Resource comprehensive utilization method of refining alkaline slag

A technology of alkali slag and refining, which is applied in the field of comprehensive resource utilization of refining and chemical alkali slag, which can solve the problems of waste of inorganic salts such as sodium sulfate, weak research foundation, and restriction of the development of alkali slag, and achieve industrial water saving and safe and reliable operation Low management and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

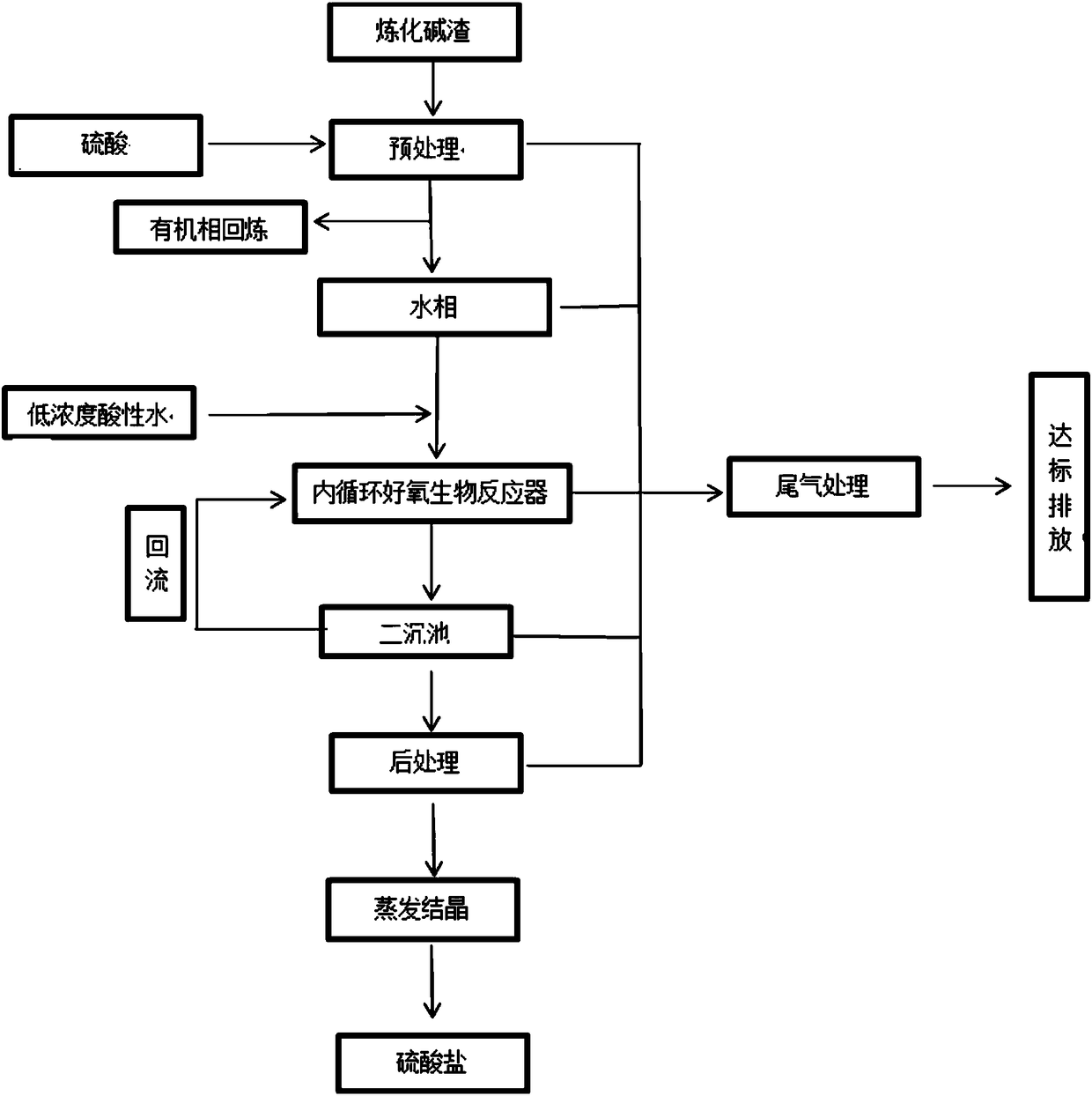

Image

Examples

Embodiment 1

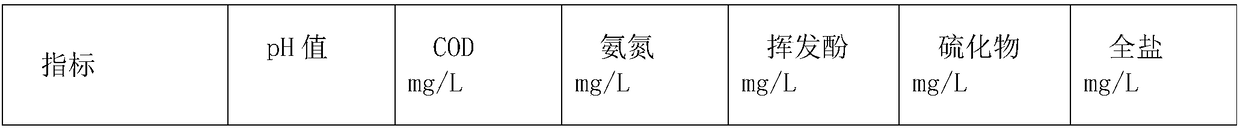

[0039] The specific indicators of the liquefied gas alkali slag of a refining and chemical enterprise are shown in Table 1:

[0040] Table 1. Liquefied petroleum gas alkali residue index

[0041]

[0042]

[0043] The low-concentration acidic water indicators are shown in Table 2:

[0044] Table 2. Low-concentration acidic water indicators

[0045]

[0046] 1) The alkali residue of liquefied gas enters the adjustment tank through the metering pump and 50% sulfuric acid at the same time. The volume ratio of alkali residue to sulfuric acid is 25:1, and the pH value after full reaction is 10.4. The organic phase enters the organic phase storage tank through the overflow. After dehydration, the water phase of alkali residue enters the water phase storage tank.

[0047] 2) The alkaline residue water phase enters the internal circulation aerobic bioreactor from the water phase storage tank through the metering pump. The volume ratio of the alkaline residue water phase to the low-concentratio...

Embodiment 2

[0052] The specific indicators of gasoline alkali residue from a refinery and chemical enterprise are shown in Table 3:

[0053] Table 3. Indicators of gasoline alkali residue

[0054]

[0055] The low-concentration acidic water indicators are shown in Table 4:

[0056] Table 4. Low-concentration acidic water indicators

[0057]

[0058] 1) Gasoline alkali residue enters the adjustment tank simultaneously with 30% sulfuric acid through a metering pump. The volume ratio of alkali residue to sulfuric acid is 15:1. After full reaction, the pH value is about 9.2. The organic phase enters the organic phase storage tank through the overflow and is dehydrated. After refining, the alkaline residue water phase enters the water phase storage tank.

[0059] 2) The alkali residue water phase enters the internal circulation aerobic bioreactor from the water phase storage tank via the metering pump. The volume ratio of the alkali residue water phase to the low-concentration acidic water is 1:4. Set ...

Embodiment 3

[0064] For the diesel soda slag of a refining and chemical enterprise, the specific indicators are shown in Table 5:

[0065] Table 5. Diesel alkali residue indicators

[0066]

[0067] See Table 6 for low-concentration acidic water indicators:

[0068] Table 6. Low-concentration acidic water indicators

[0069]

[0070] 1) The alkali residue of liquefied gas enters the adjustment tank simultaneously with 98% sulfuric acid through a metering pump. The volume ratio of alkali residue to sulfuric acid is 50:1, and the pH value after full reaction is 9.7. The organic phase enters the organic phase storage tank through the overflow. After dehydration and refining, the aqueous phase of alkali residue enters the water phase storage tank.

[0071] 2) The alkali residue water phase enters the internal circulation aerobic bioreactor from the water phase storage tank via the metering pump. The volume ratio of the alkali residue water phase to the low-concentration acid water is 1:6. Set the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com