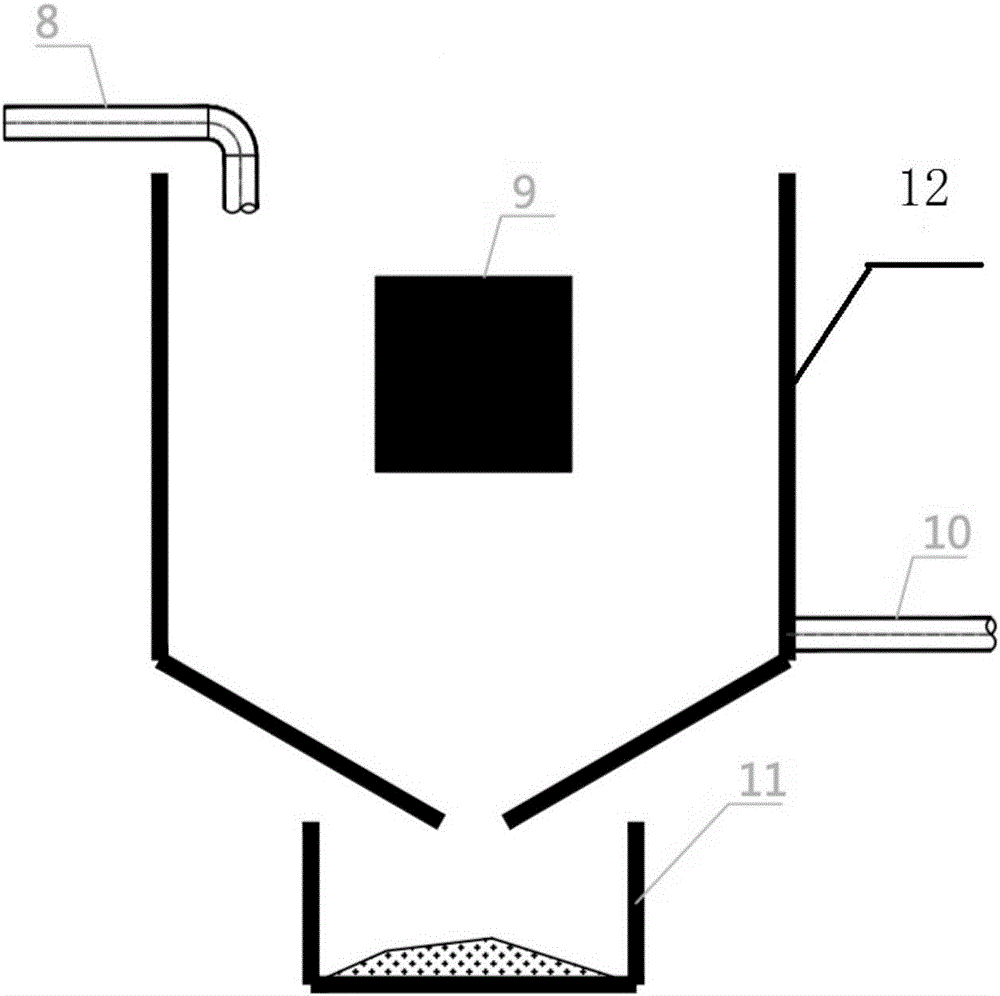

[0033] A magnetic filtration process for removing hydrocarbon-based pollutants in wastewater, including the steps of magnetic filtration, backwashing, magnetic powder recovery, and high-temperature catalytic regeneration; the specific process is:

[0034] 1) Magnetic filtration: a. Add 30 g of decane to 200 ml of distilled water and stir, adjust the pH to 3.5 with hydrochloric acid, then place 100 ml of the obtained water sample in beaker A, and put the other half in beaker B, respectively as Wastewater sample A and wastewater sample B;

[0035] b. Use the preloading method to fix the magnetic powder into the homogeneous filter material layer of the magnetic filter device (the particle size of the homogeneous filter material is 3mm). The specific method is: add tap water mixed with magnetic powder into the water inlet pool, Add 0.01g of magnetic powder per 1L of tap water for pre-fixation, and then control the feeding speed to 5m 3 / h, fix the magnetic powder in the homogeneo...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is:

[0043] 1) Magnetic filtration:

[0044] a. The pH of the wastewater is pre-adjusted to 3.0;

[0045] b. The particle size of the homogeneous filter material is 2mm; add tap water mixed with magnetic powder into the water inlet pool, and add 0.012g of magnetic powder per 1L of tap water for pre-fixation, and then control the feeding speed to 4m 3 / h, fix the magnetic powder in the homogeneous filter material layer;

[0046] c. Use the magnetic powder dosing tube to add 2g of magnetic powder and 100mL of waste water to mix in the suspension tank, and then flow into the homogeneous filter material layer pre-loaded with magnetic powder from the suspension tank for filtration, with a filtration rate of 9m / h;

[0047] 2) Backwashing: water flushing intensity 6L / s.m 2 , air impact strength 14L / s.m 2 , Backwashing time: single air flushing 3min, air-water combined backflushing 3min, separate water flushing 3min; ...

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is:

[0052] 1) Magnetic filtration:

[0053] a. The pH of the wastewater is pre-adjusted to 4.0;

[0054] b. The particle size of the homogeneous filter material is 3mm; add tap water mixed with magnetic powder into the water inlet pool, add 0.015g of magnetic powder per 1L of tap water for pre-fixation, and then control the feeding speed to 6m 3 / h, fix the magnetic powder in the homogeneous filter material layer;

[0055] c. Use the magnetic powder dosing tube to add 3g of magnetic powder and 100mL of waste water to mix in the suspension tank, and then flow into the homogeneous filter material layer pre-loaded with magnetic powder from the suspension tank for filtration. The filtration rate is 12m / h;

[0056] 2) Backwash: water flushing intensity 7L / s.m 2 , air impact intensity 15L / s.m 2 , Backwashing time: single air flushing 4min, combined air-water backflushing 4min, single water flushing 3min; flushing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com