Method for recycling and utilizing CdS waste liquor produced in production process of copper indium gallium selenide (CIGS) film solar cell

A thin film solar cell, copper indium gallium selenide technology, applied in chemical instruments and methods, energy waste water treatment, cadmium sulfide and other directions, can solve problems such as environmental pollution, and achieve the effect of reducing energy consumption and saving industrial water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

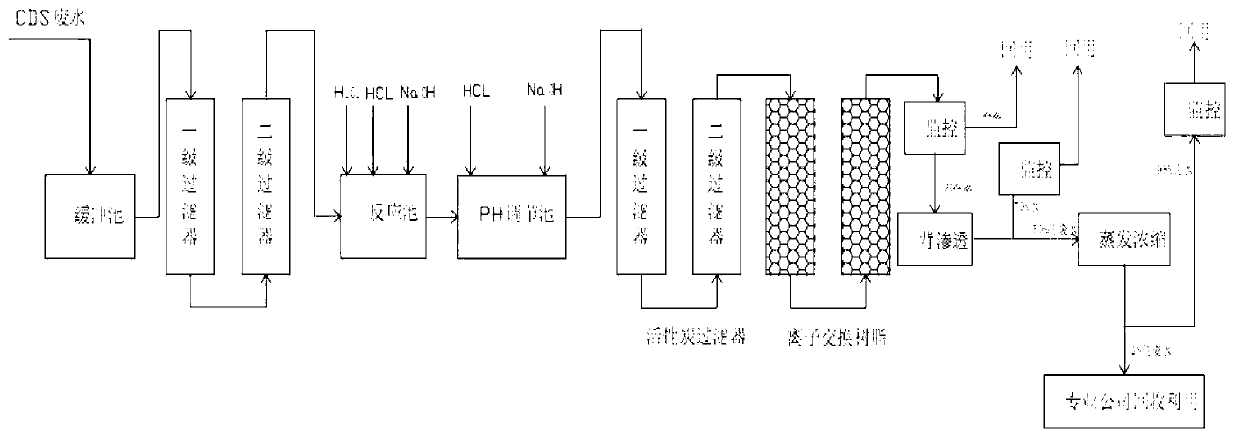

[0027] The present invention will now be further described in detail with reference to the accompanying drawings. figure 1 , 2 , The specific implementation is:

[0028] Filter out the cadmium sulfide CdS in the waste liquid: The CdS waste liquid produced in the production of CIGS thin film solar cells is filtered through a buffer tank and then filtered through a secondary filter to filter out CdS particles in the waste liquid. , The secondary filter contains two separation membranes with different pore sizes, the first one is a 400 nm pore size filter membrane, and the second is a 250 nm pore size filter membrane. Yellow waste liquid containing cadmium sulfide, such as figure 2 As shown, after filtering through the secondary filter, the unique Tyndall effect of the colloidal solution can be clearly observed. After the first filter membrane is filtered, the solution becomes clear and the Tyndall phenomenon is faintly visible, such as image 3 Shown. After filtering through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com