Novel tub for washing machine

A washing machine drum and washing machine technology, applied in other washing machines, washing devices, textiles and paper making, etc., can solve problems affecting washing quality, small gaps, and difficult removal of dirt and mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

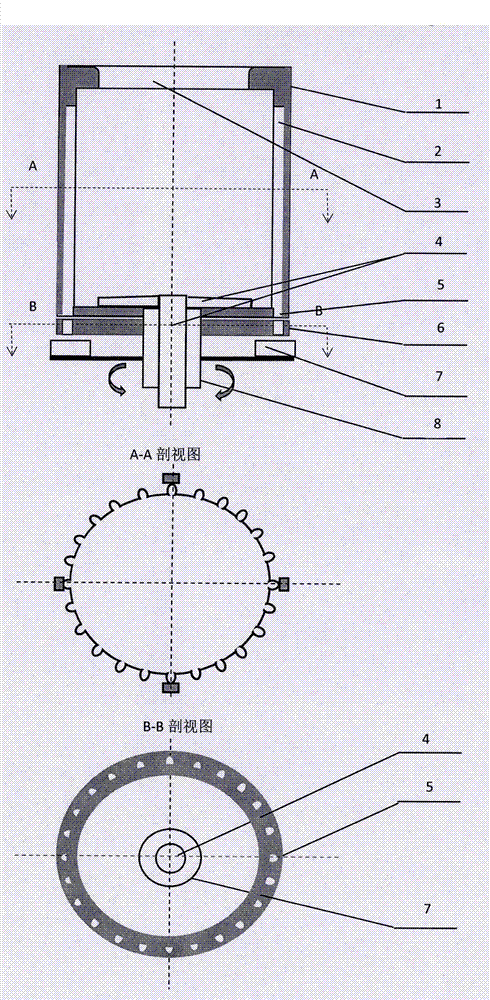

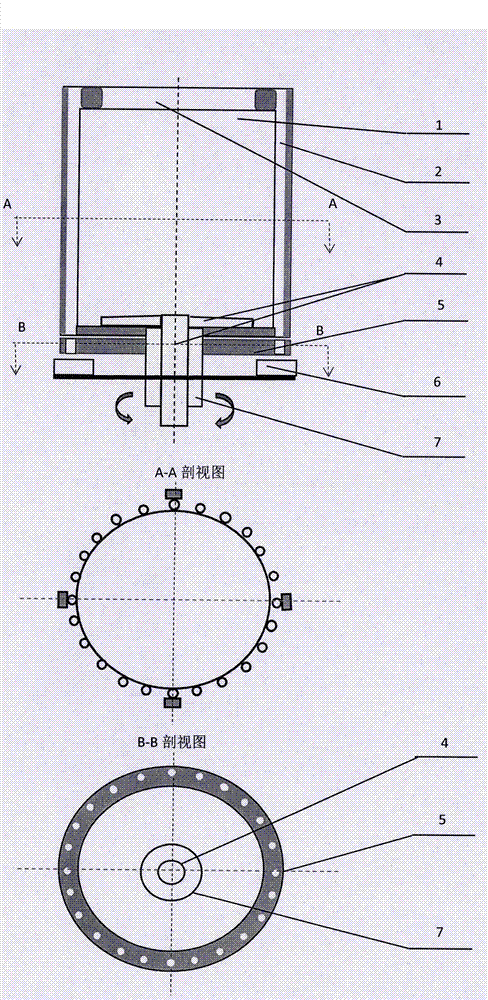

[0015] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

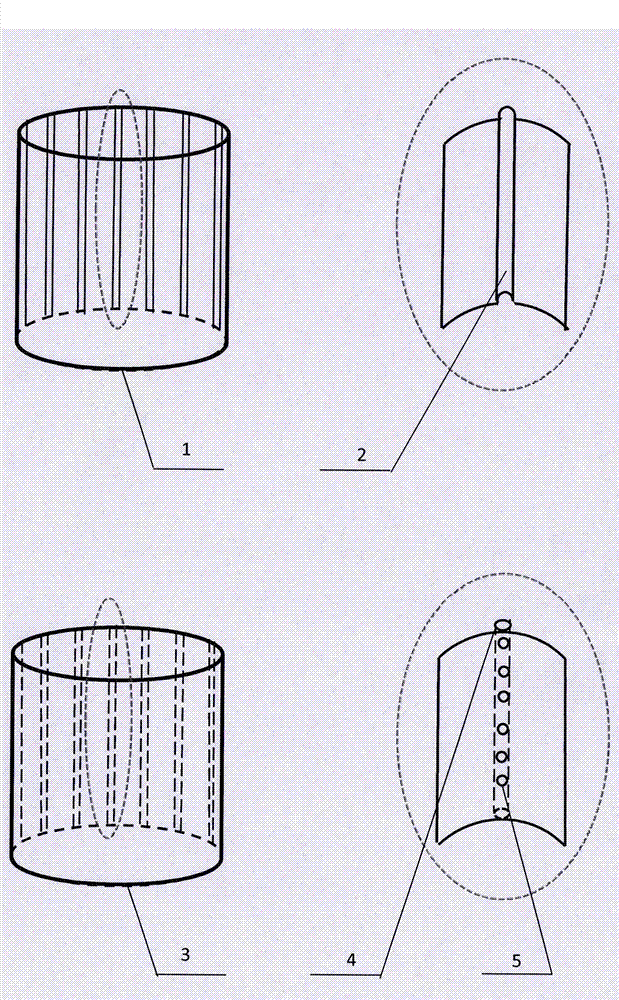

[0016] 1. Vertical groove or vertical pipe arrangement for the drum of the vertical drum washing machine:

[0017] exist figure 2 Among them, several vertical grooves (2) are arranged on the inner wall of the drum body (1), and each vertical groove (2) is connected with the through hole (5) at the bottom of the drum, and the through hole (5) at the bottom of the drum is connected with the opening and closing mechanism (6). ) connected. When the opening and closing mechanism is in the closed state, the drum stores washing liquid, and when it is in the open state, the washing liquid is discharged along the vertical groove. When washing, the clothes and washing liquid are put into the drum through the drum inlet (3), and when the washing liquid is discharged, the washing liquid is discharged to the water receiving tank (7) through the vertical groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com