Combination air cooler and circulating cooling water system based on same and method

A technology of air coolers and coolers, which is applied in the field of circulating cooling water systems and air coolers. It can solve the problems of increasing the operating load of cooling tower spray pumps and fans, affecting the production cost of calcium carbide products, and large consumption of soft water evaporation. Hazard of equipment freezing, load reduction, effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

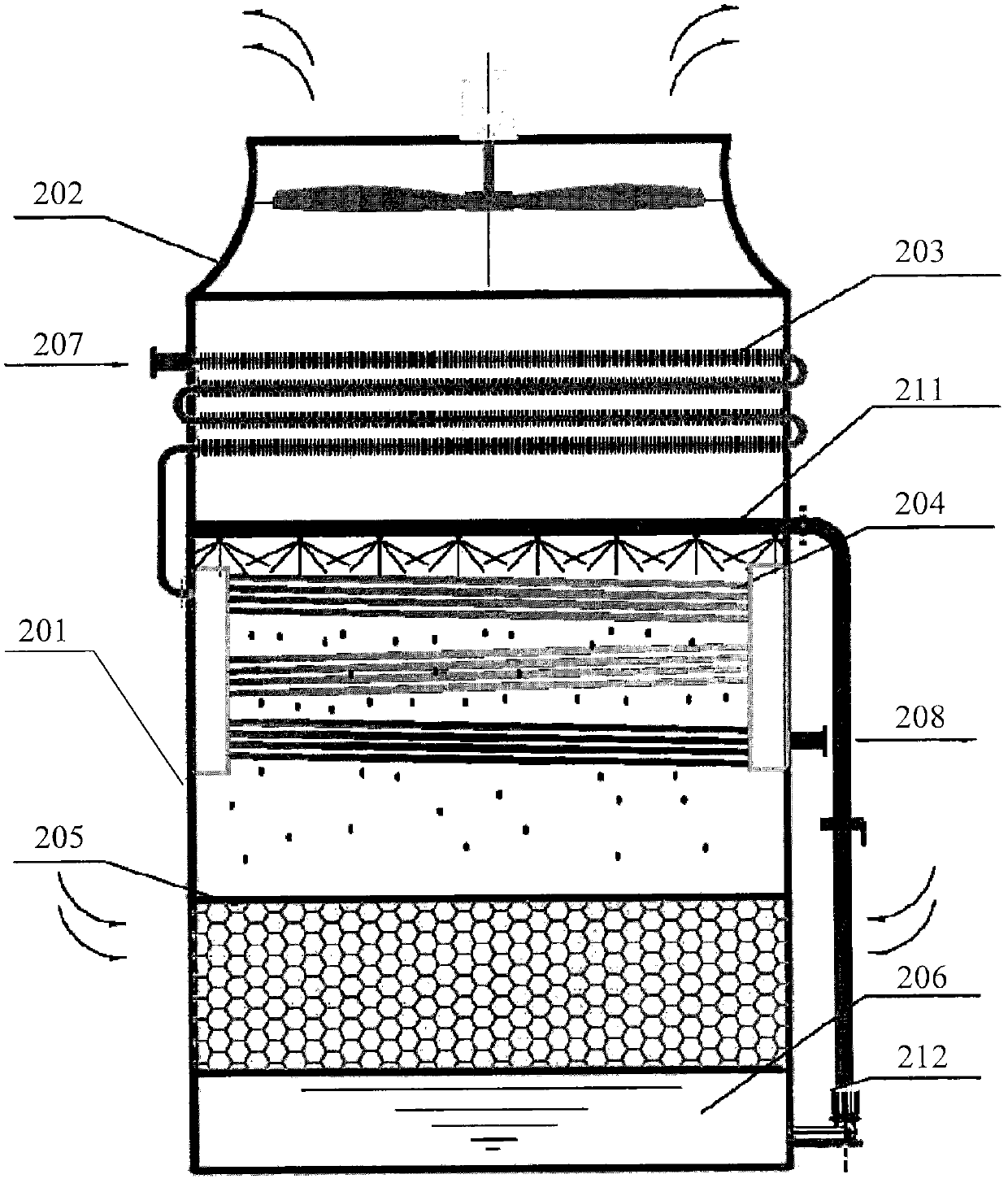

[0027] Below, refer to figure 2 One embodiment of the combined air cooler of the present invention will be described.

[0028] The combined air cooler includes a box body 201 , a hyperbolic air duct 202 from bottom to top in the box body 201 , a dry cooling part 203 , a wet cooling part 204 , an air inlet 205 and a spray water tank 206 . The combined air cooler also includes a process medium inlet 207 leading into the dry cooling part 203 on one side of the box body 201 and a process medium outlet 208 drawn from the wet cooling part 204 . The dry cooling part 203 includes a finned air precooling tube bundle, and the finned air precooling tube bundle is composed of coil-shaped heat exchange tubes. The wet cooling part 204 sequentially includes a spray system 211 and an evaporative cooling tube bundle from top to bottom. Wherein, the evaporative cooling tube bundle is composed of inclined heat exchange tubes arranged at an angle with the horizontal plane, the spray system 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com