Clearing device for bolt anti-corrosion oil paint

An anti-corrosion paint and removal device technology is applied in the field of bolt anti-corrosion paint removal devices, which can solve the problems of difficult removal of bolt paint and heavy workload, and achieve the effects of reducing maintenance workload, easy operation, and preventing damage to threads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

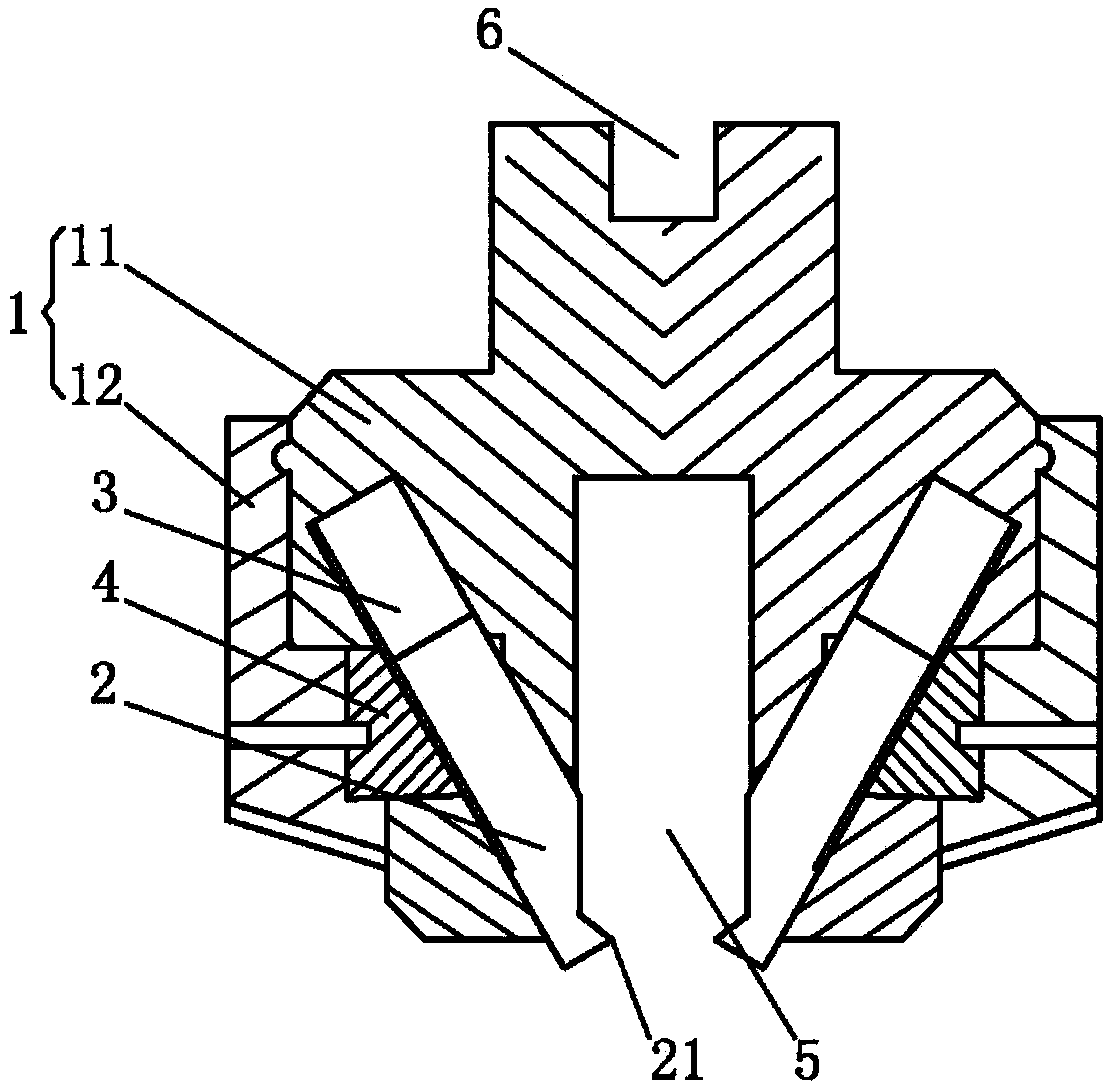

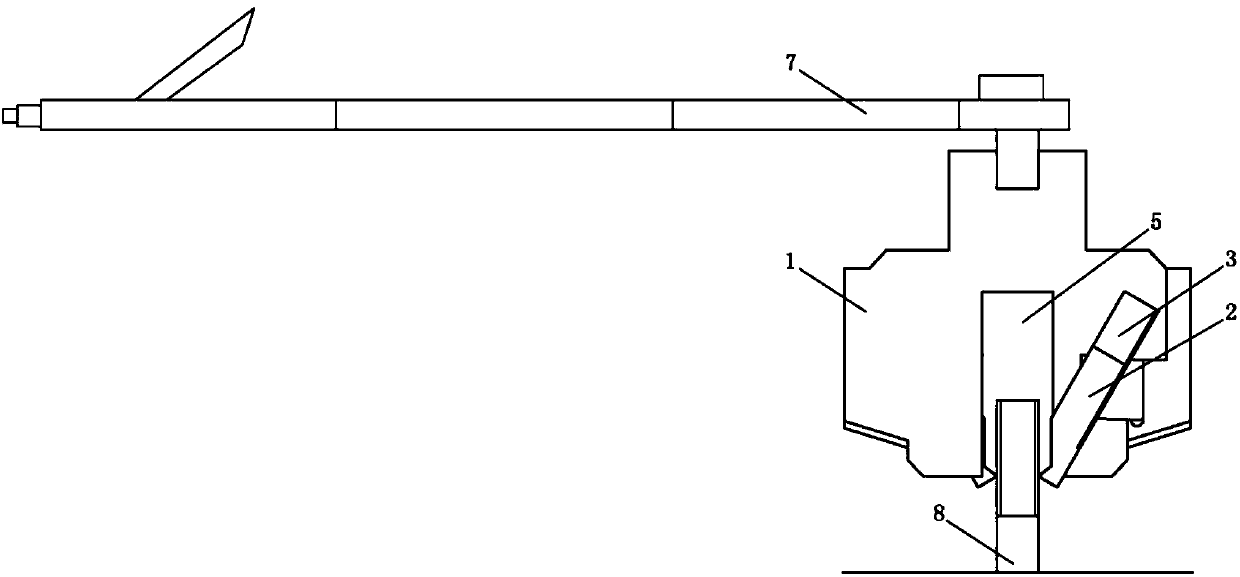

[0022] Such as Figure 1 to Figure 3 As shown, a bolt anti-corrosion paint removal device provided by the embodiment of the present invention includes a body 1, the body 1 is provided with a hole 5 for the screw to penetrate, the body 1 is provided with a cutter 2, and one end of the cutter 2 A knife point 21 protruding into the hole 5 from the side of the hole 5 is provided. The shape of the knife point 21 is a triangle or a trapezoid that fits with the thread. The knife point 21 is preferably triangular, and the tip angle of the knife point is 45 degrees. . When the material of the knife tip 21 is selected, it should be taken into account that the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com