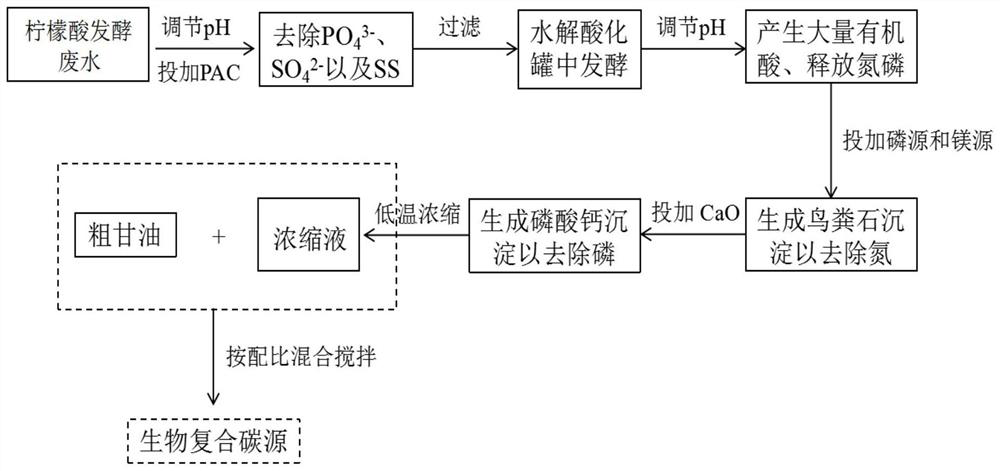

Method for preparing biological composite carbon source from citric acid fermentation wastewater and application of biological composite carbon source

A technology for fermenting wastewater and composite carbon sources, applied in the field of environmental engineering, can solve the problems of waste of resources and increase costs, and achieve the effects of reducing concentration costs, saving resources, and solving complex preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

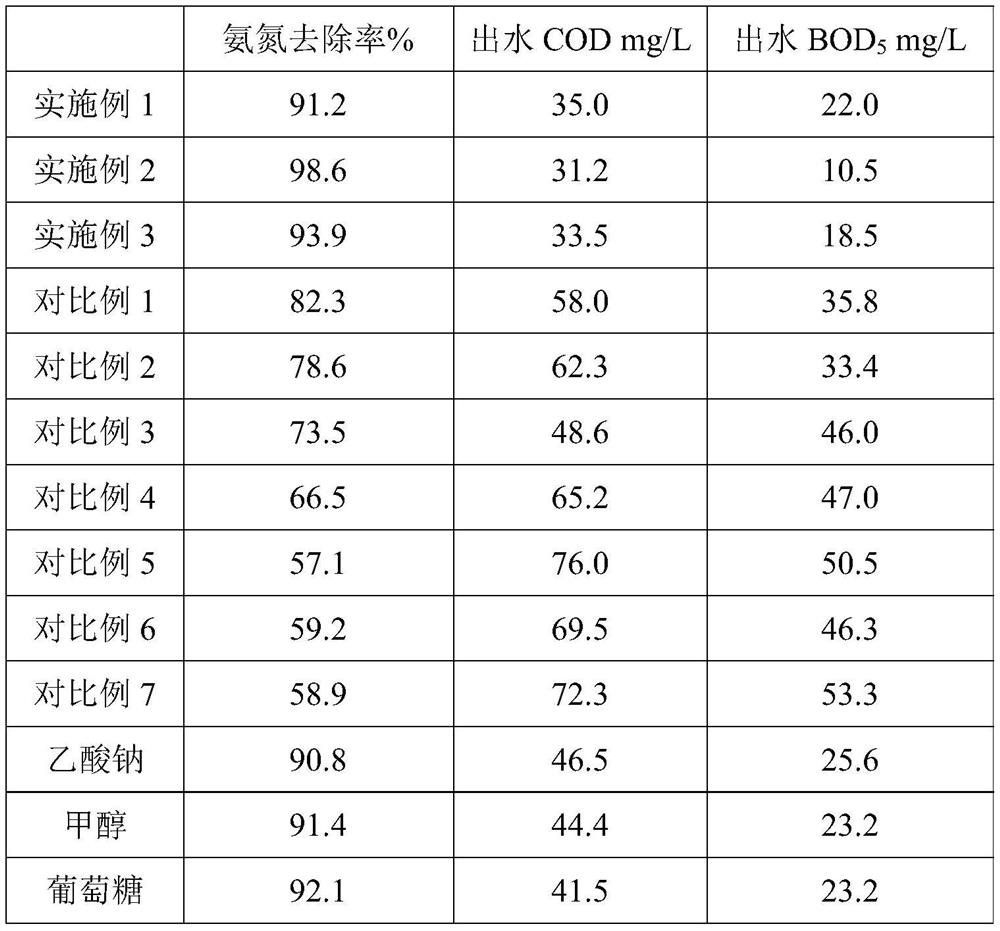

Examples

Embodiment 1

[0054] A method of utilizing citric acid fermentation wastewater to prepare a biological composite carbon source, comprising the following steps:

[0055] (1) Add 50L of citric acid fermentation wastewater to the reaction tank, add 20% (w / w) NaOH solution by mass to adjust its pH value to 9-11, and then add 150g of flocculant polyaluminum chloride (PAC) to stir The reaction time was 1h. After the reaction is completed, stand for 1h and then filter to remove PO in the wastewater 4 3- , SO 4 2- ions and suspended solids (SS).

[0056] (2) adding the filtrate obtained in the step (1) into the hydrolysis and acidification tank, adjusting its pH value to 8-11 and fermenting, a hydraulic transmission system is installed at the bottom of the hydrolysis and acidification tank, and the fermentation is treated by the stirring device arranged in the tank. The wastewater is stirred slowly and uniformly. The fermentation temperature was 35° C., and the fermentation time was 10 days. ...

Embodiment 2

[0063] The difference between this example and Example 1 is that in step (4), based on the total volume of the mixture being 100%, the percentage content of the concentrated solution is 40%; the percentage content of crude glycerol is 35%; The percentage is 25%. Other steps and parameter conditions are the same as in Example 1.

Embodiment 3

[0065] The difference between this example and Example 1 is that in step (4), based on the total volume of the mixture being 100%, the percentage content of the concentrated solution is 45%; the percentage content of crude glycerol is 40%; The percentage is 15%. Other steps and parameter conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com