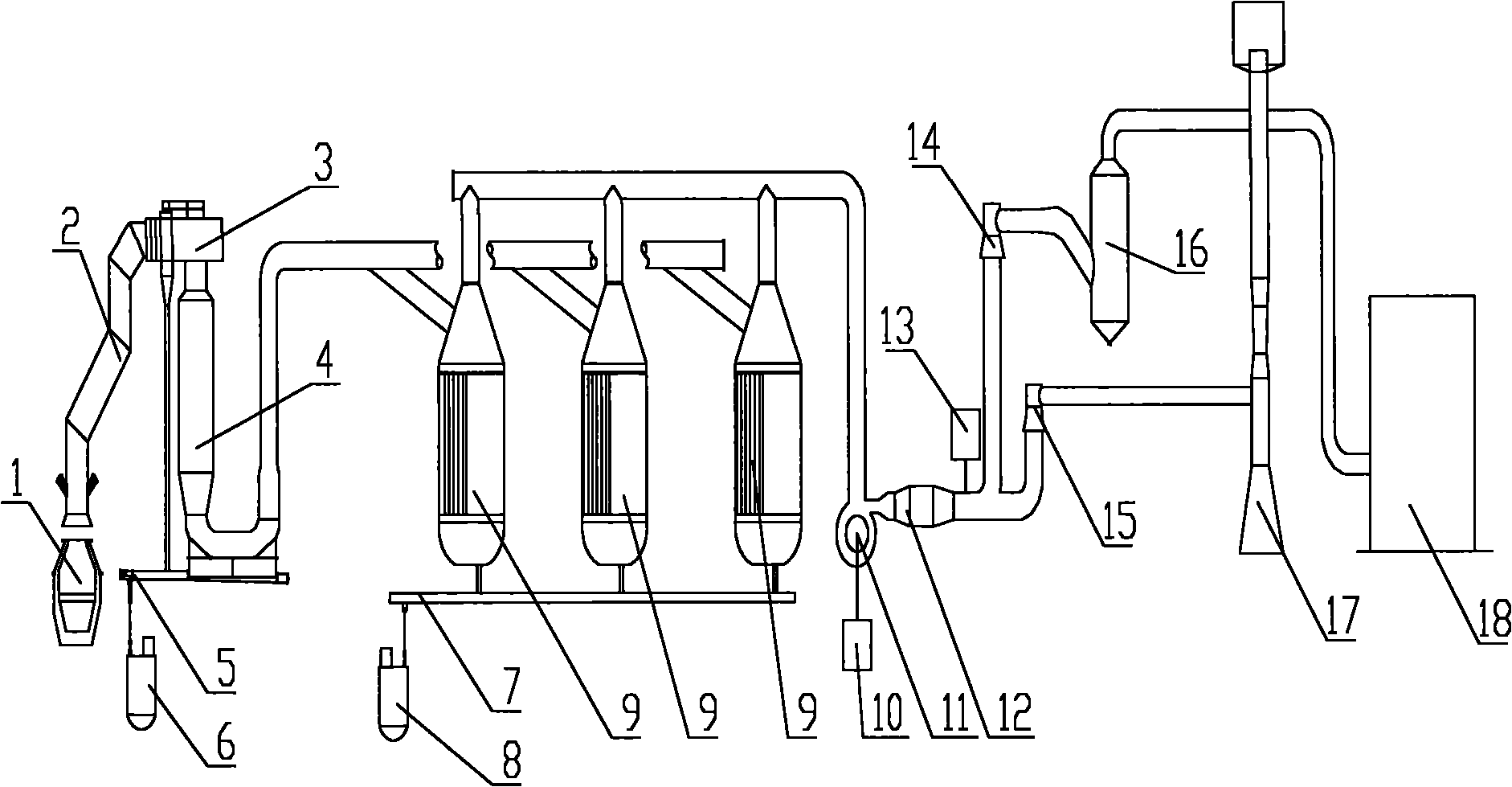

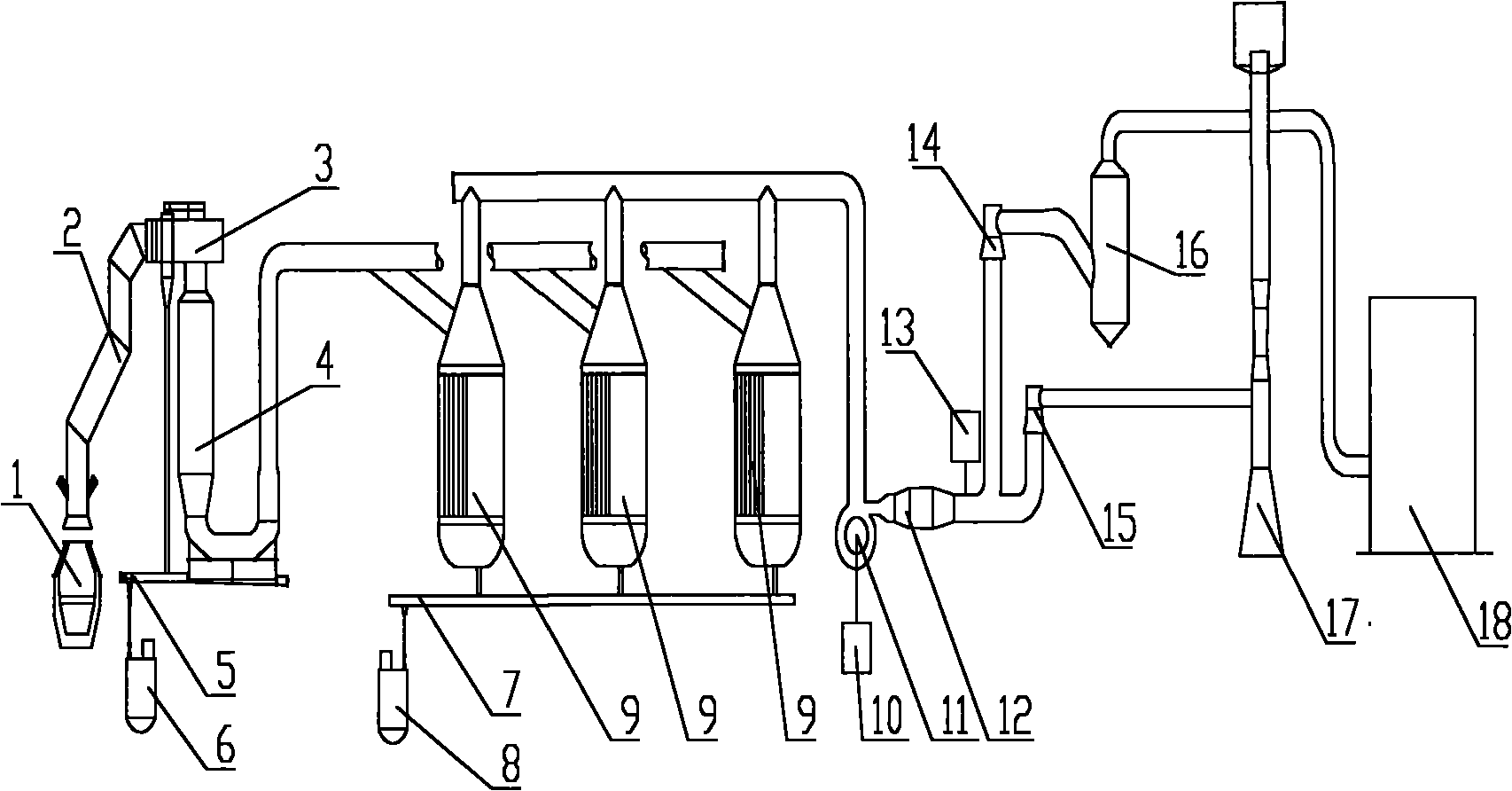

Process and equipment for dust collection and heat recovery by converter gas dry method

A converter gas, dry dust removal technology, applied in lighting and heating equipment, process efficiency improvement, furnace and other directions, can solve problems such as waste of industrial water, high failure rate of electrostatic precipitators, inability to achieve dust removal effect, etc., to achieve dust removal effect Significantly reduce the effect of explosion hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] According to the attached figure 1 As a specific embodiment description, the converter gas enters the vaporization cooling flue (2) from the converter (1), and the temperature drops from about 1450°C to 800-1000°C. After entering the spark arrestor (3), the converter gas separates the sparking coarse particles that are easy to cause explosion in (3). Then it enters the waste heat boiler (4) and is cooled to about 200°C, and the steam collected by the waste heat boiler can be used for power generation or other purposes. The coarse dust collected from the spark arrestor (3) and the waste heat boiler (4) enters the coarse ash storage bin (6) through the coarse ash conveying device (5) at the lower part thereof. Afterwards, the converter gas enters the nitrogen pulse gas bag filter (9), and the fine dust is removed, and the dust accumulated on the cloth bag is blown off by the nitrogen pulse blowback, and the fine dust collected by the nitrogen pulse gas bag filter (9) pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com