Composite regenerating device and method of complexing iron catalyst for natural gas desulphurization

A composite regeneration and iron complexing technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem that it is difficult to meet the requirements of rapid regeneration of catalysts, etc. Achieve the effect of improving catalyst oxidation regeneration efficiency and reducing device scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

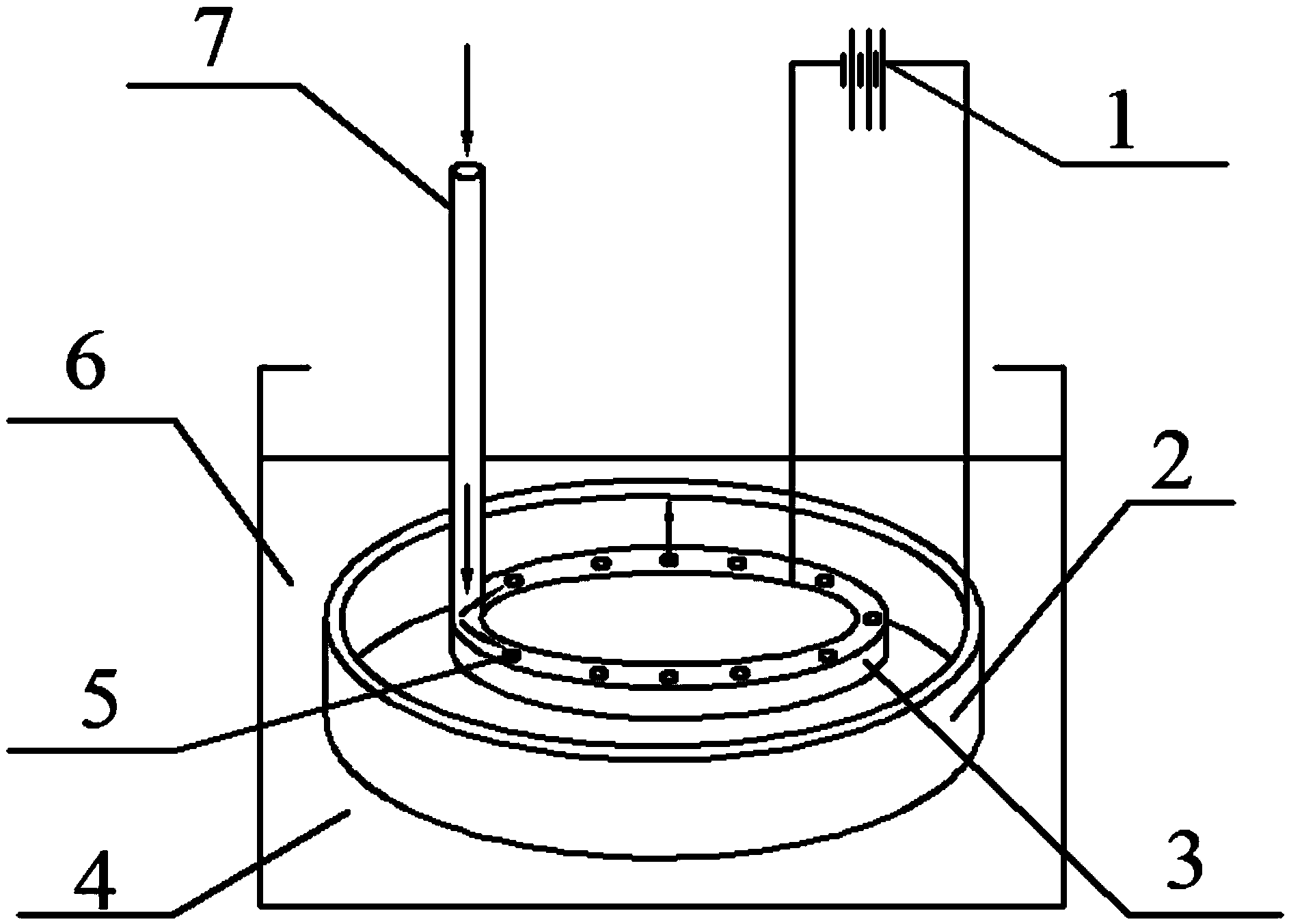

[0017] As shown in Figure 1, the complex regeneration device for complex iron catalysts for natural gas desulfurization includes: electrolysis power supply 1, electrochemical anode 2, electrochemical cathode 3, regeneration reactor 6, and intake pipe 7;

[0018] Complex iron catalyst 4 is housed in regeneration reactor 6;

[0019] The electrochemical anode 2 is a ring structure and is connected to the positive pole of the electrolysis power supply 1;

[0020] The electrochemical cathode 3 adopts the form of an annular coil and is made of pipe material. The electrochemical cathode 3 is connected to the negative electrode of the electrolysis power supply 1; 3. As an oxygen filling channel, air is passed into the electrochemical cathode 3 through the air intake pipe 7, and the air passed in is dispersed and flowed out by a plurality of air outlet holes 5 evenly distributed along the circumference;

[0021] The diameter of the ring of the electrochemical anode 2 is larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com