Patents

Literature

221 results about "Copper indium diselenide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

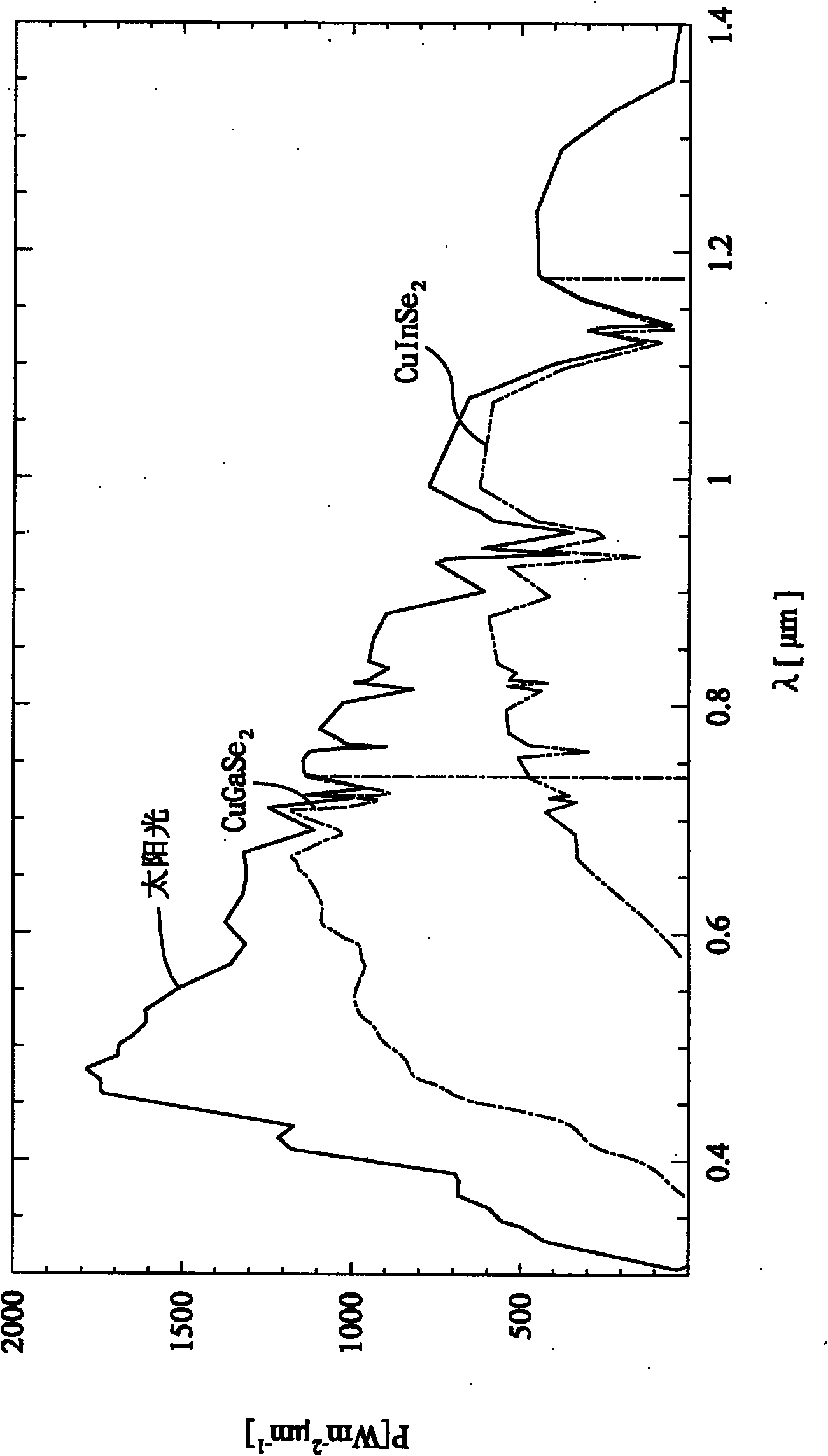

Copper indium gallium (di)selenide (CIGS) is a I-III-VI2 semiconductor material composed of copper, indium, gallium, and selenium. The material is a solid solution of copper indium selenide (often abbreviated "CIS") and copper gallium selenide.

Precursor ink for producing IB-IIIA-VIA semiconductors

InactiveUS20090260670A1Overcome disadvantagesFinal product manufacturePV power plantsIndiumSemiconductor thin films

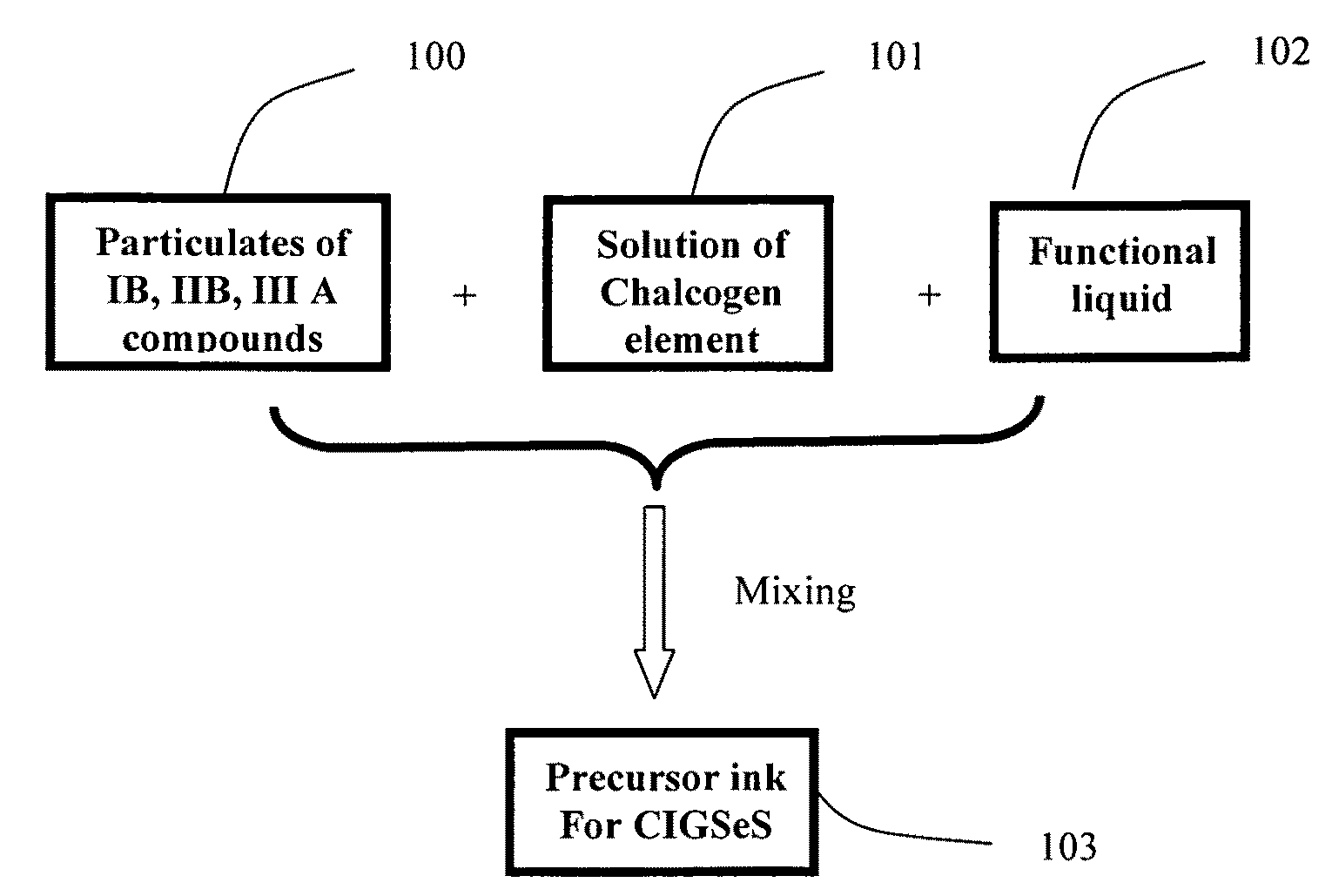

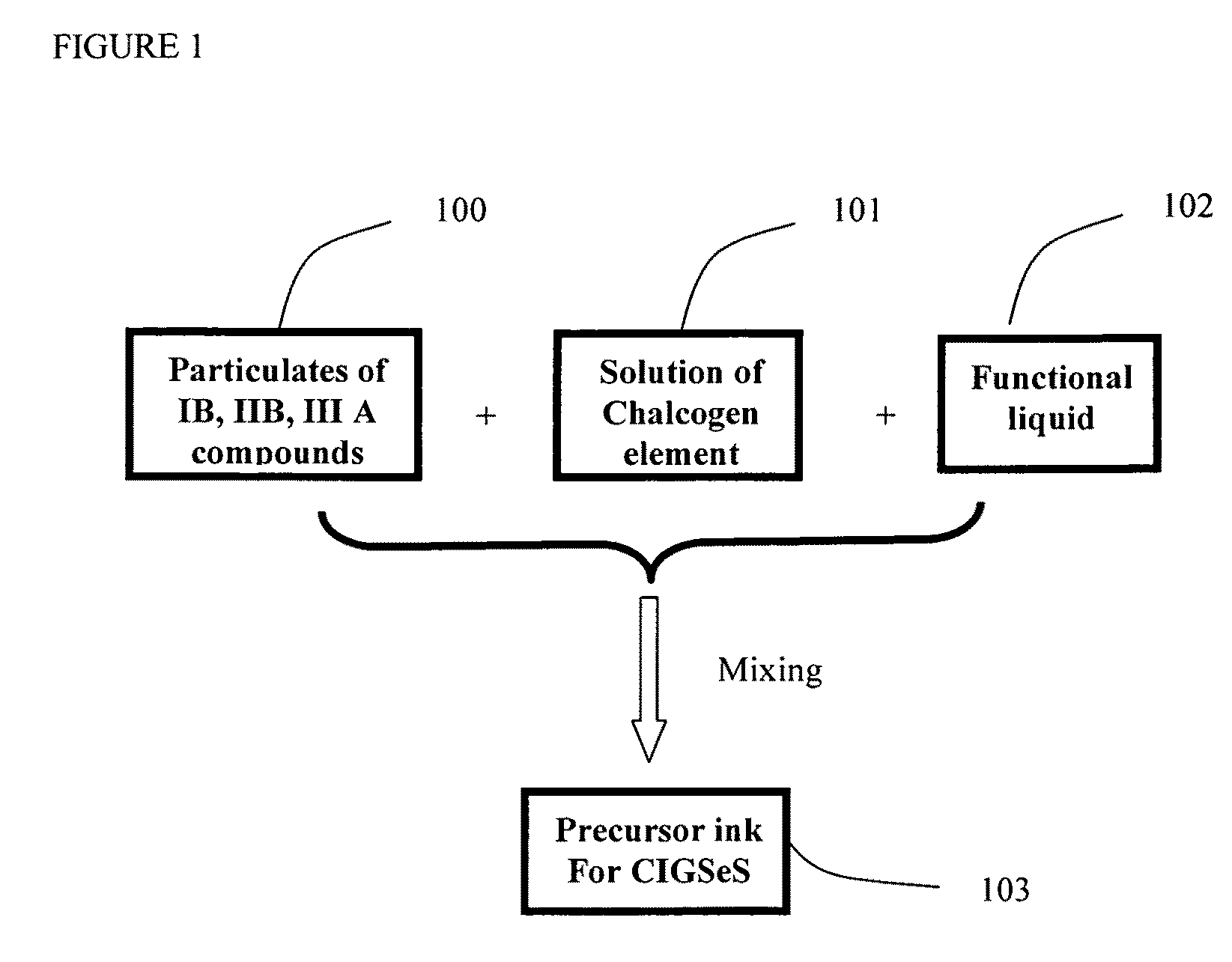

Copper indium diselenide, copper indium gallium diselenide, and other IB-IIIA-VIA compounds are produced by the liquid deposition on a substrate of a precursor-containing ink, followed by heating to produce the desired material. The precursor containing ink is a mixture of three parts. The first part is plurality of particulates of metal compounds of IB, IIIA. The second part is chalcogen source of selenium, sulfur, or organic chalcogen compounds dissolved in a liquid organic solvent. The third part solution function as viscosity adjustment, as introduction of dopant of sodium ion and / or as ink stabilizer. The precursor ink can be coated on substrate at room temperature and it can be transferred into copper indium (gallium) chalcogenide semiconductor thin film upon baking and a chalcogenization process. The resulting thin film semiconducting material can be incorporated into photovoltaic and other electronic devices.

Owner:LI XIAO CHANG CHARLES

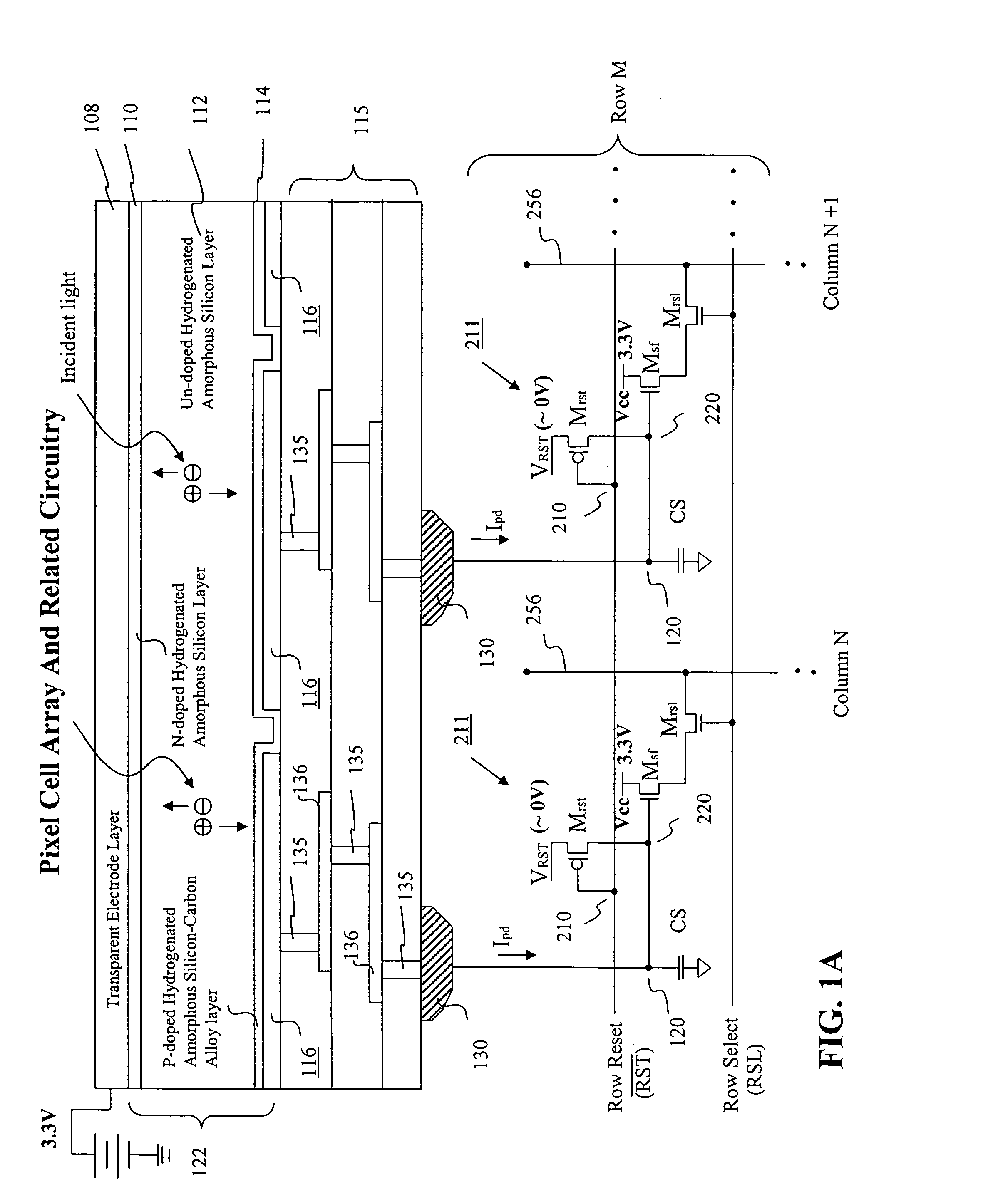

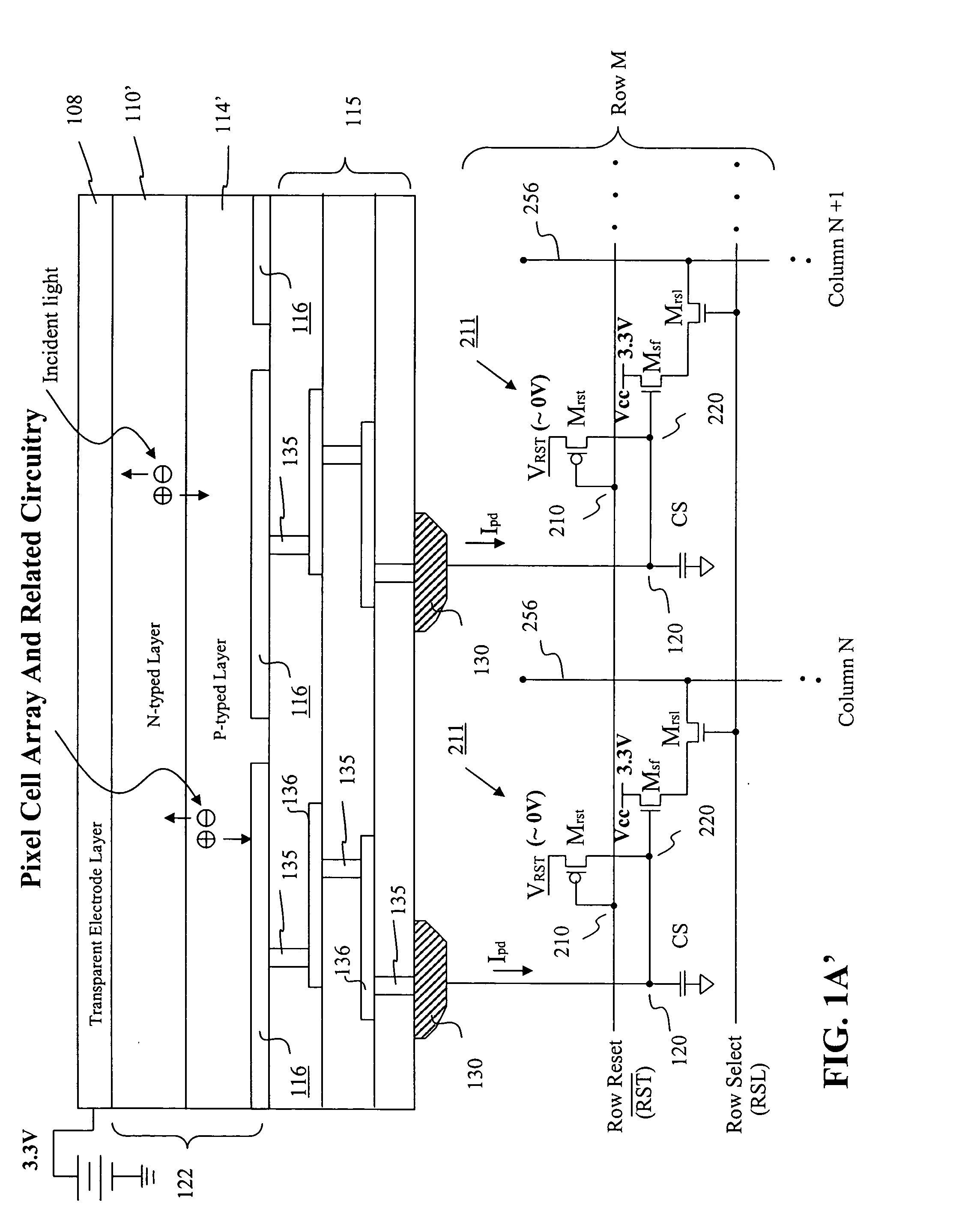

Visible/near infrared image sensor

InactiveUS20050104089A1Improve performanceHigh sensitivityTelevision system detailsTelevision system scanning detailsLow earth orbitBeam steering

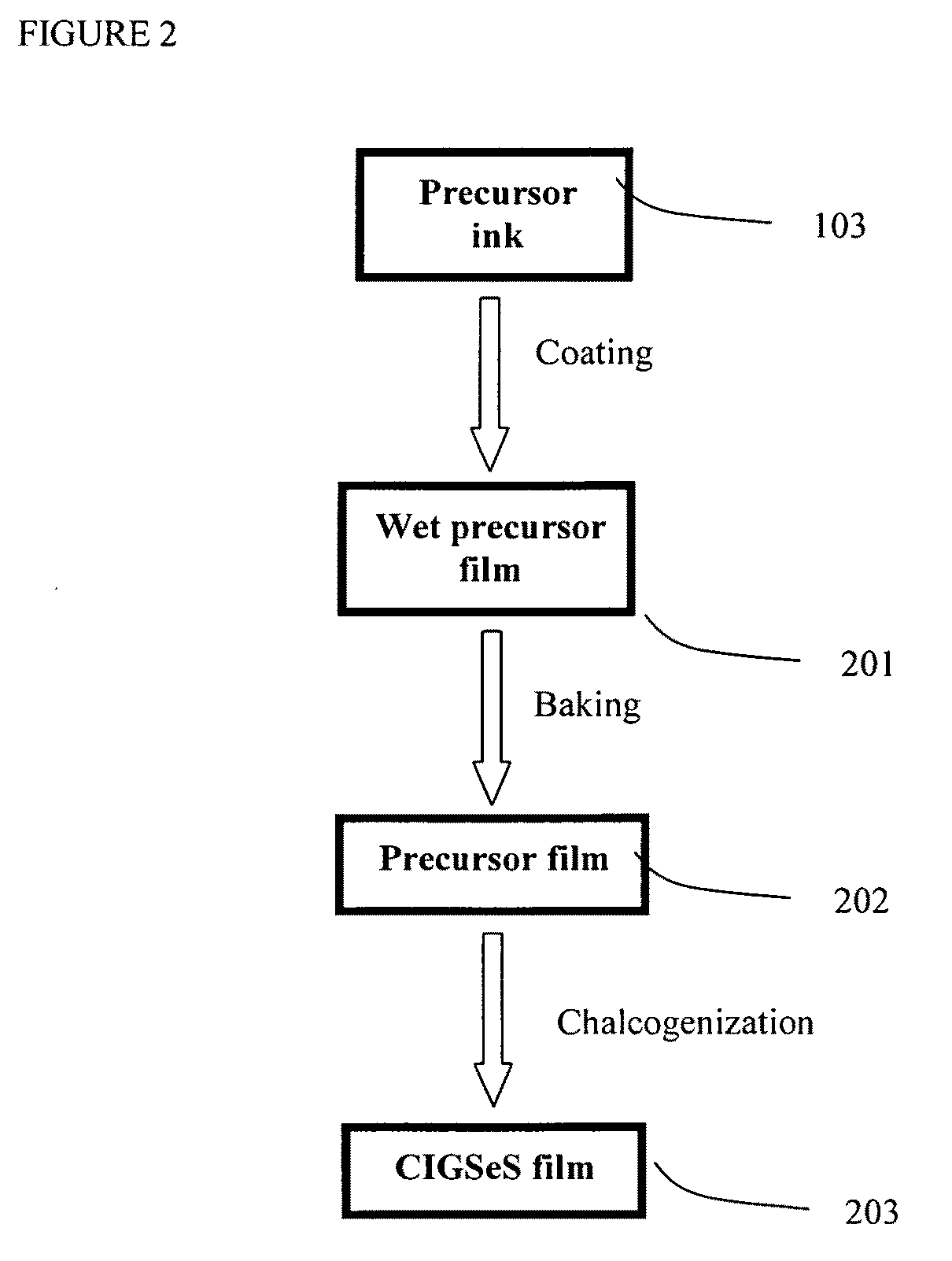

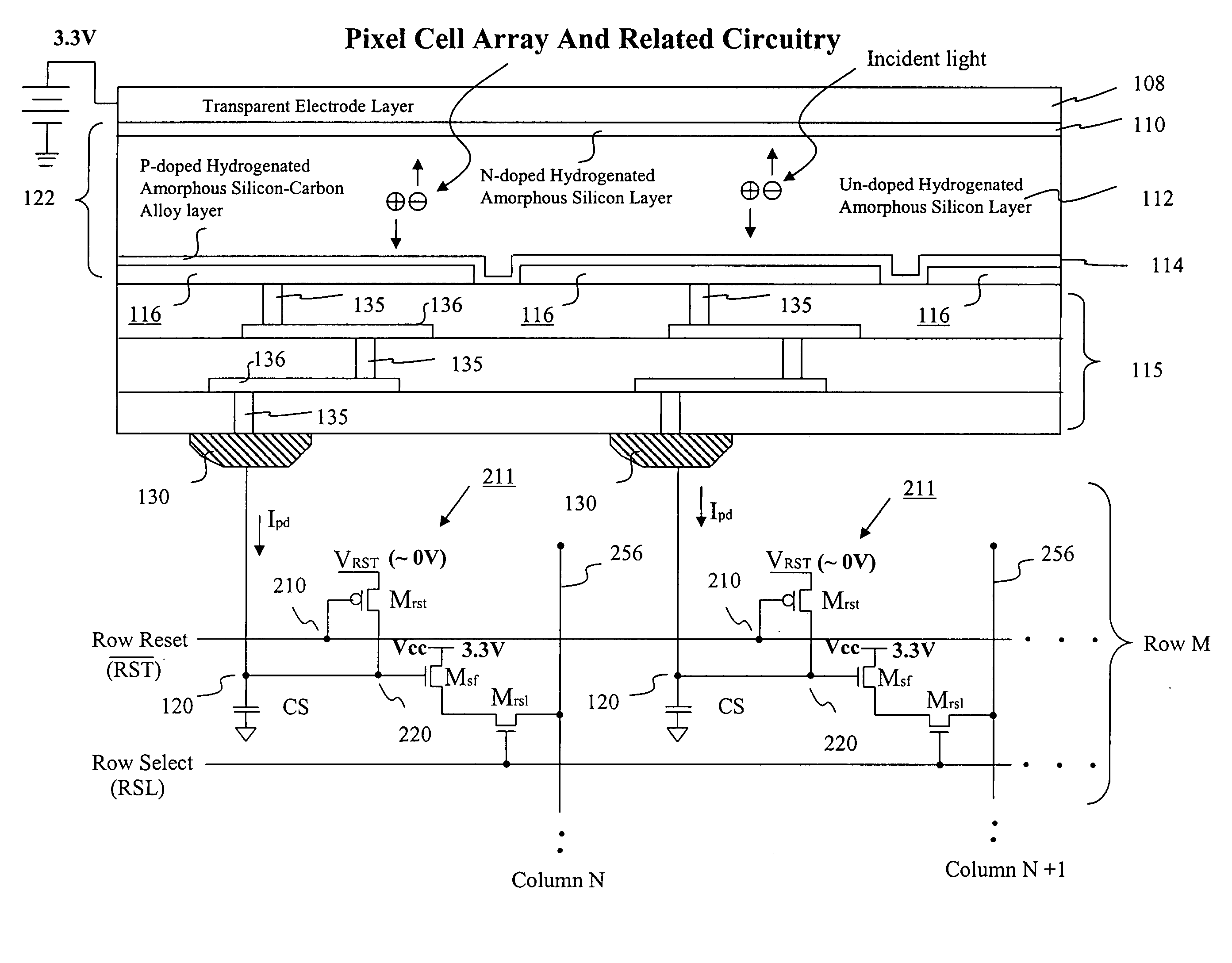

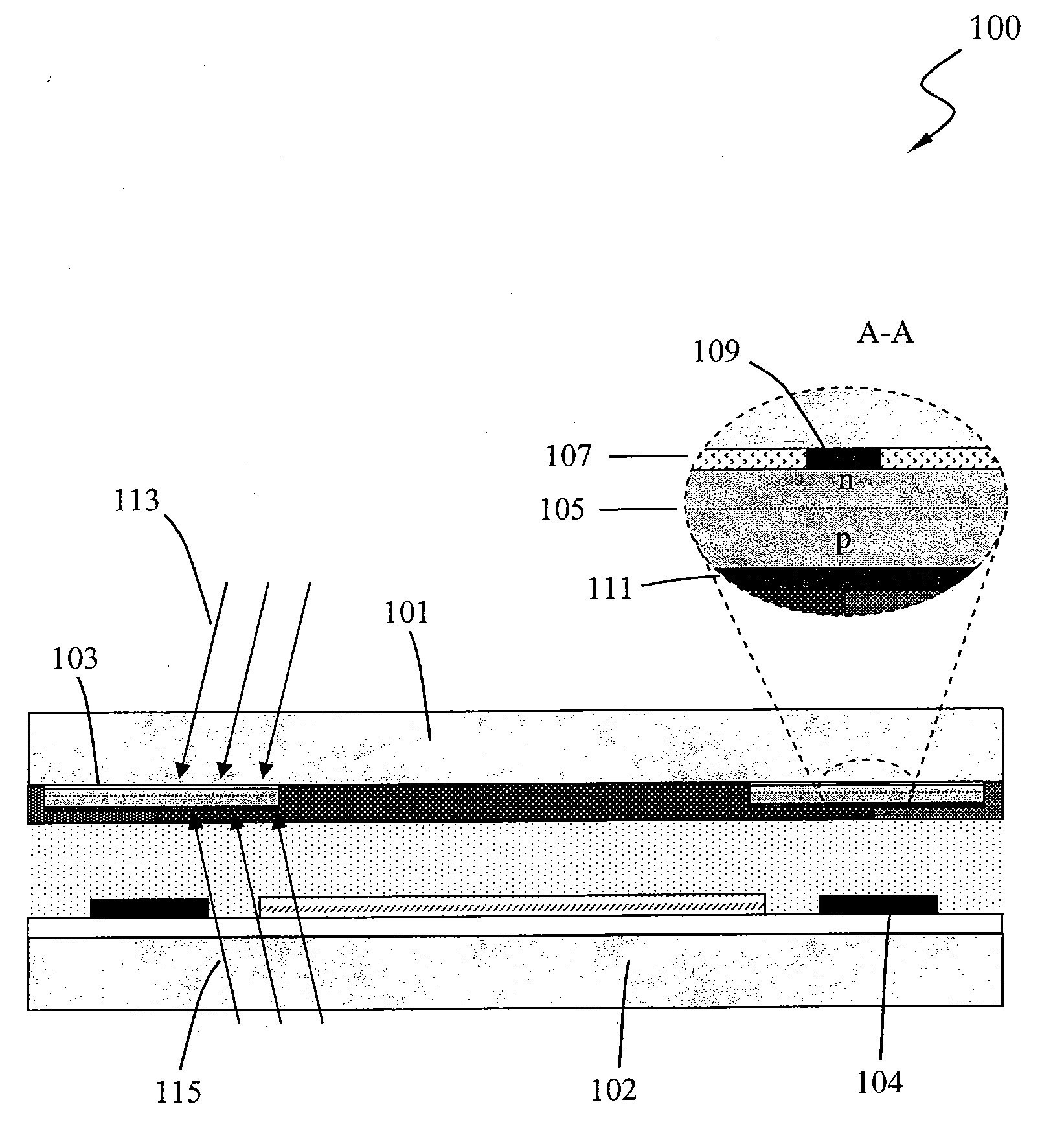

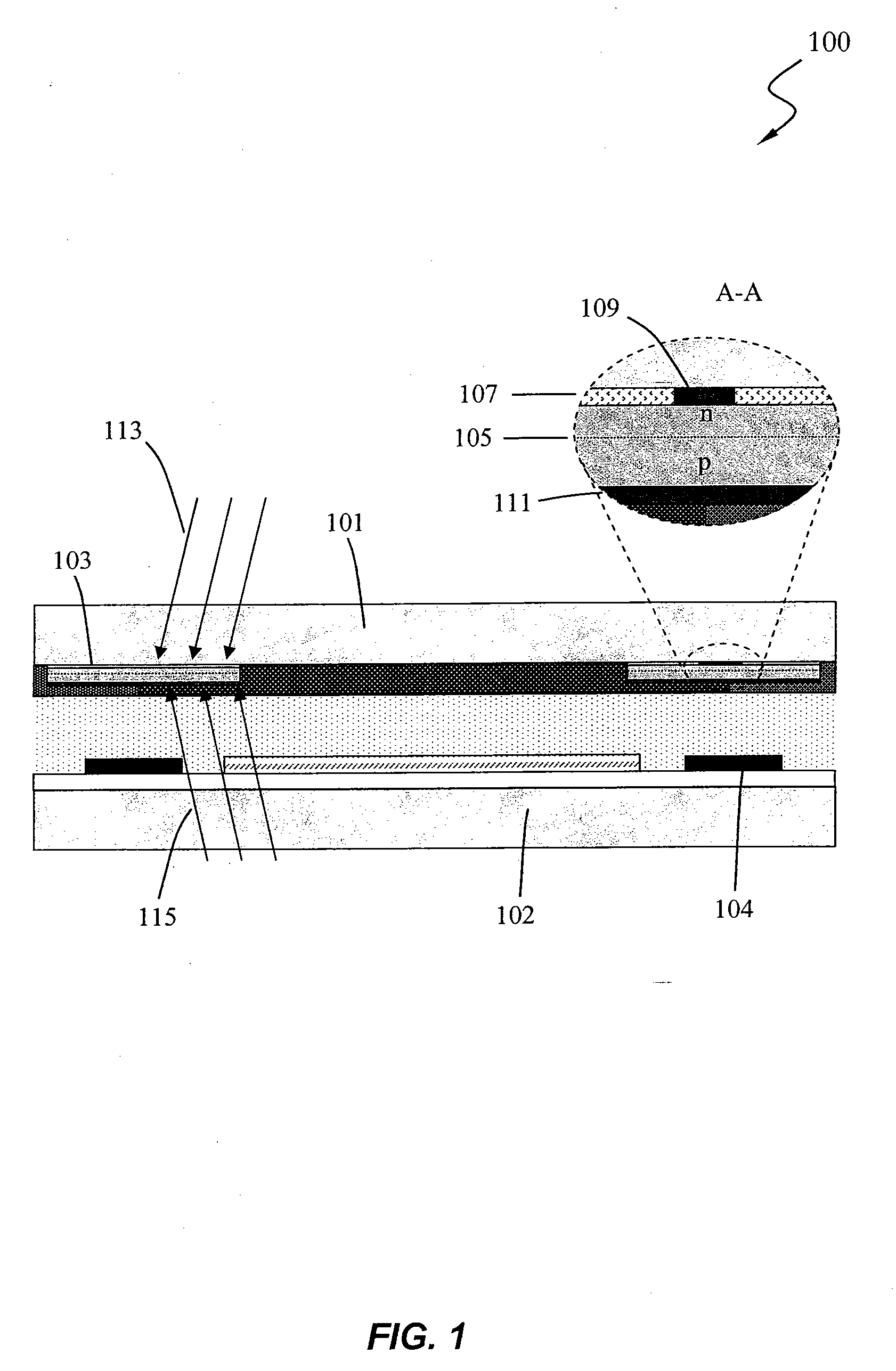

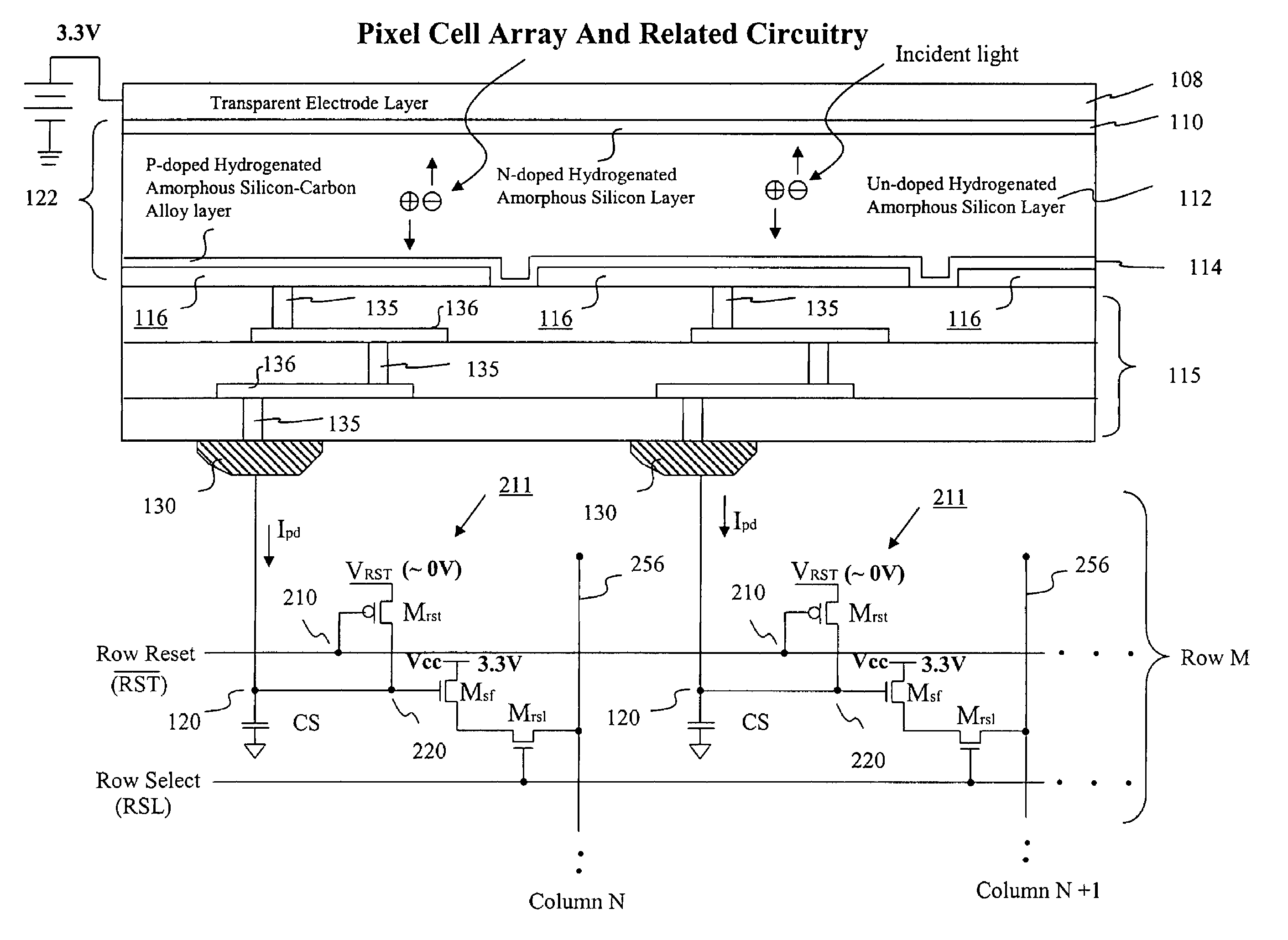

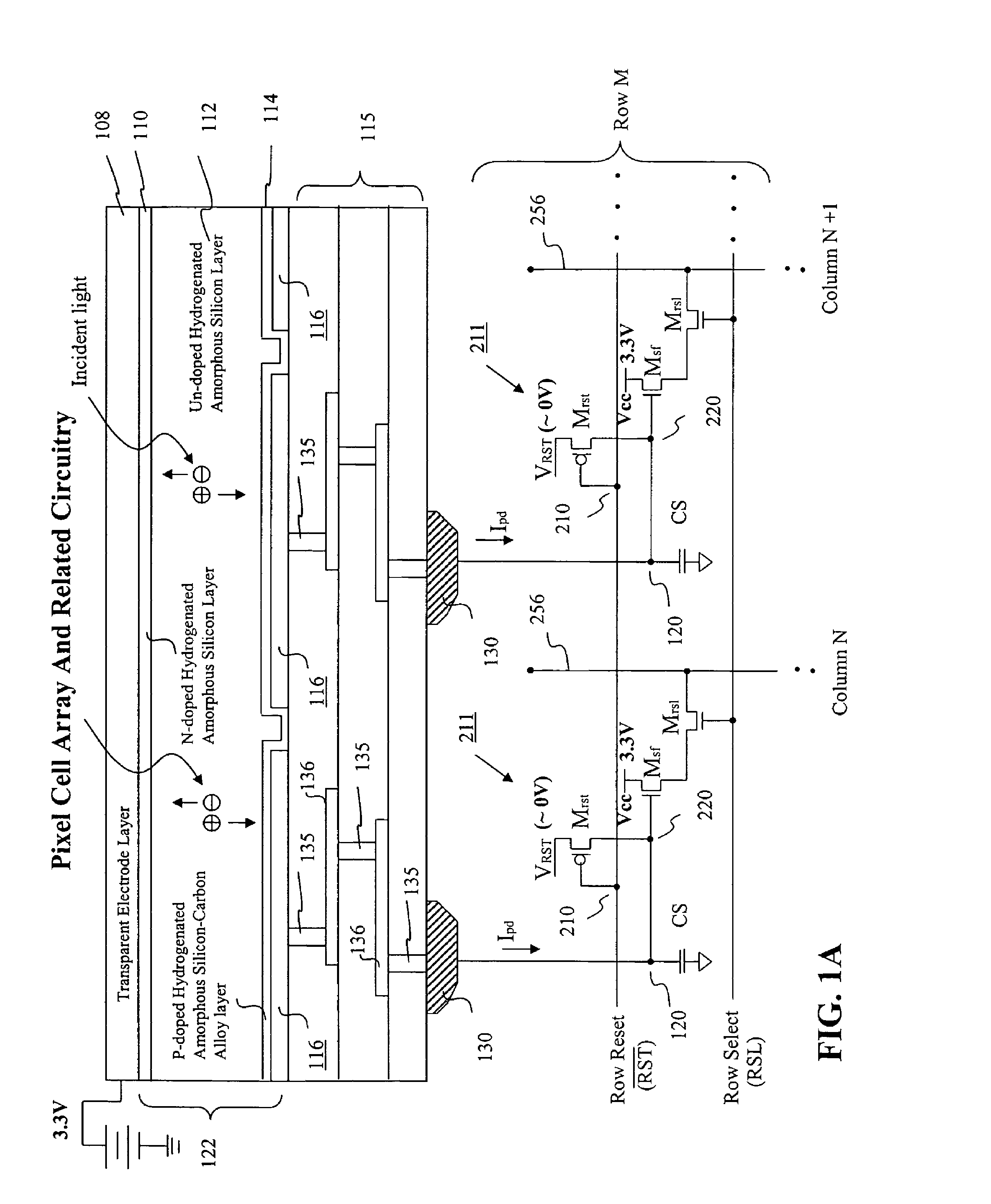

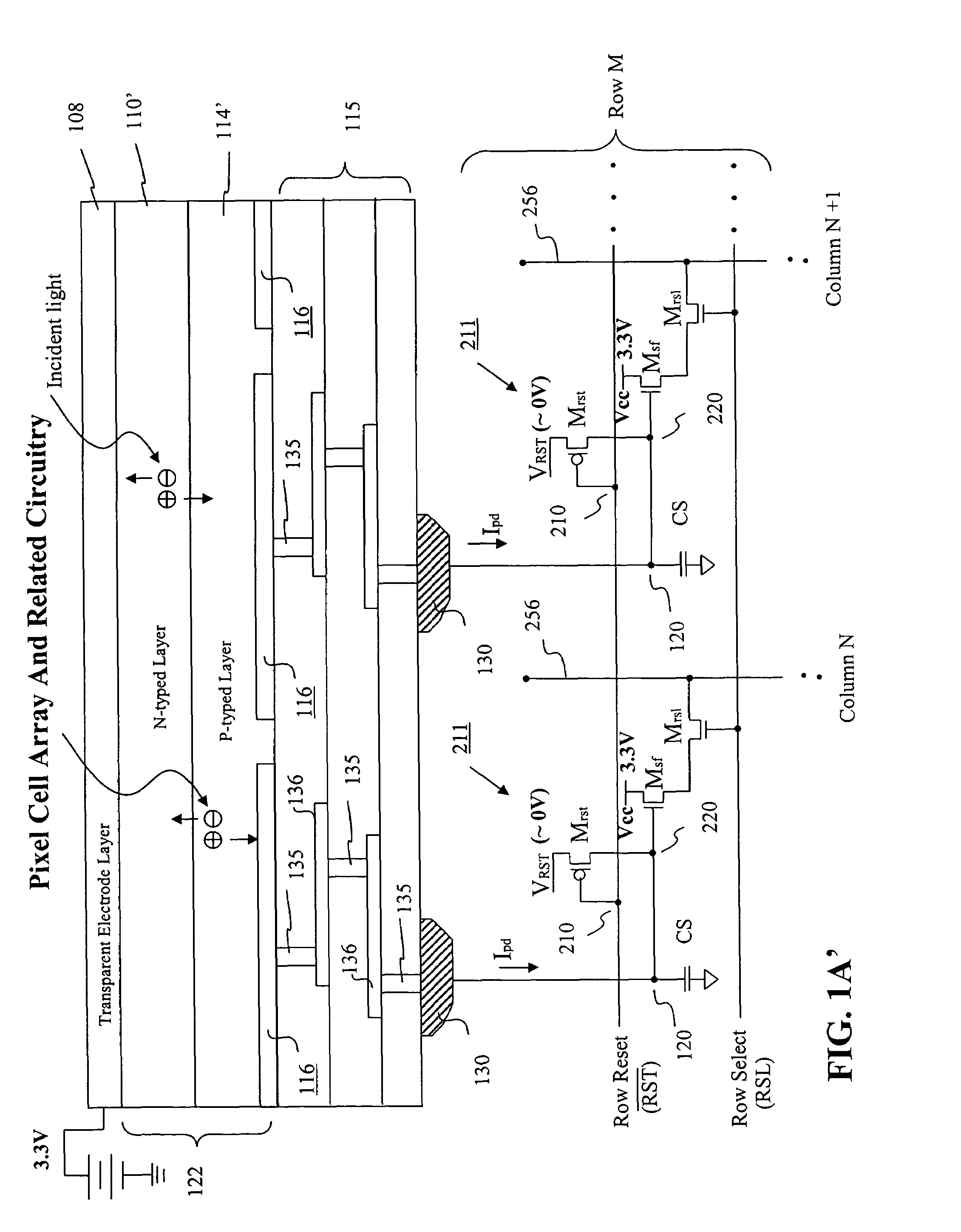

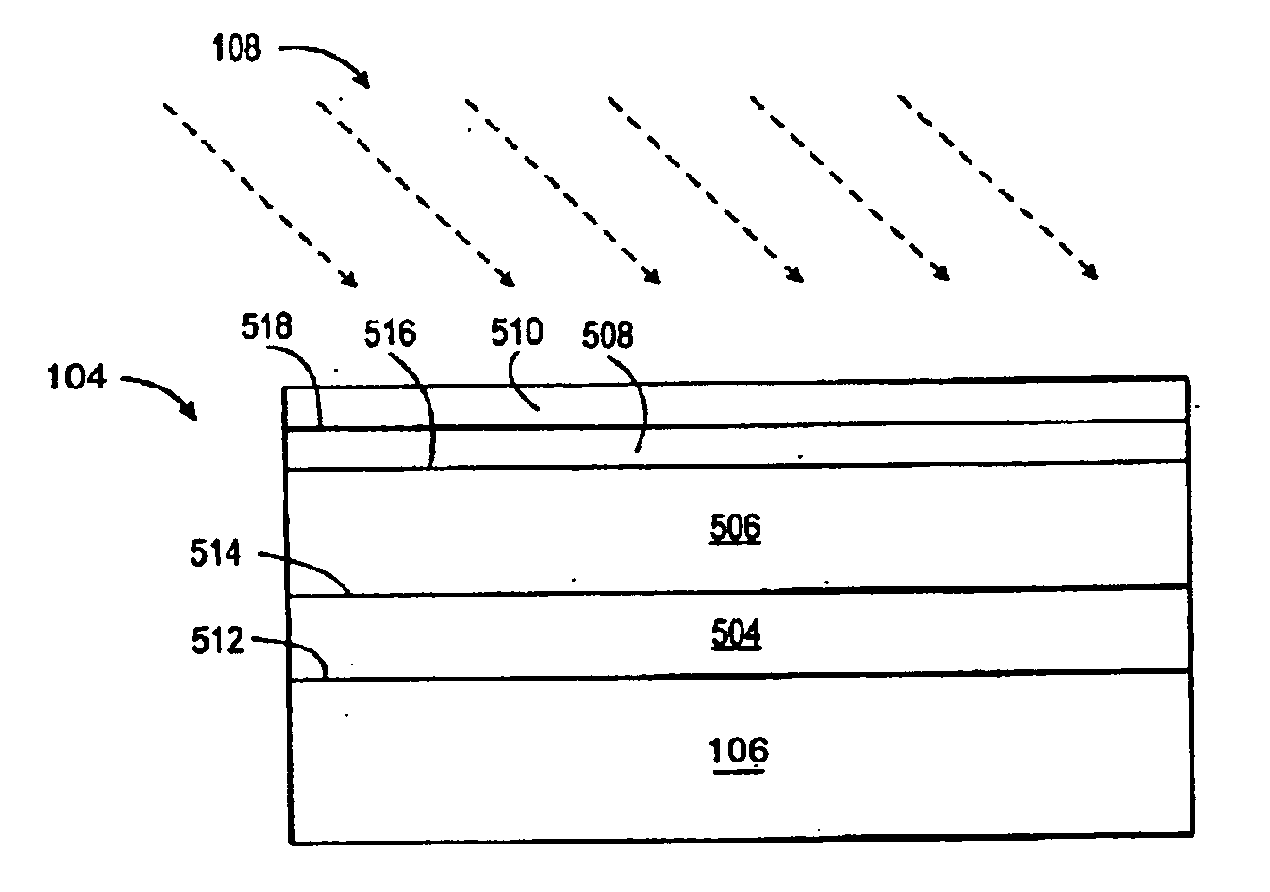

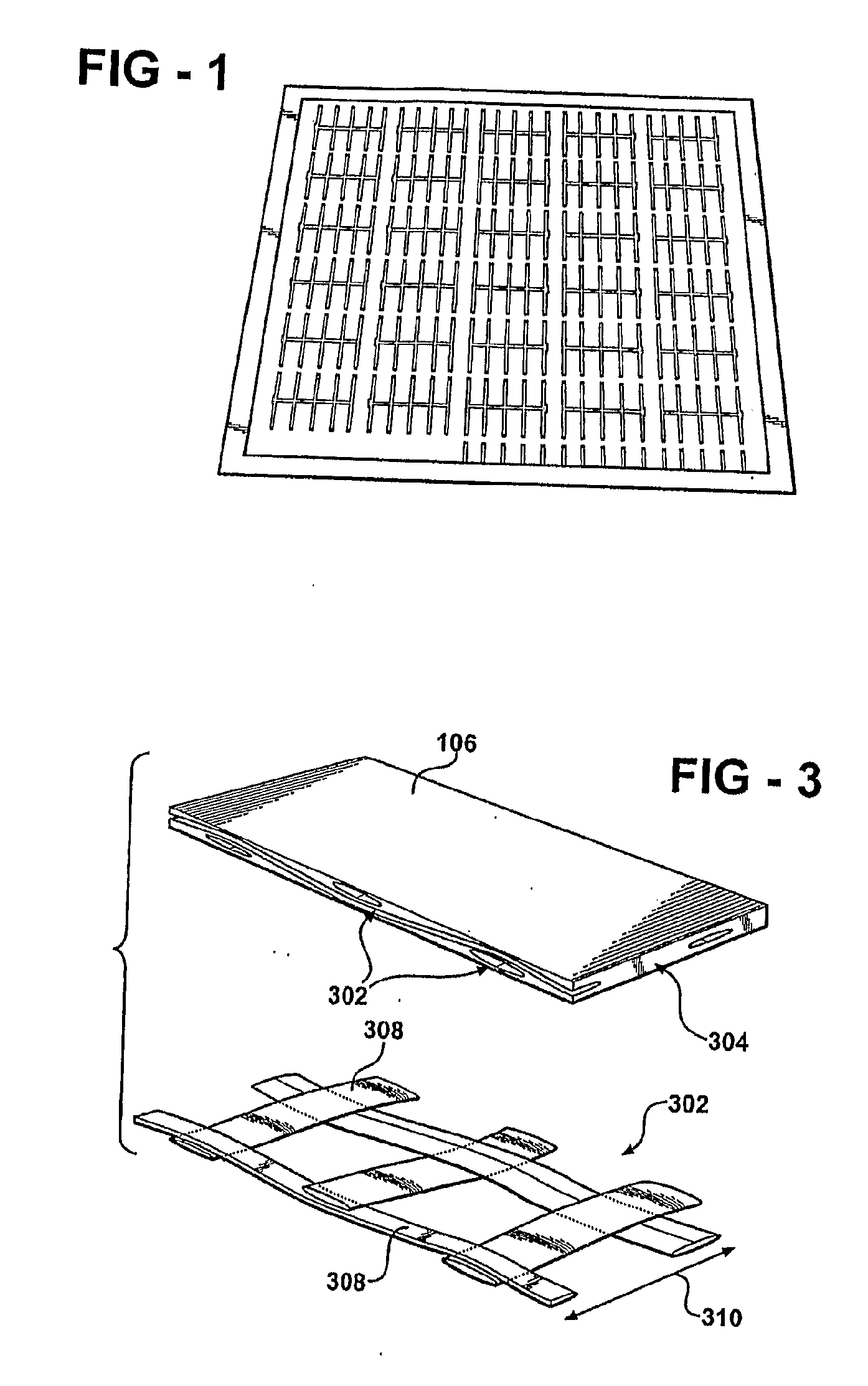

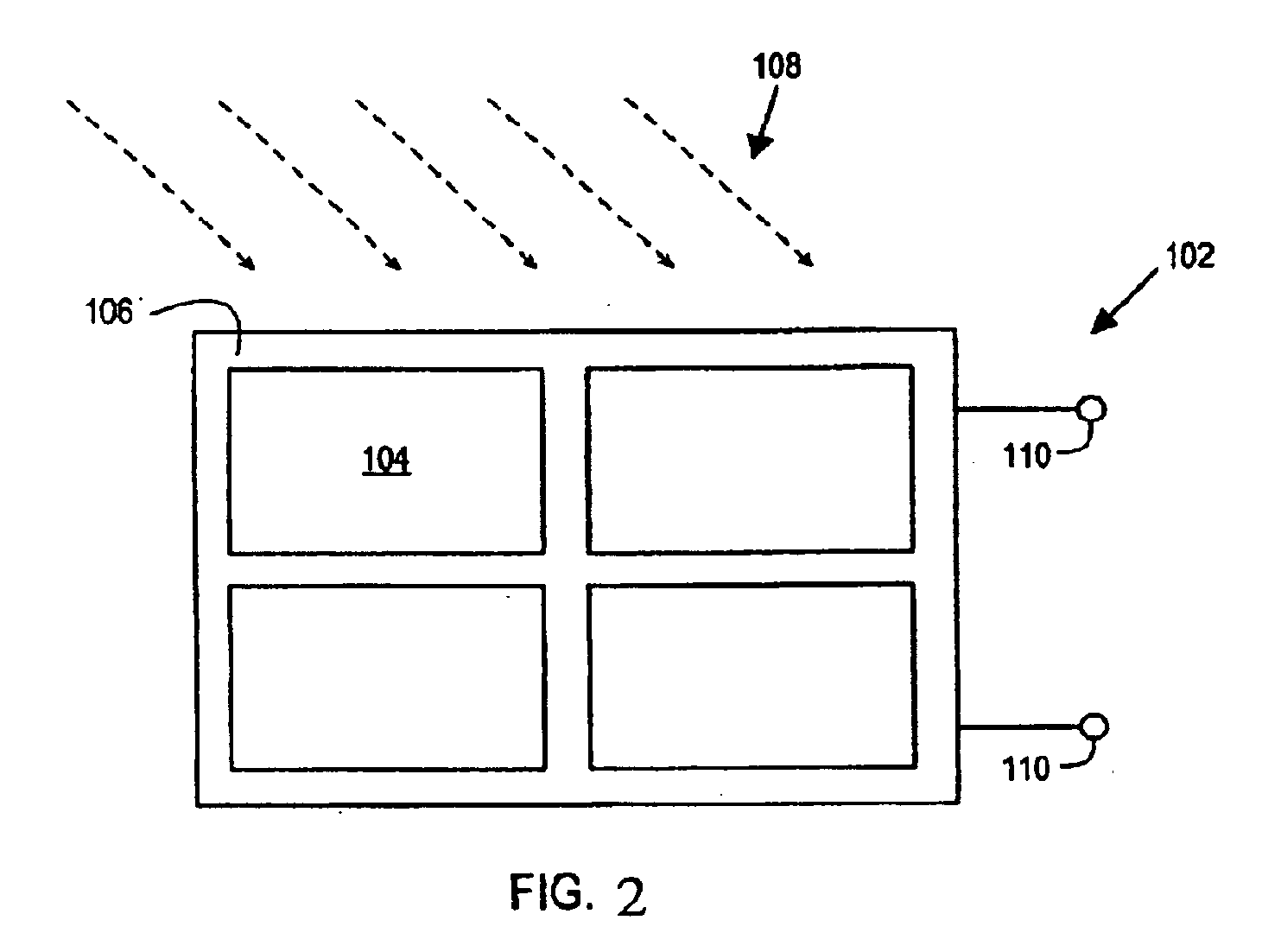

A MOS or CMOS sensor for high performance imaging in broad spectral ranges including portions of the infrared spectral band. These broad spectral ranges may also include portions or all of the visible spectrum, therefore the sensor has both daylight and night vision capabilities. The sensor includes a continuous multi-layer photodiode structure on a many pixel MOS or CMOS readout array where the photodiode structure is chosen to include responses in the near infrared spectral ranges. A preferred embodiment incorporates a microcrystalline copper indium diselenide / cadmium sulfide photodiode structure on a CMOS readout array. An alternate preferred embodiment incorporates a microcrystalline silicon germanium photodiode structure on a CMOS readout array. Each of these embodiments provides night vision with image performance that greatly surpasses the GEN III night vision technology in terms of enhanced sensitivity, pixel size and pixel count. Further advantages of the invention include low electrical bias voltages, low power consumption, compact packaging, and radiation hardness. In special preferred embodiments CMOS stitching technology is used to provide multi-million pixel focal plane array sensors. One embodiments of the invention made without stitching is a two-million pixel sensor. Other preferred embodiments available using stitching techniques include sensors with 250 million (or more) pixels fabricated on a single wafer. A particular application of these very high pixel count sensors is as a focal plane array for a rapid beam steering telescope in a low earth orbit satellite useful for tracking over a 1500-meter wide track with a resolution of 0.3 meter.

Owner:C PHOCUS

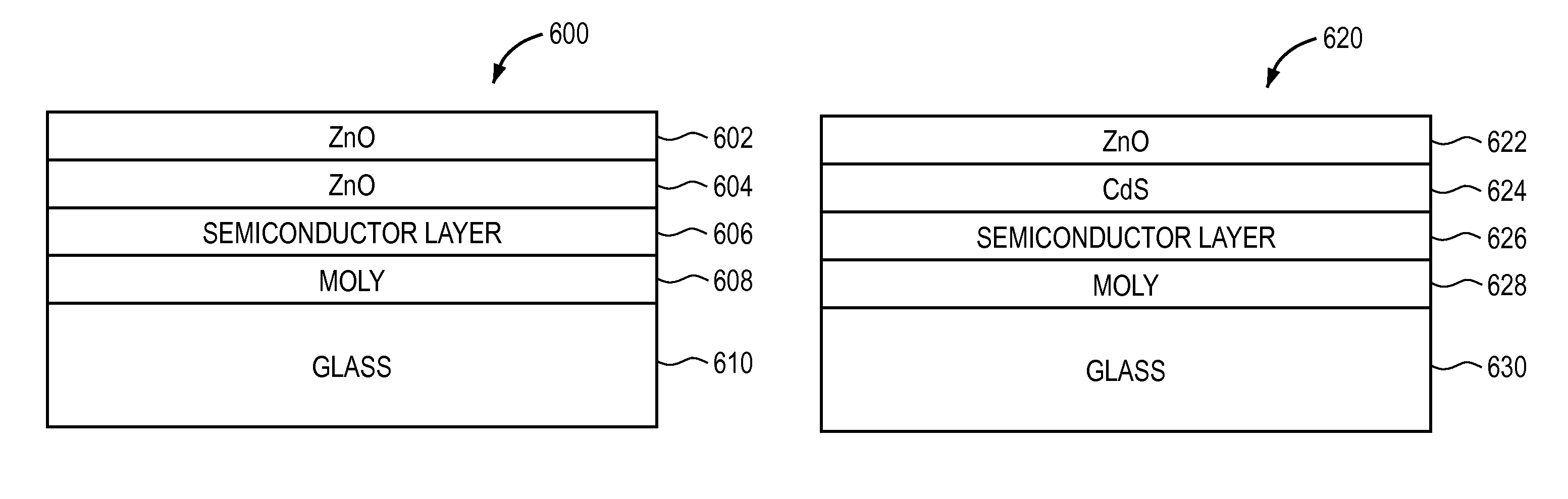

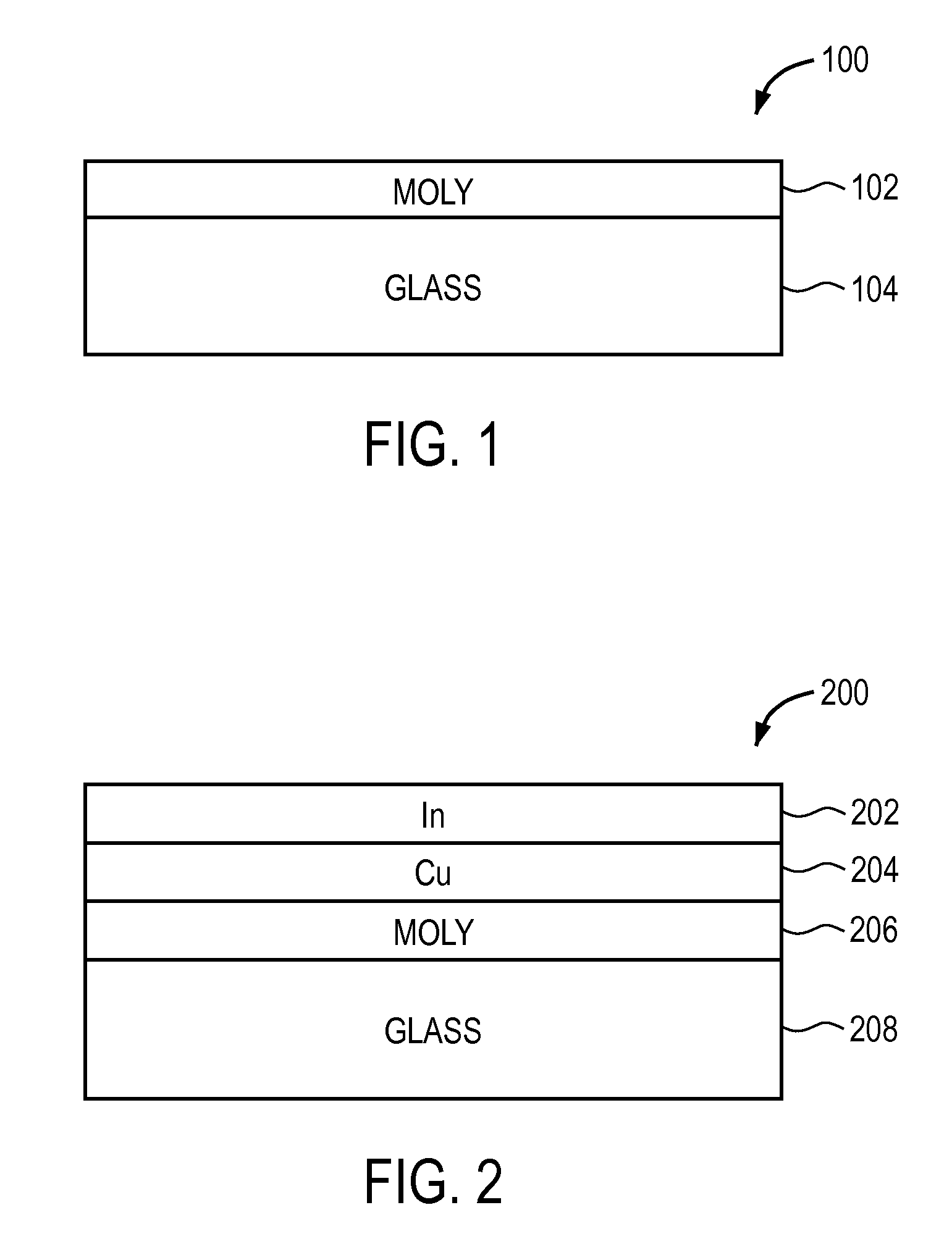

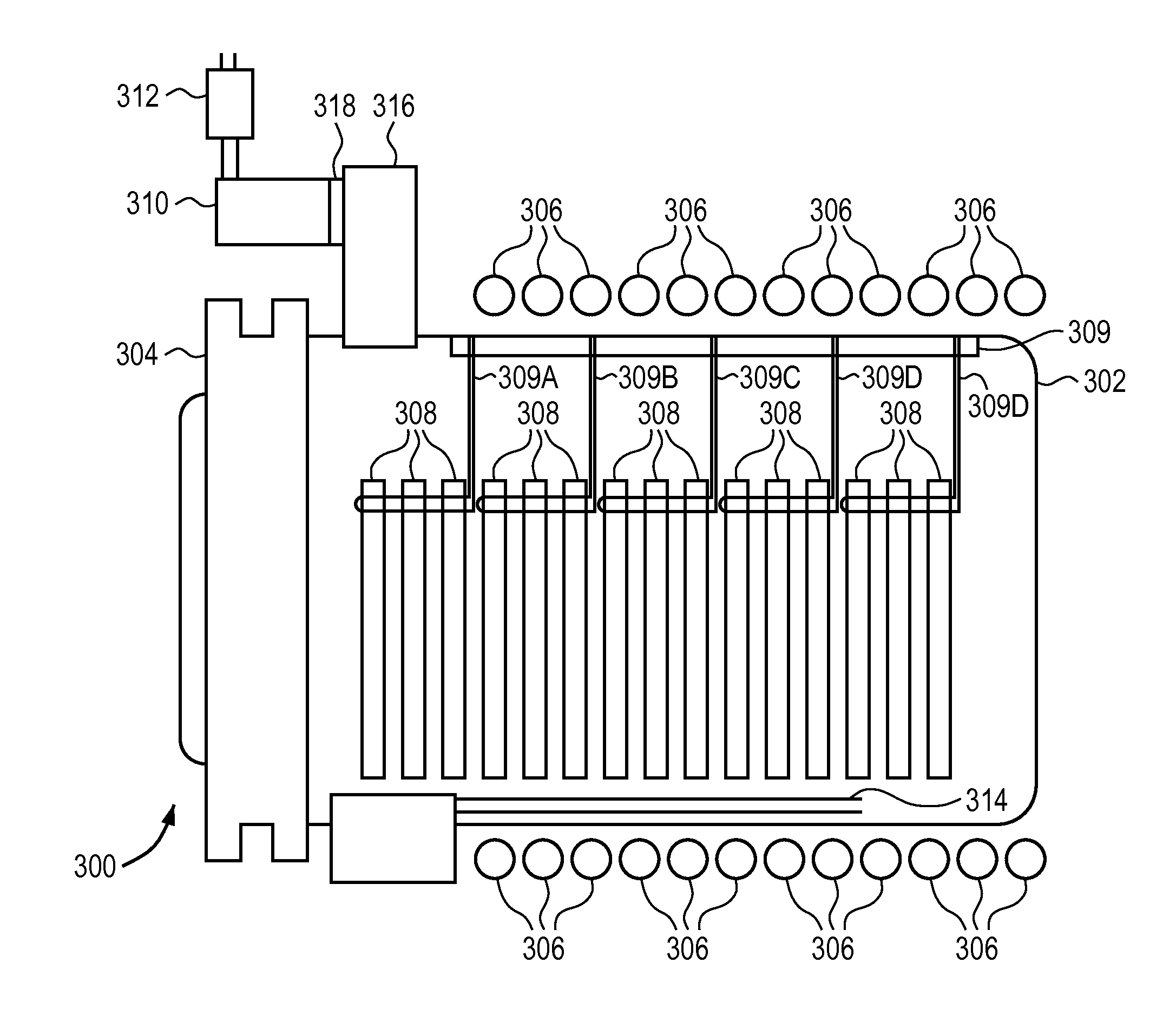

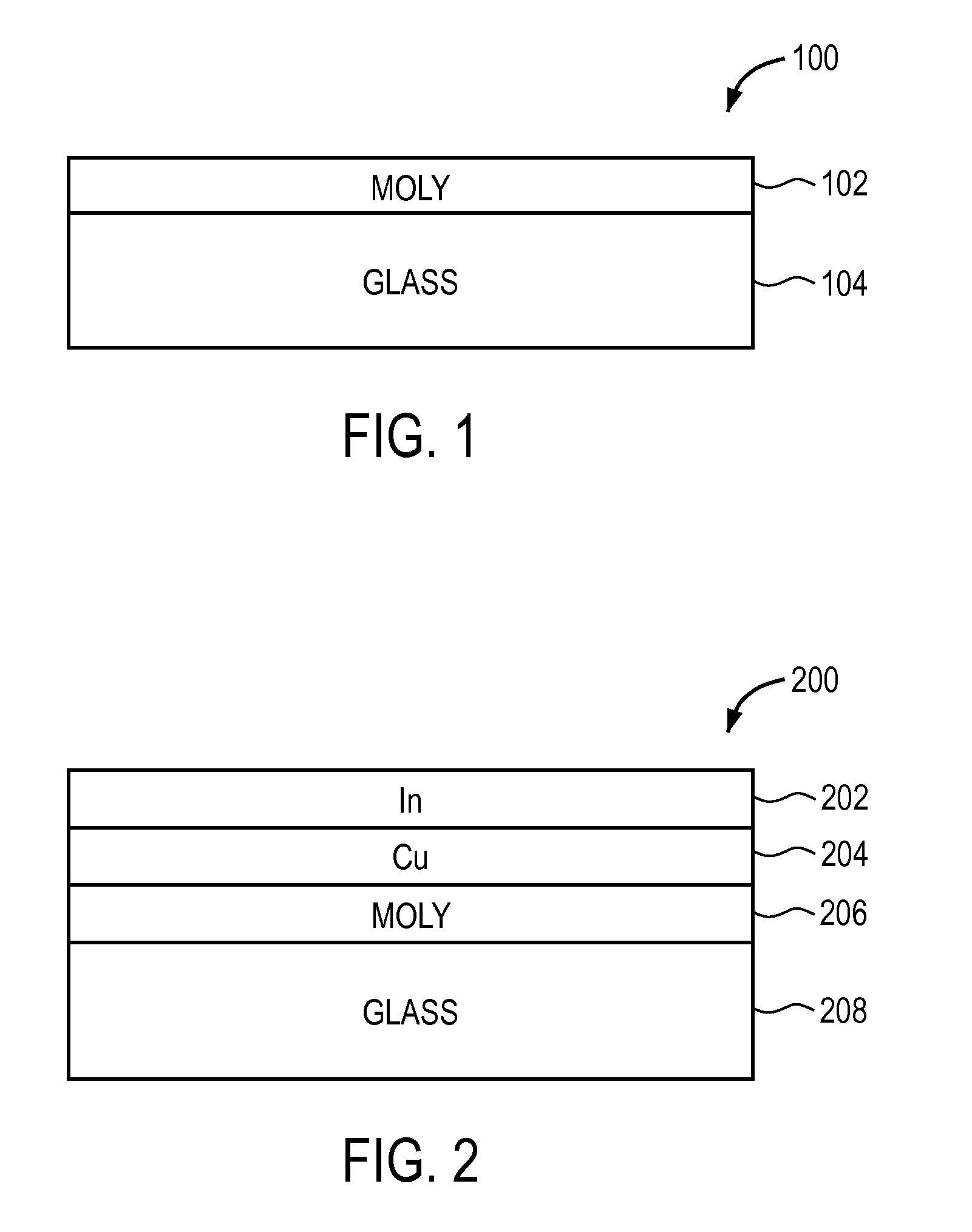

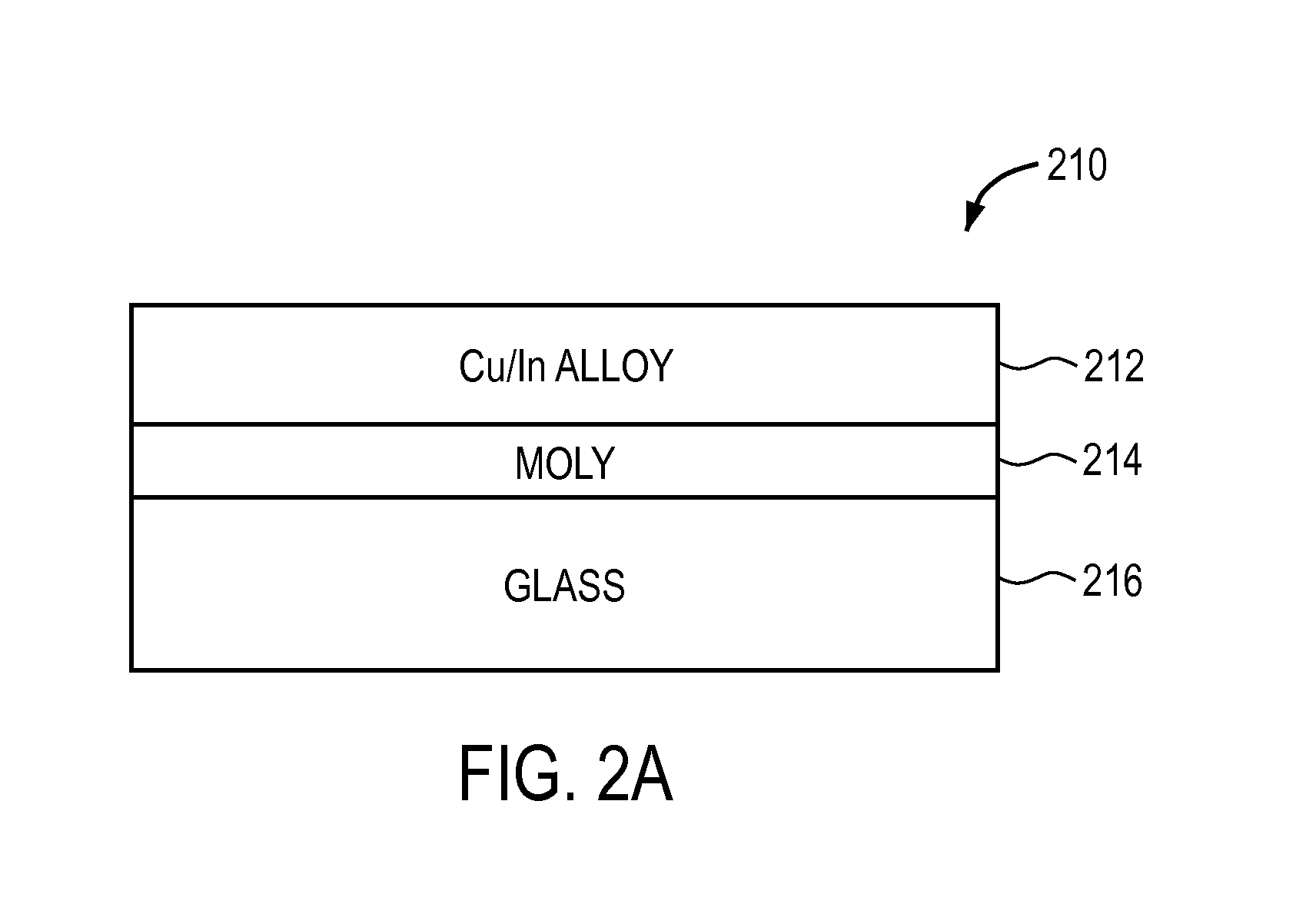

Thermal management and method for large scale processing of CIS and/or CIGS based thin films overlying glass substrates

InactiveUS7910399B1Implemented cost-effectivelyMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

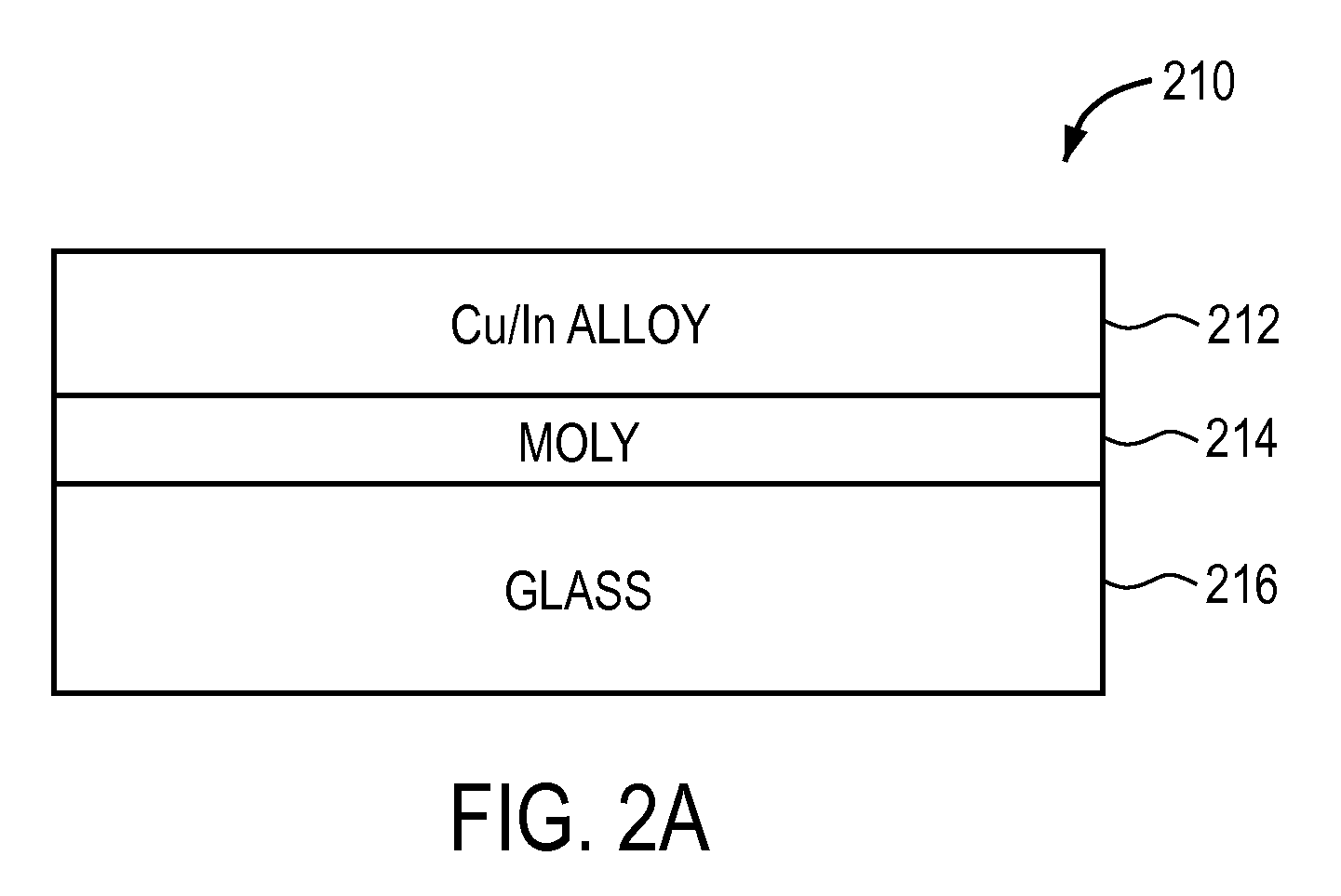

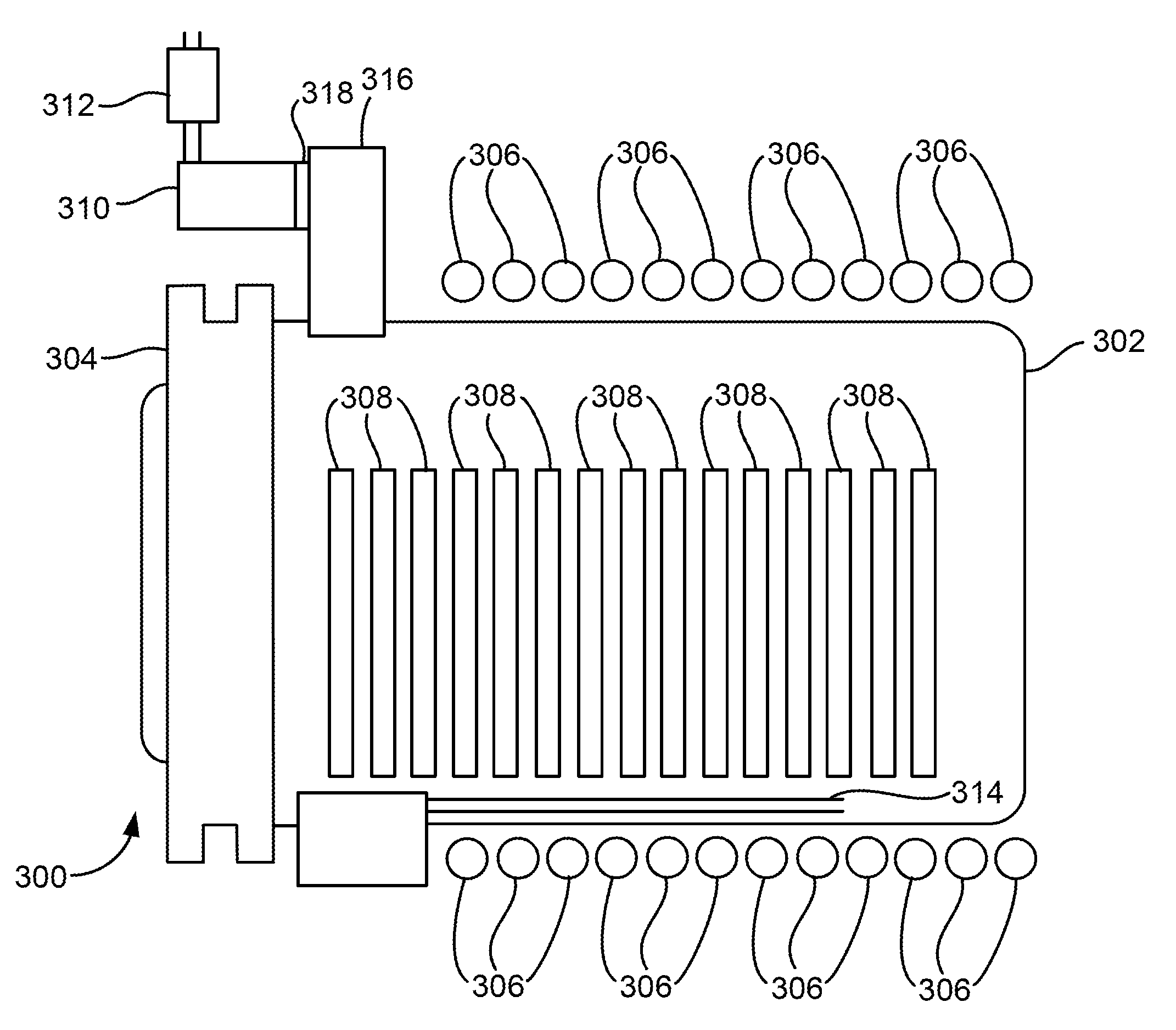

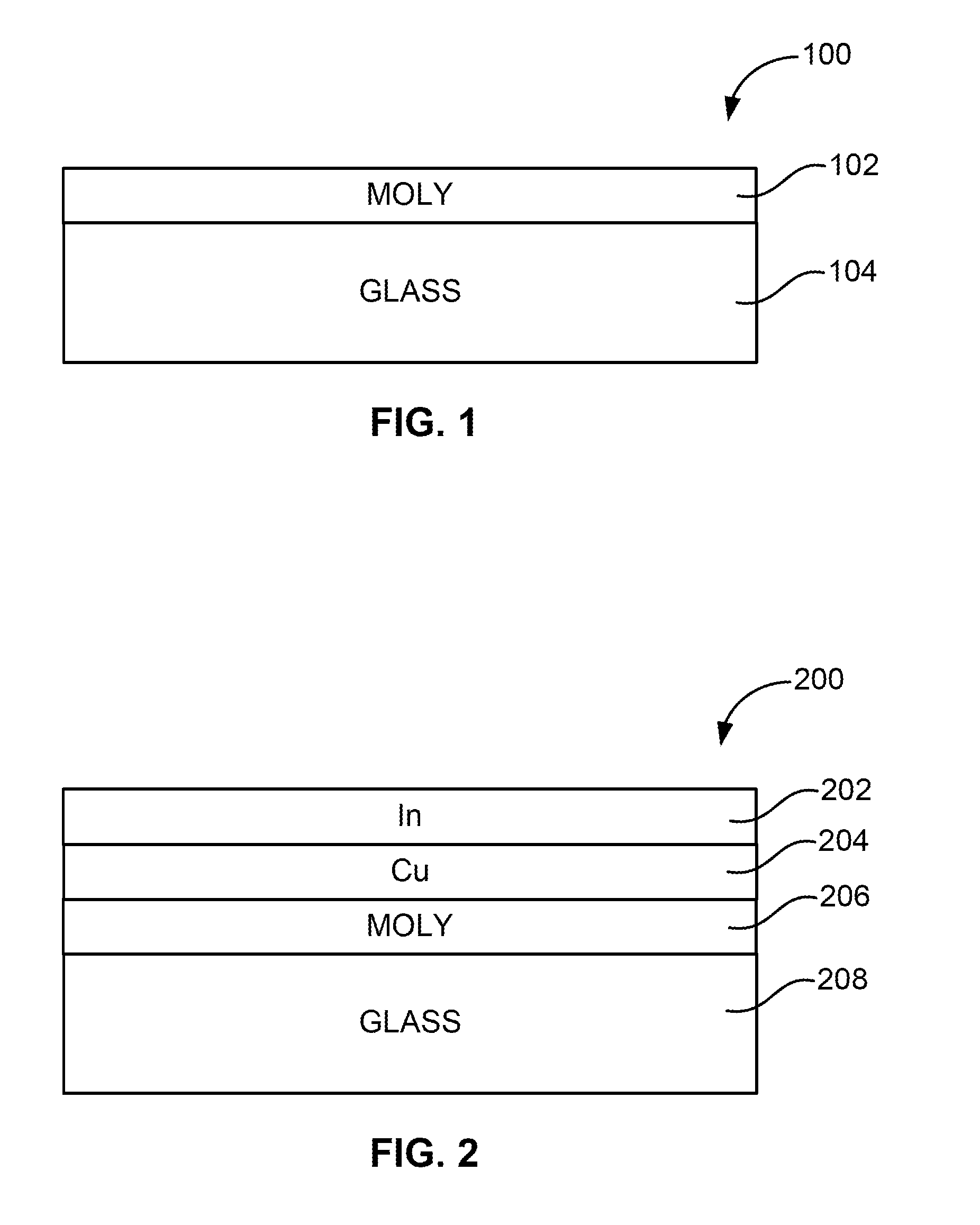

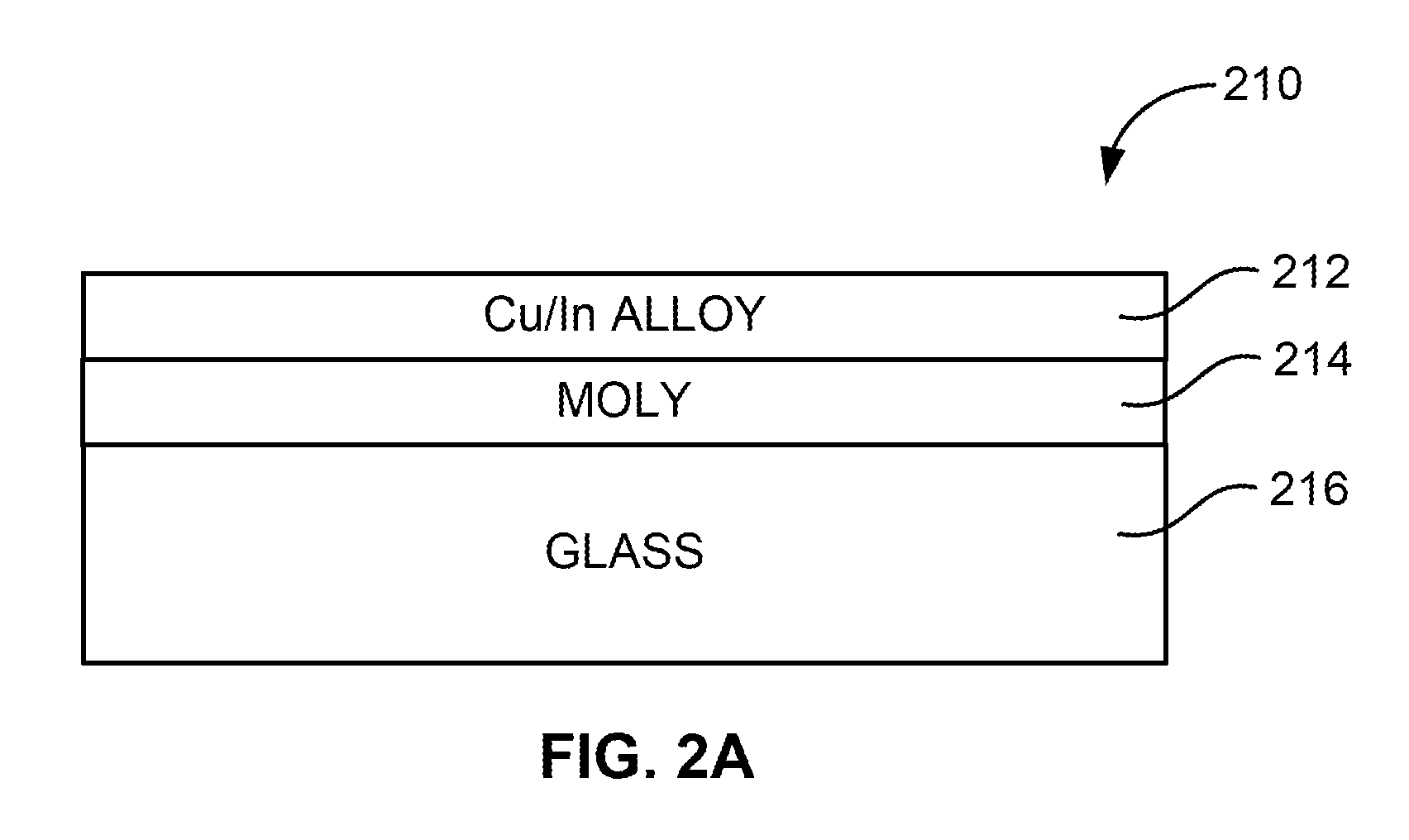

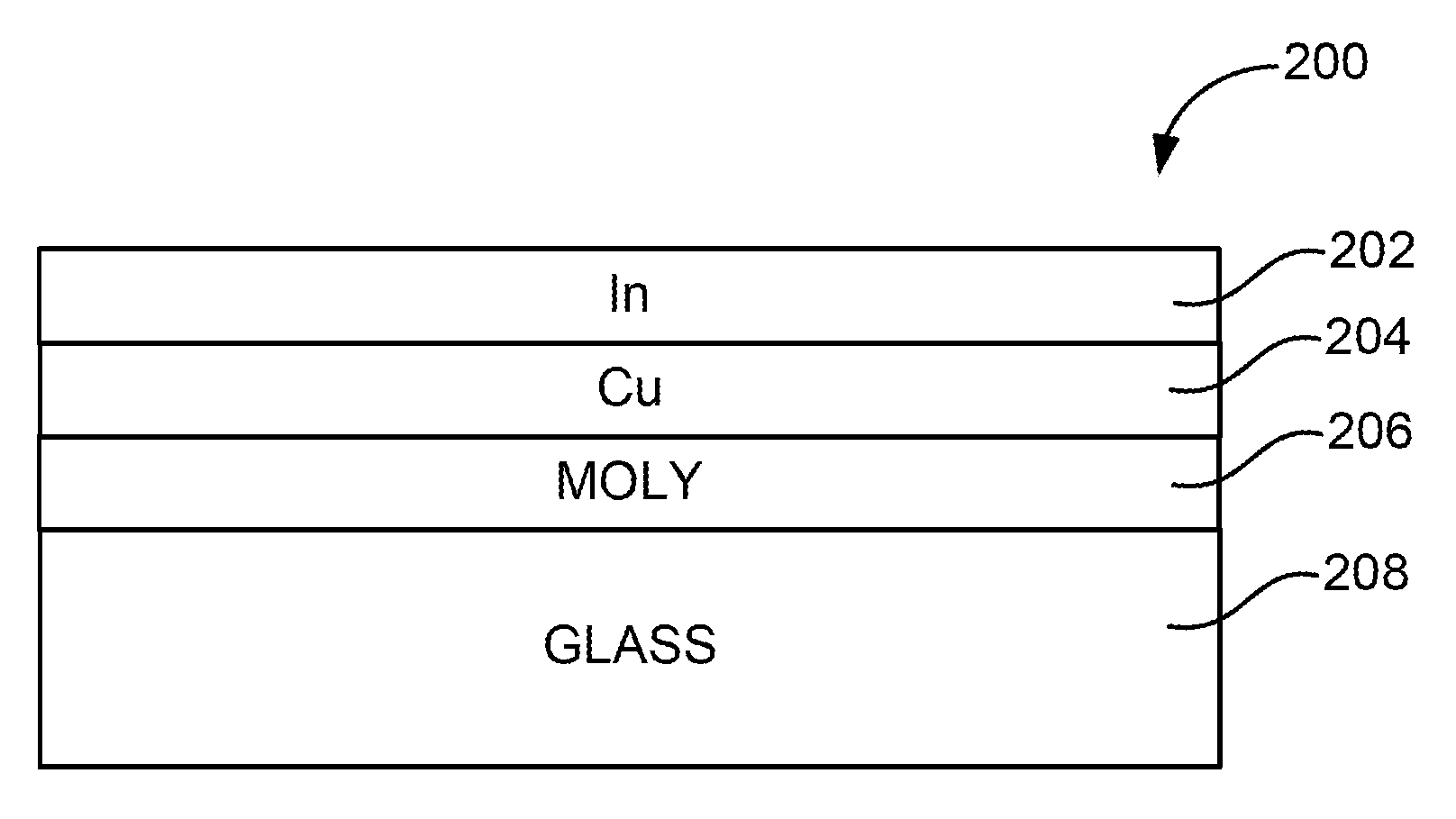

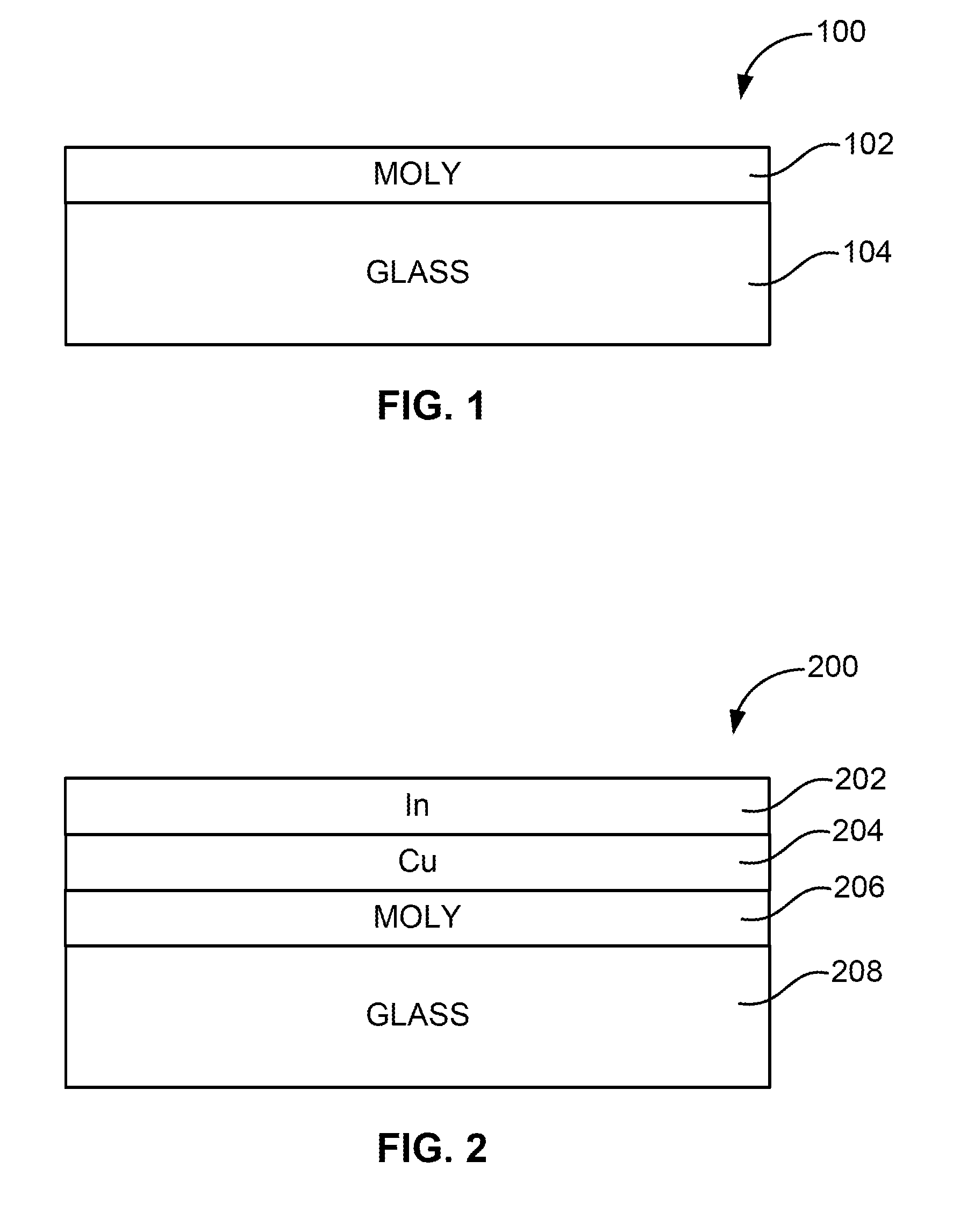

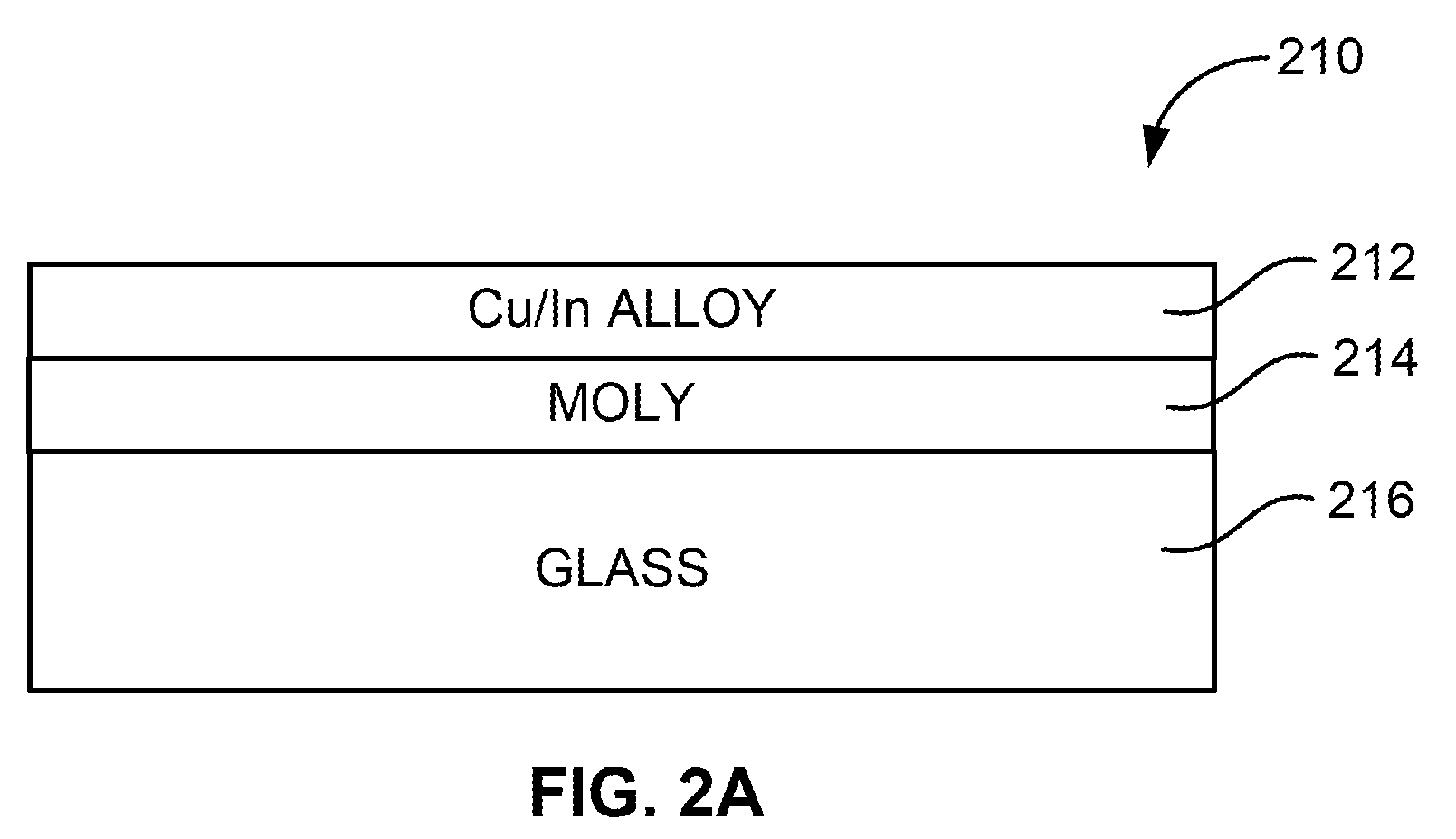

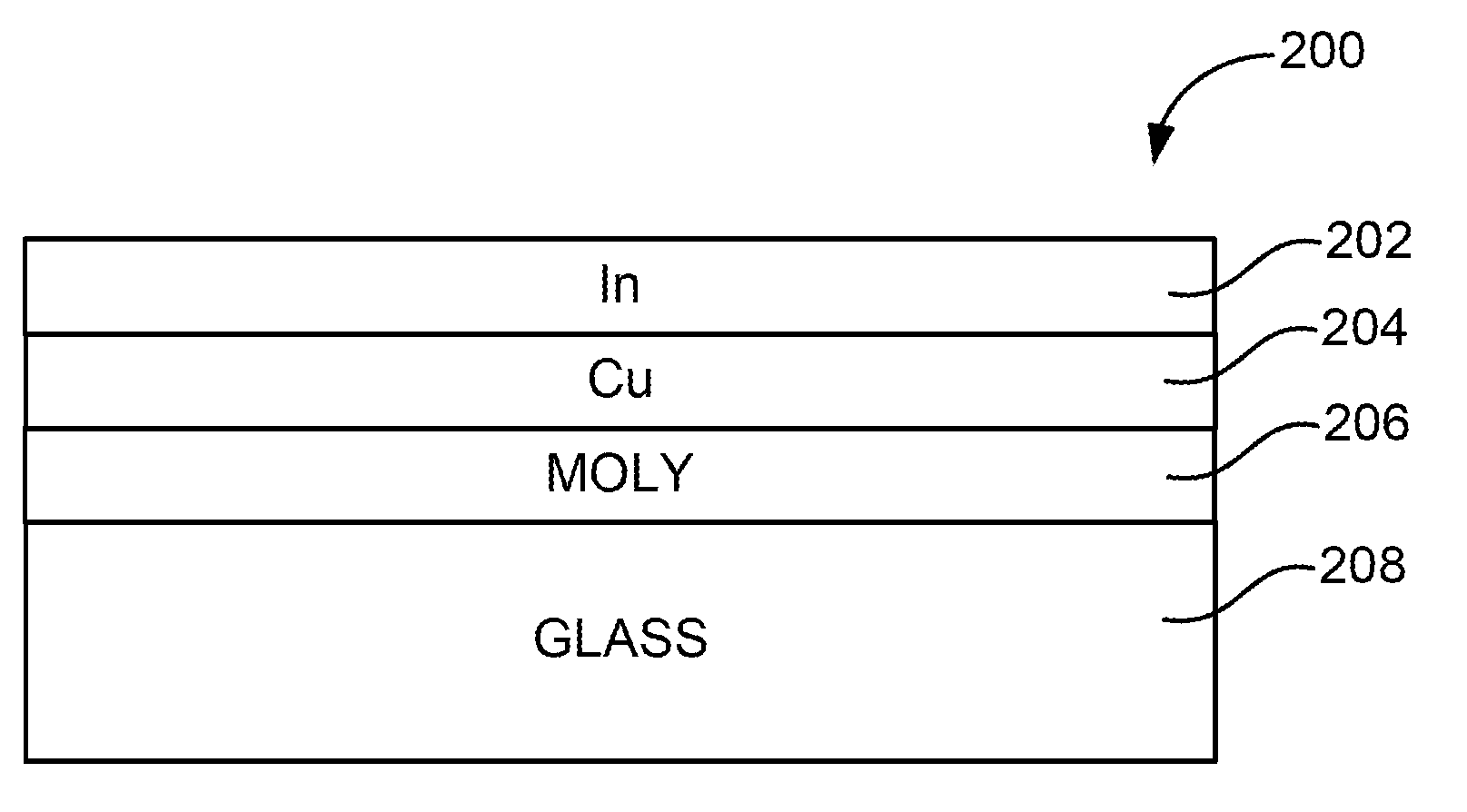

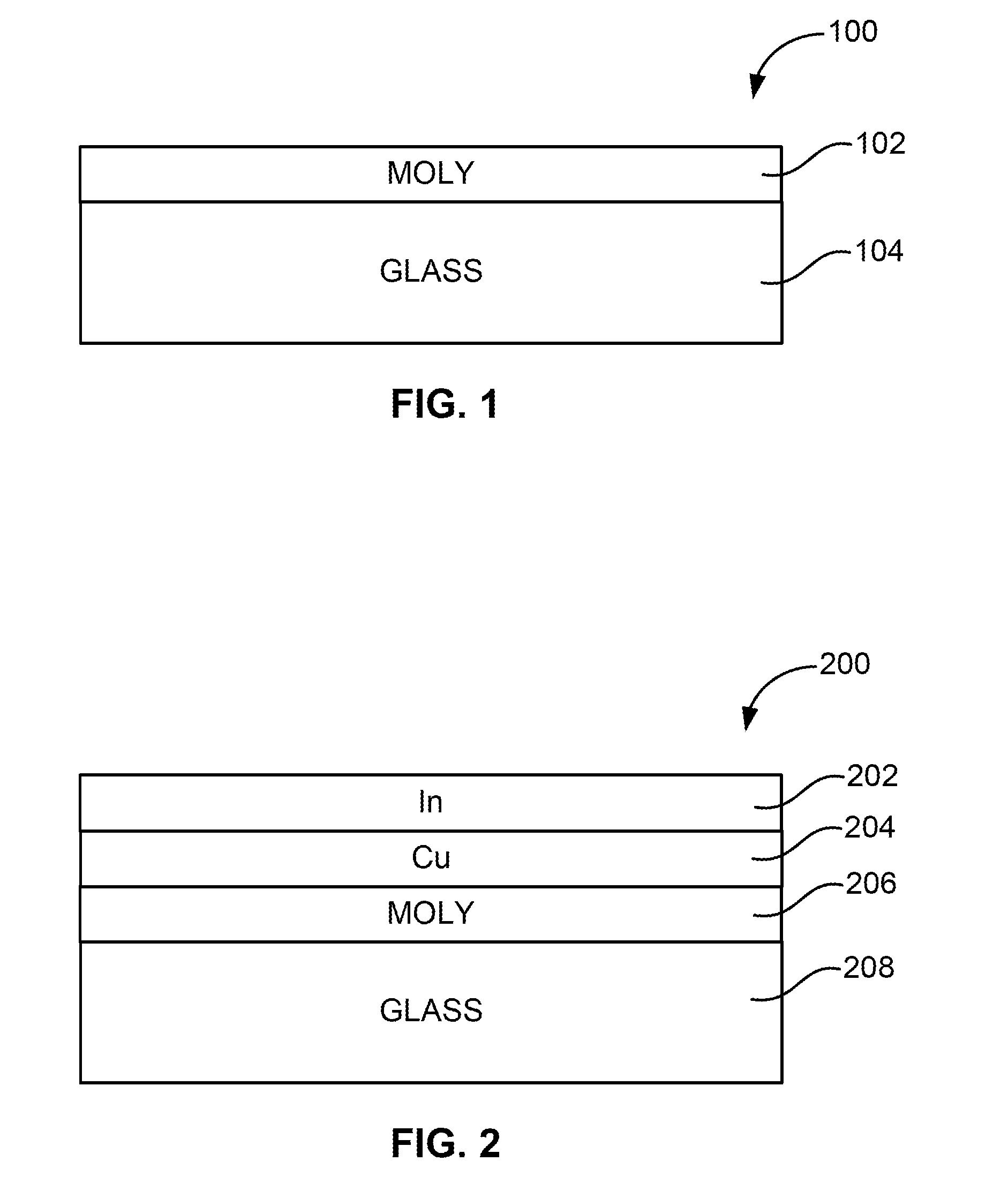

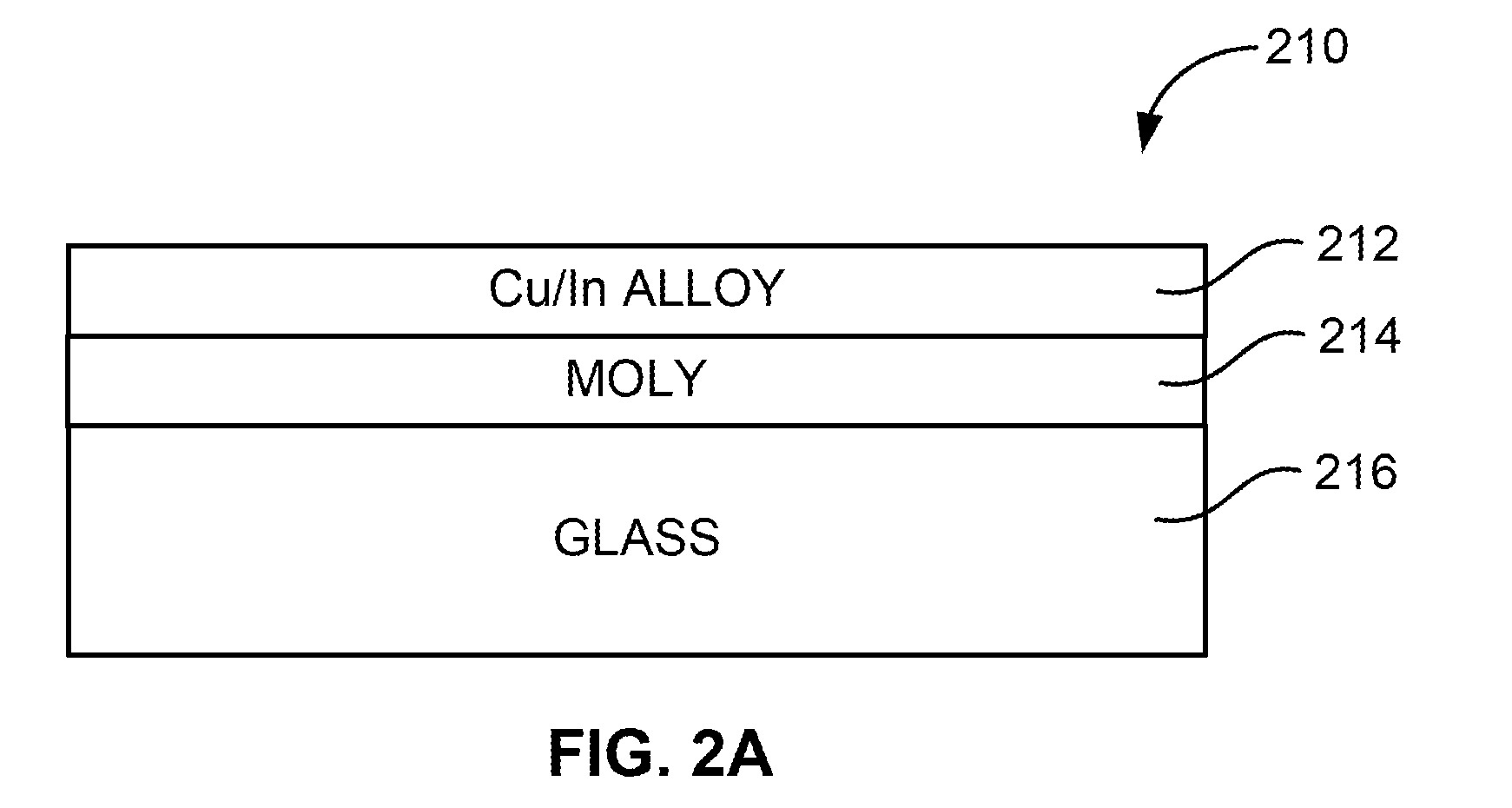

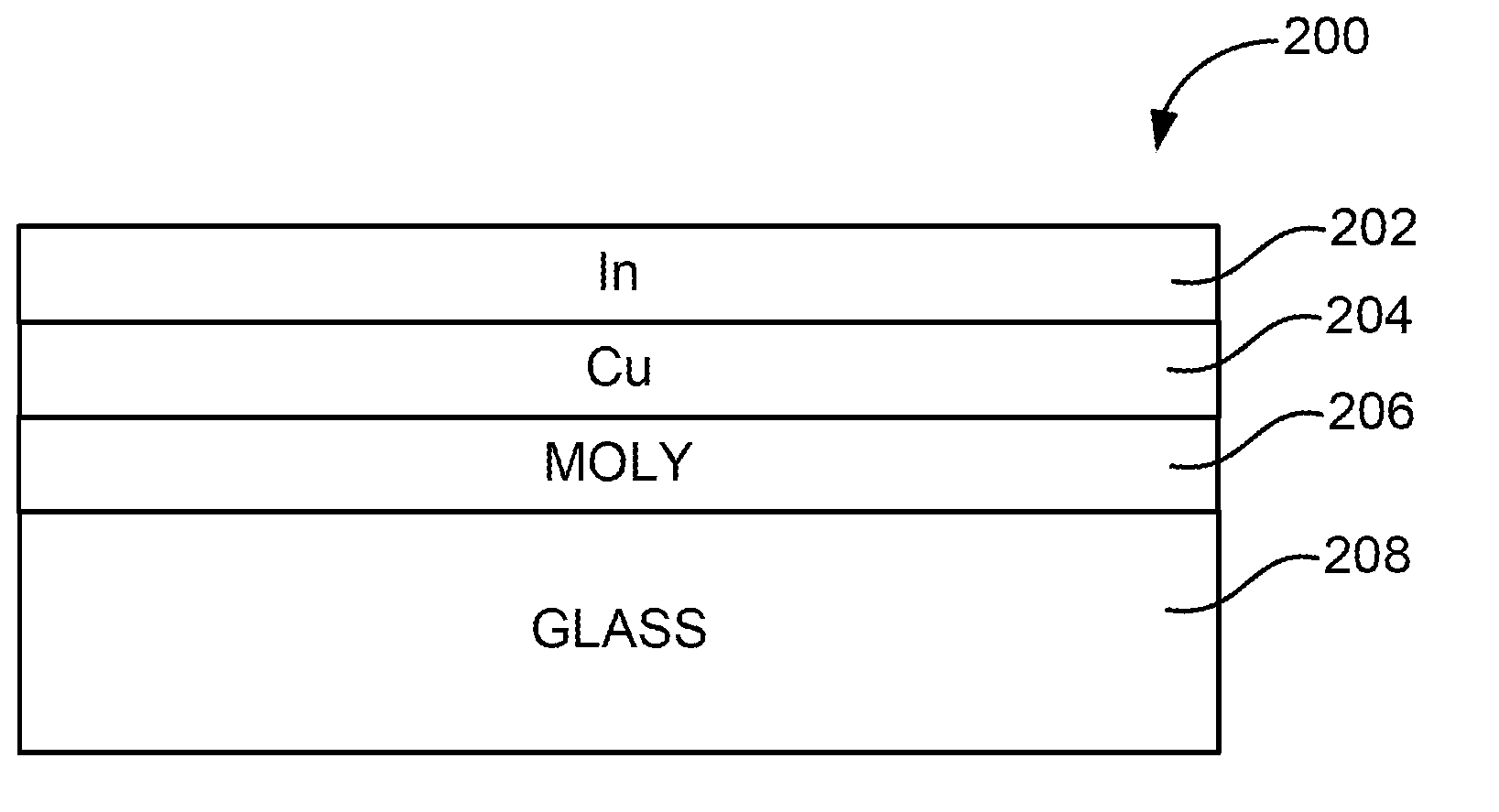

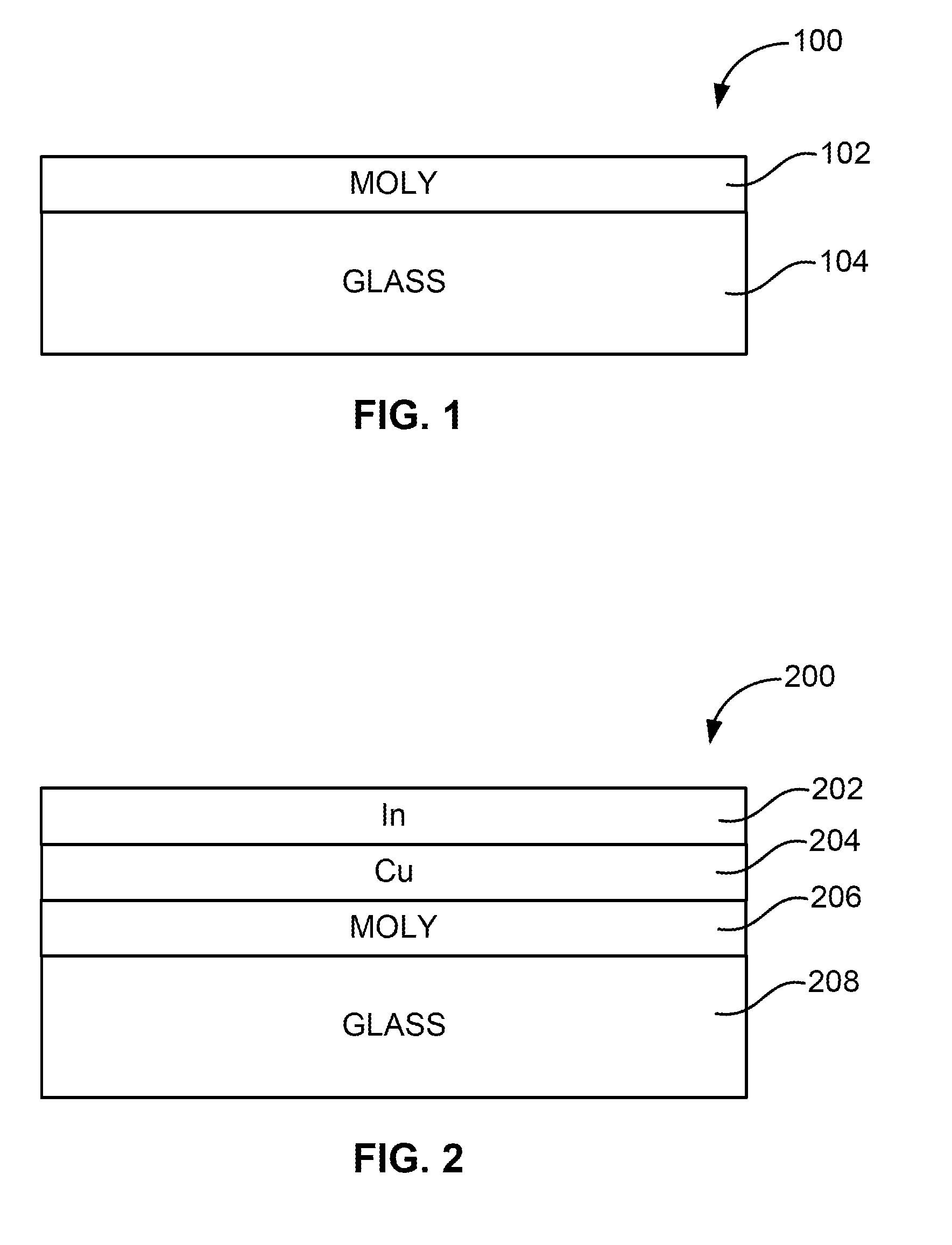

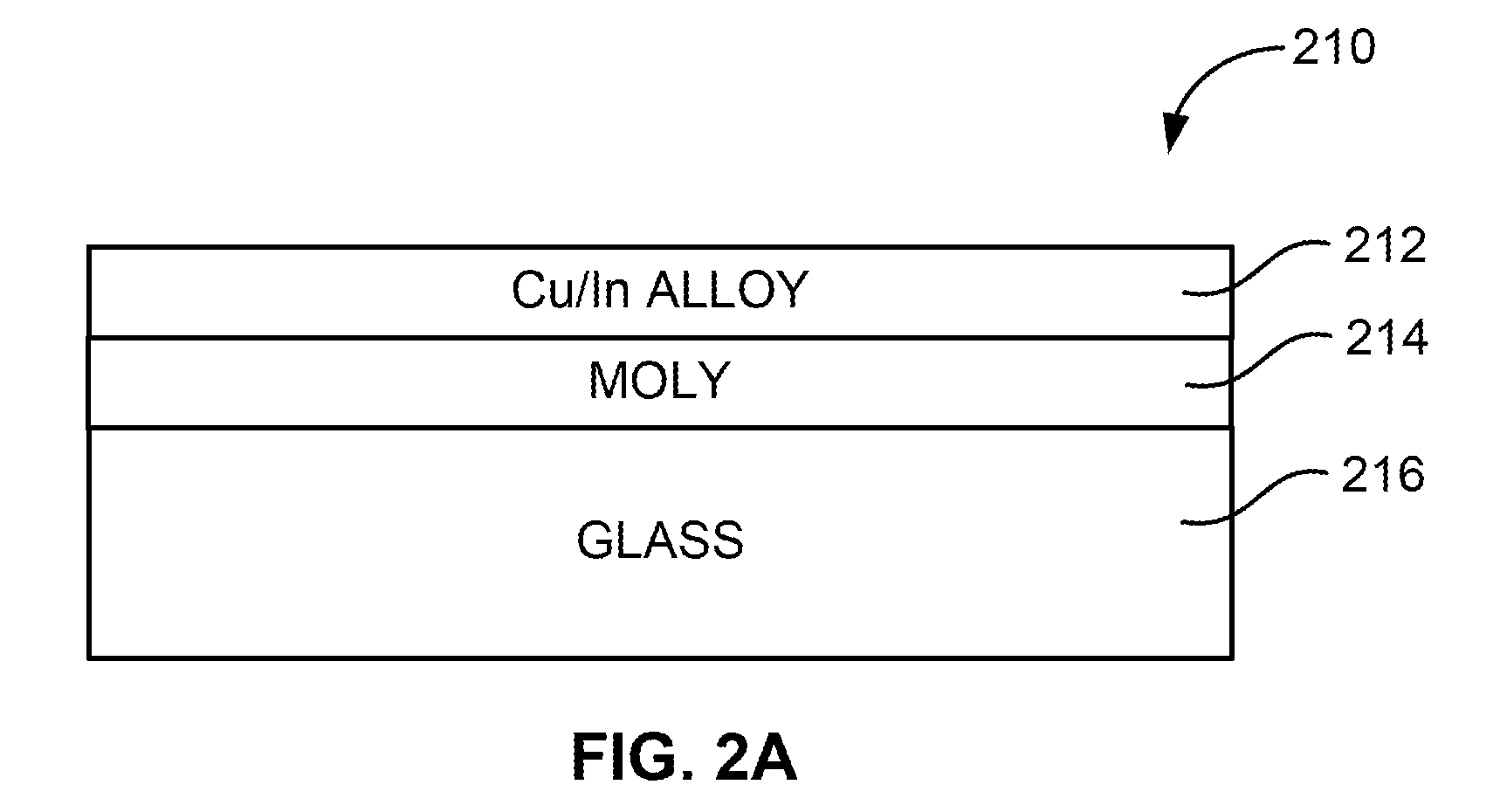

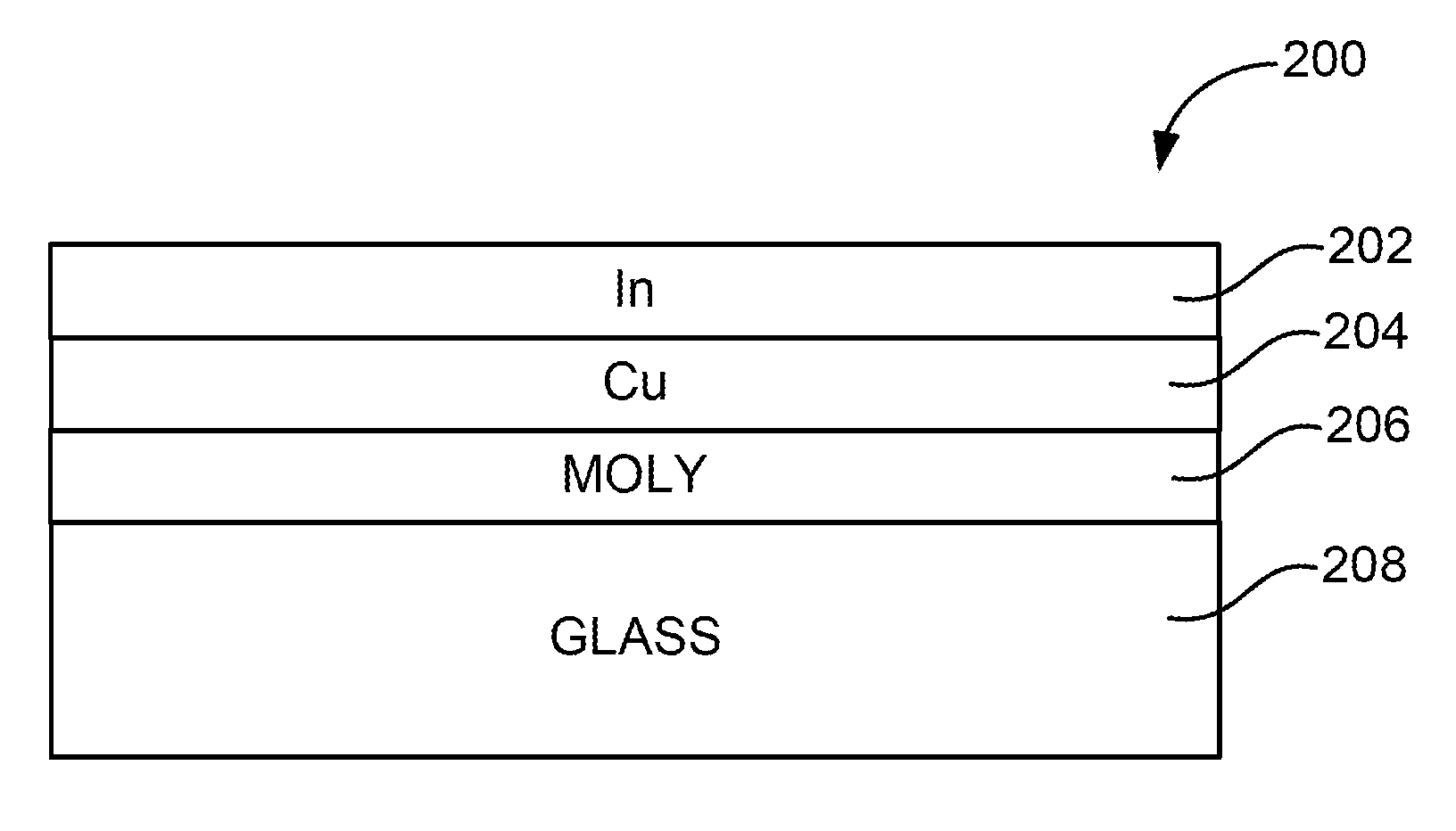

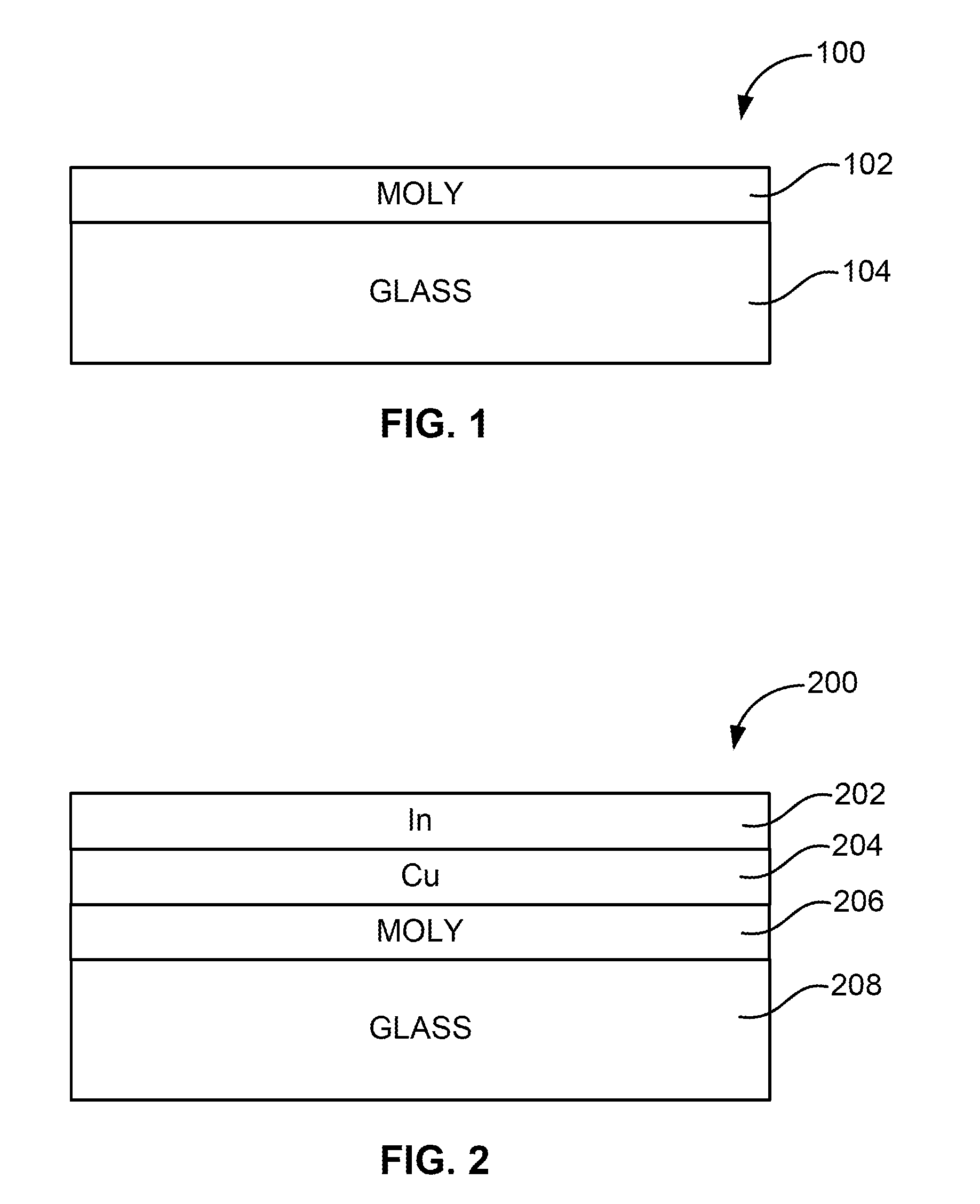

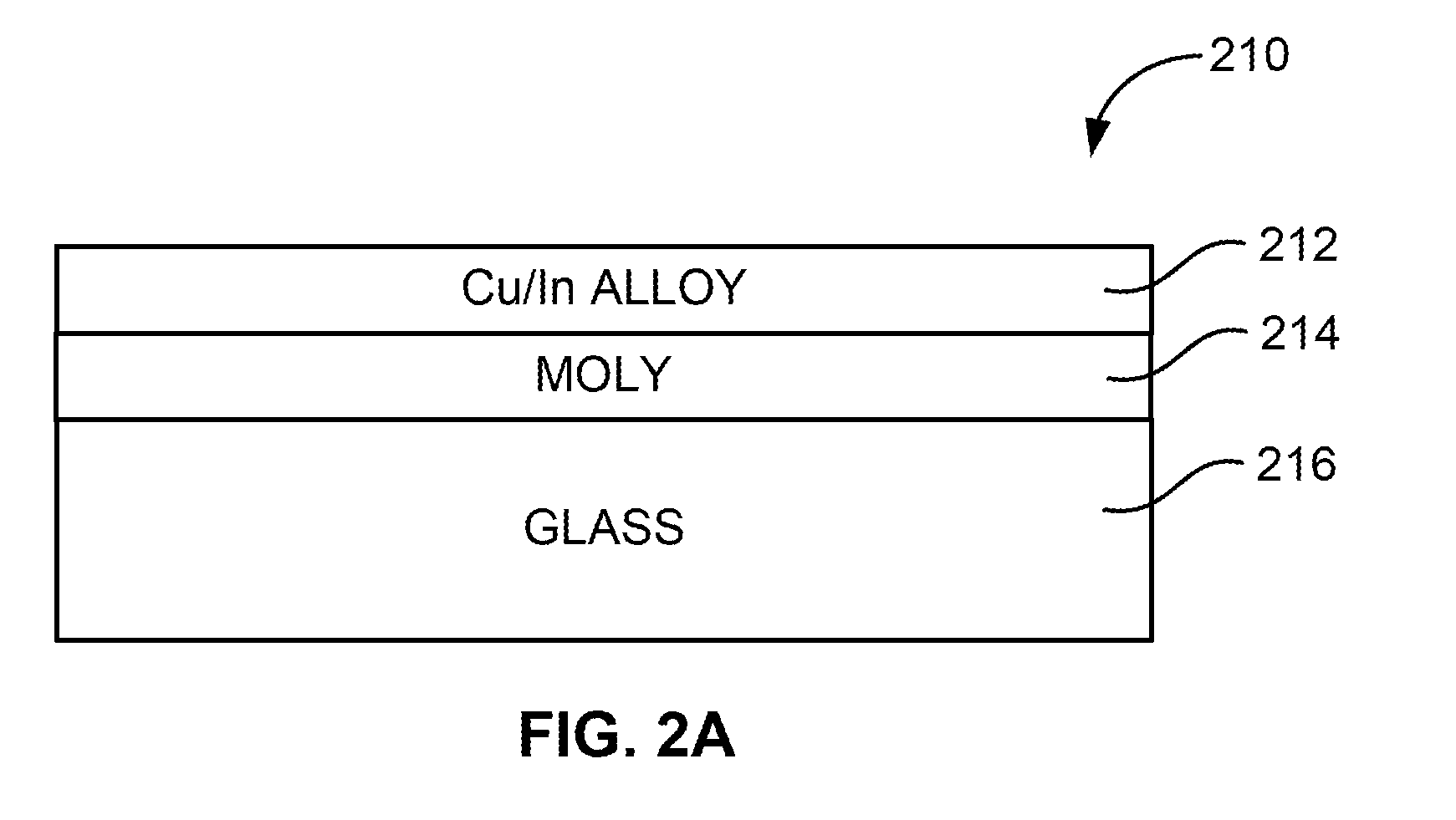

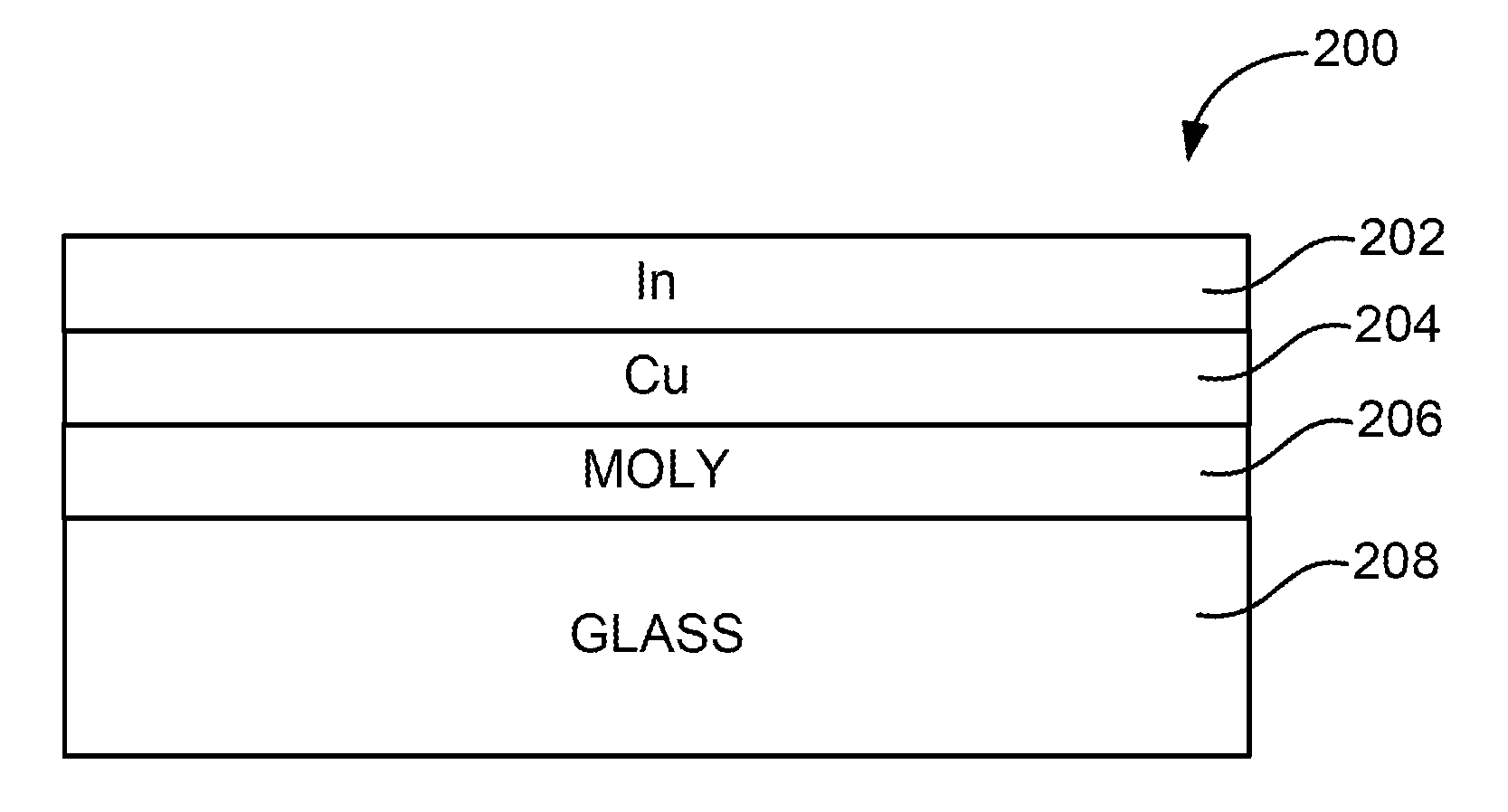

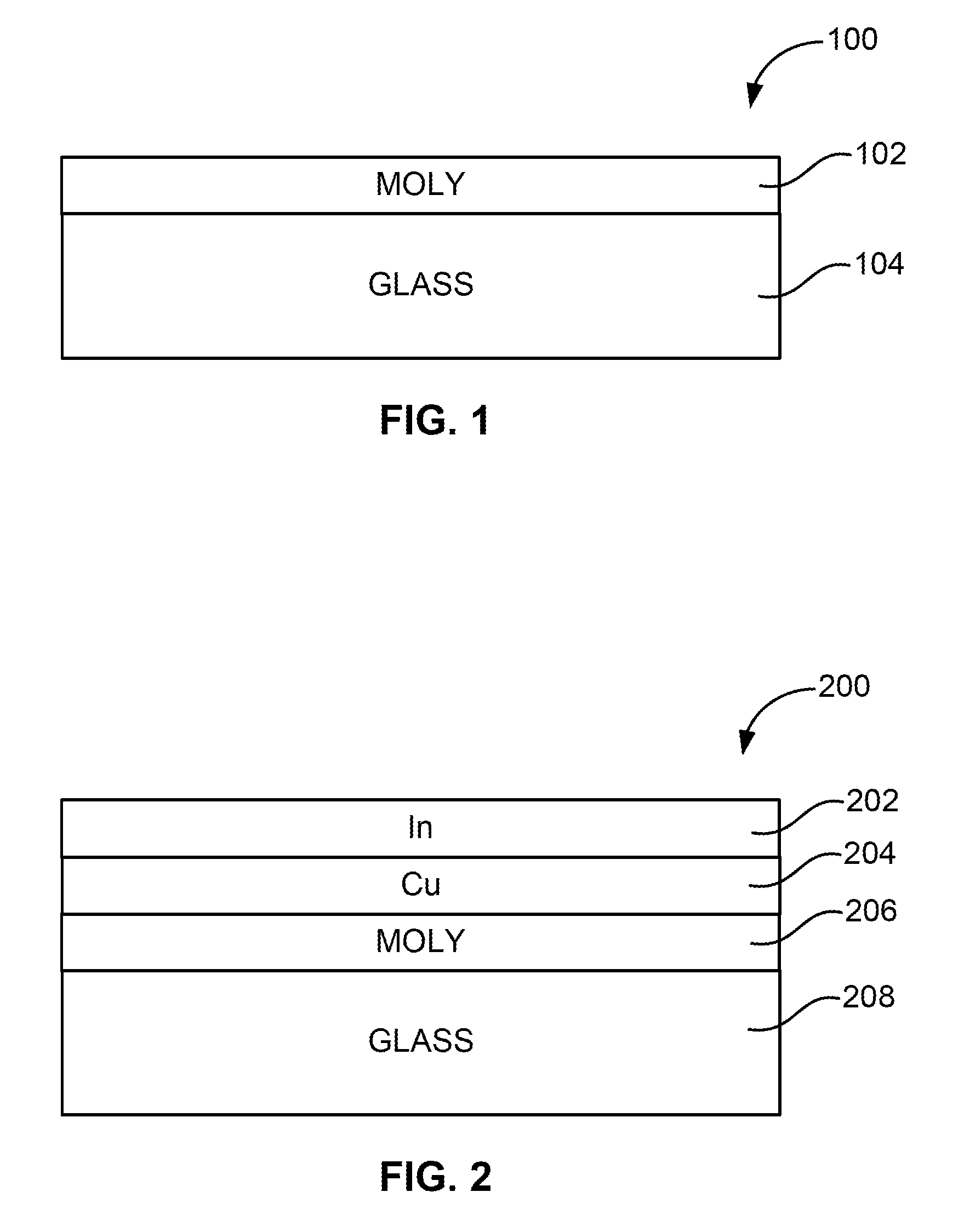

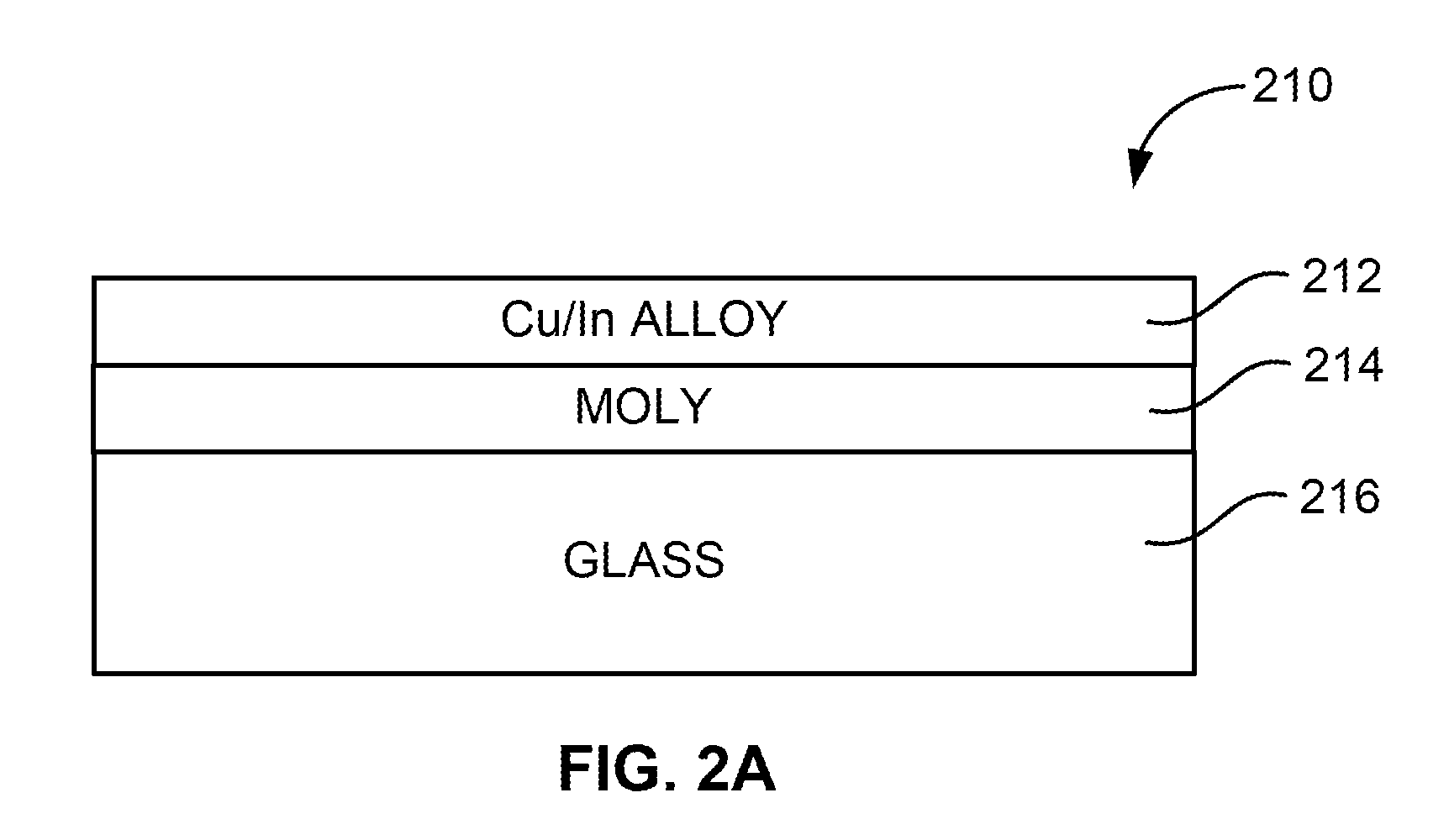

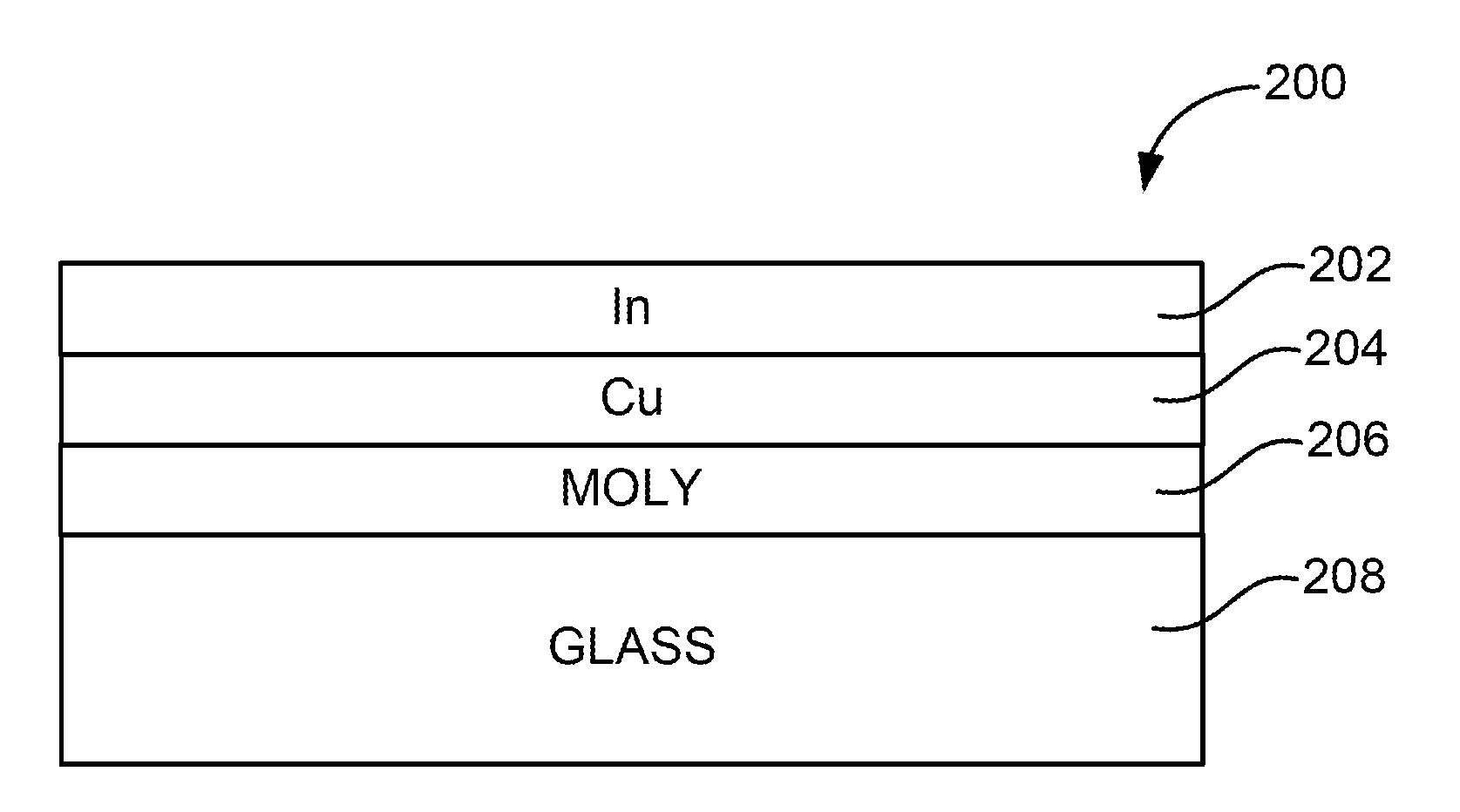

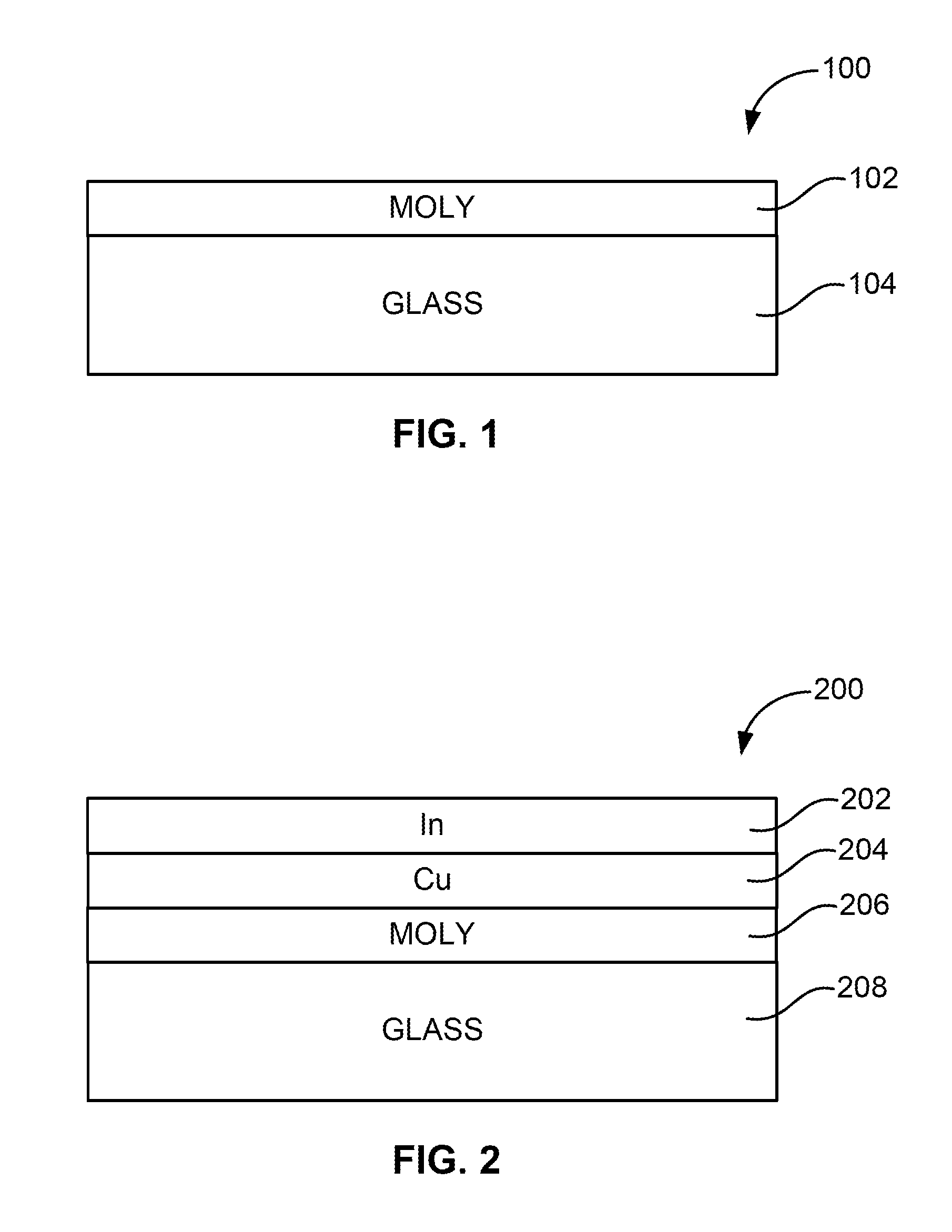

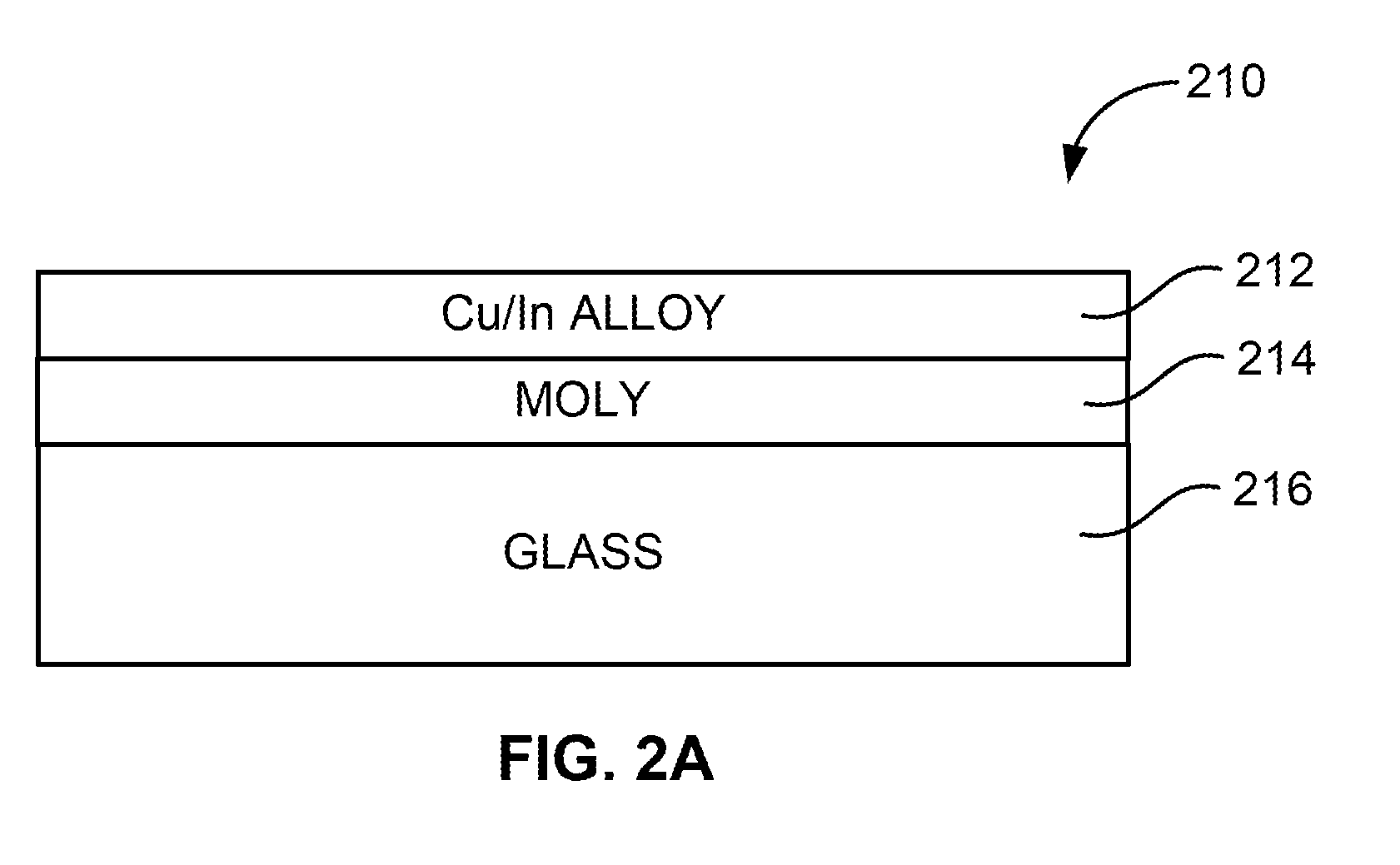

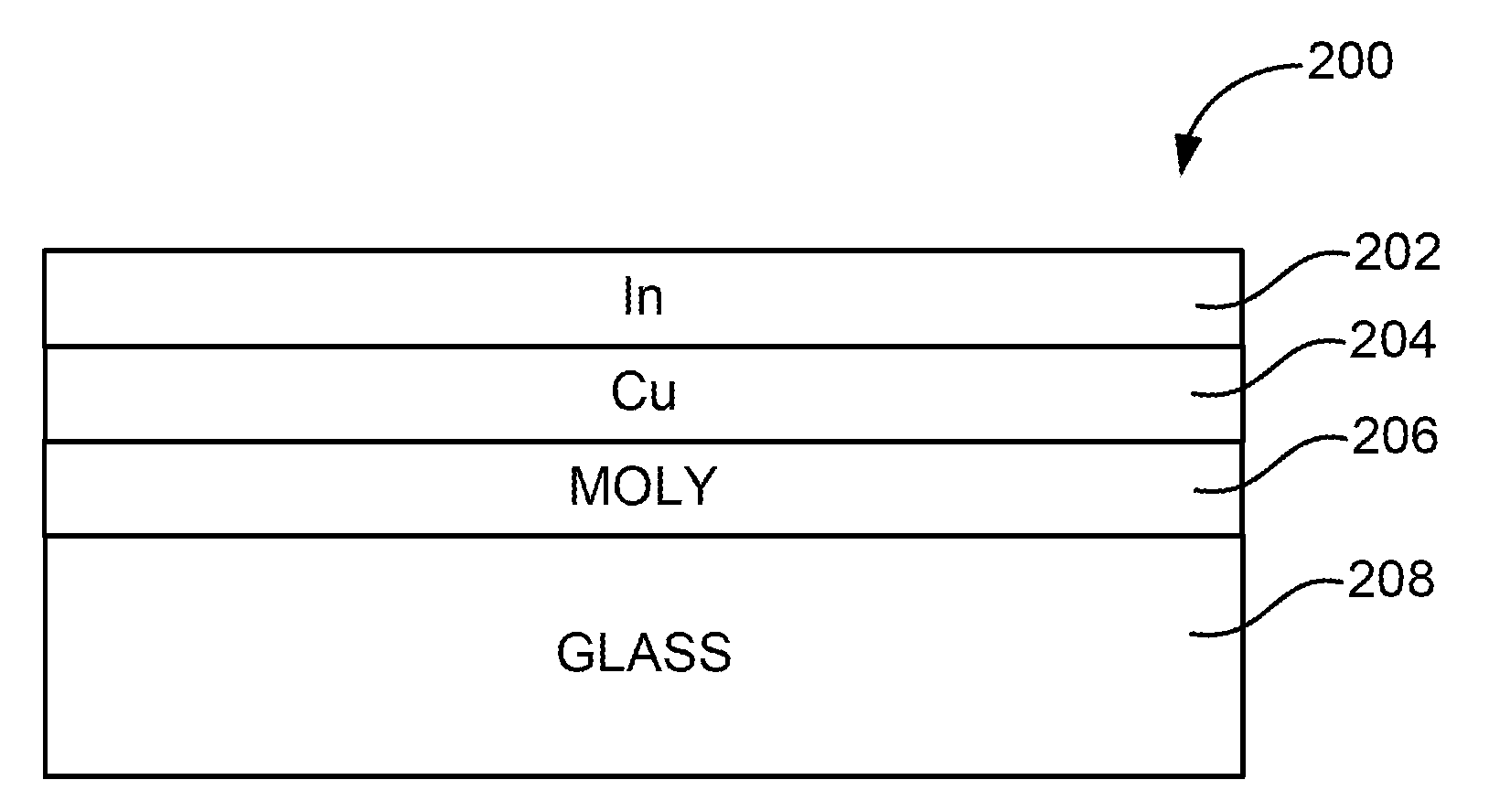

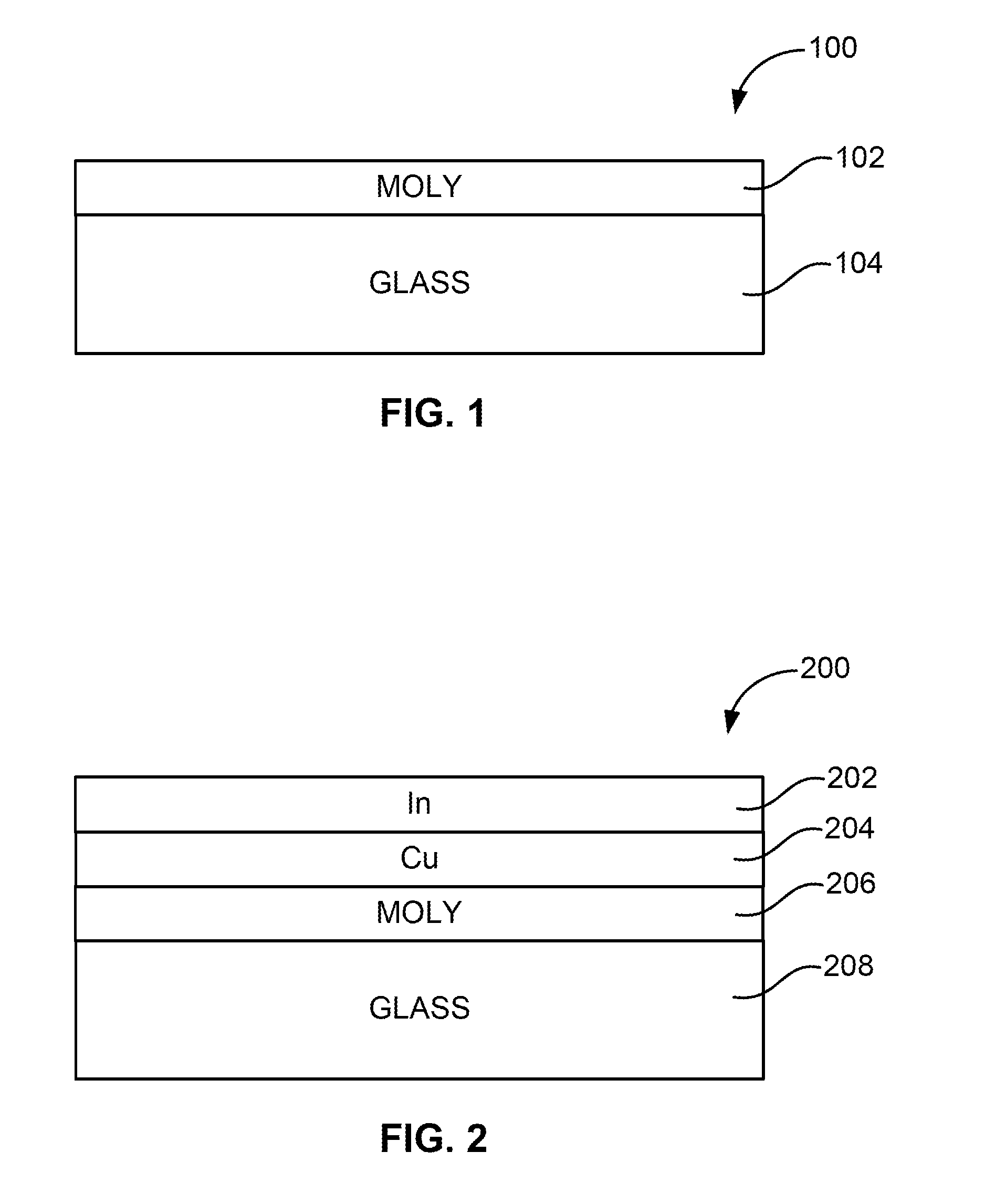

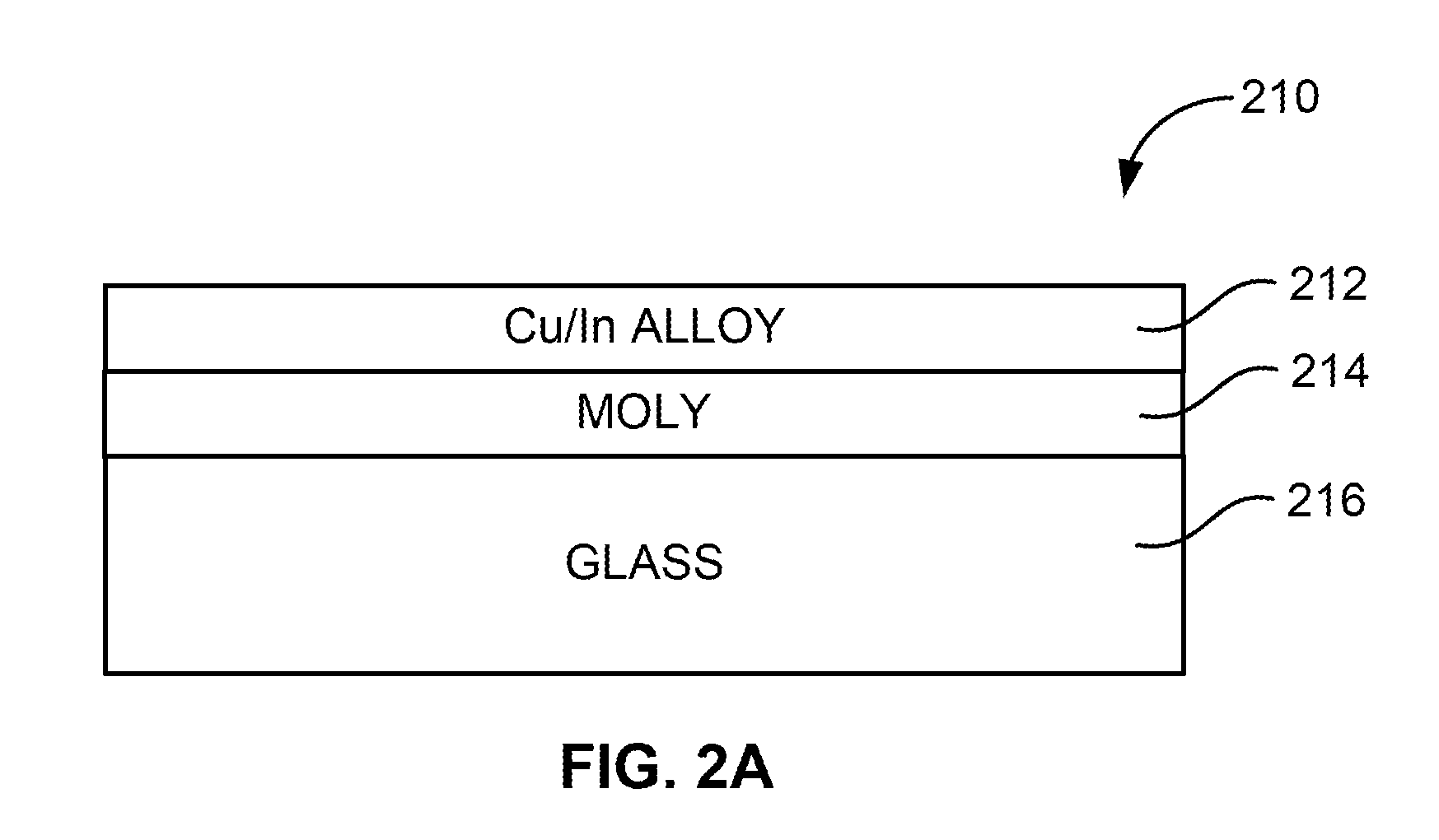

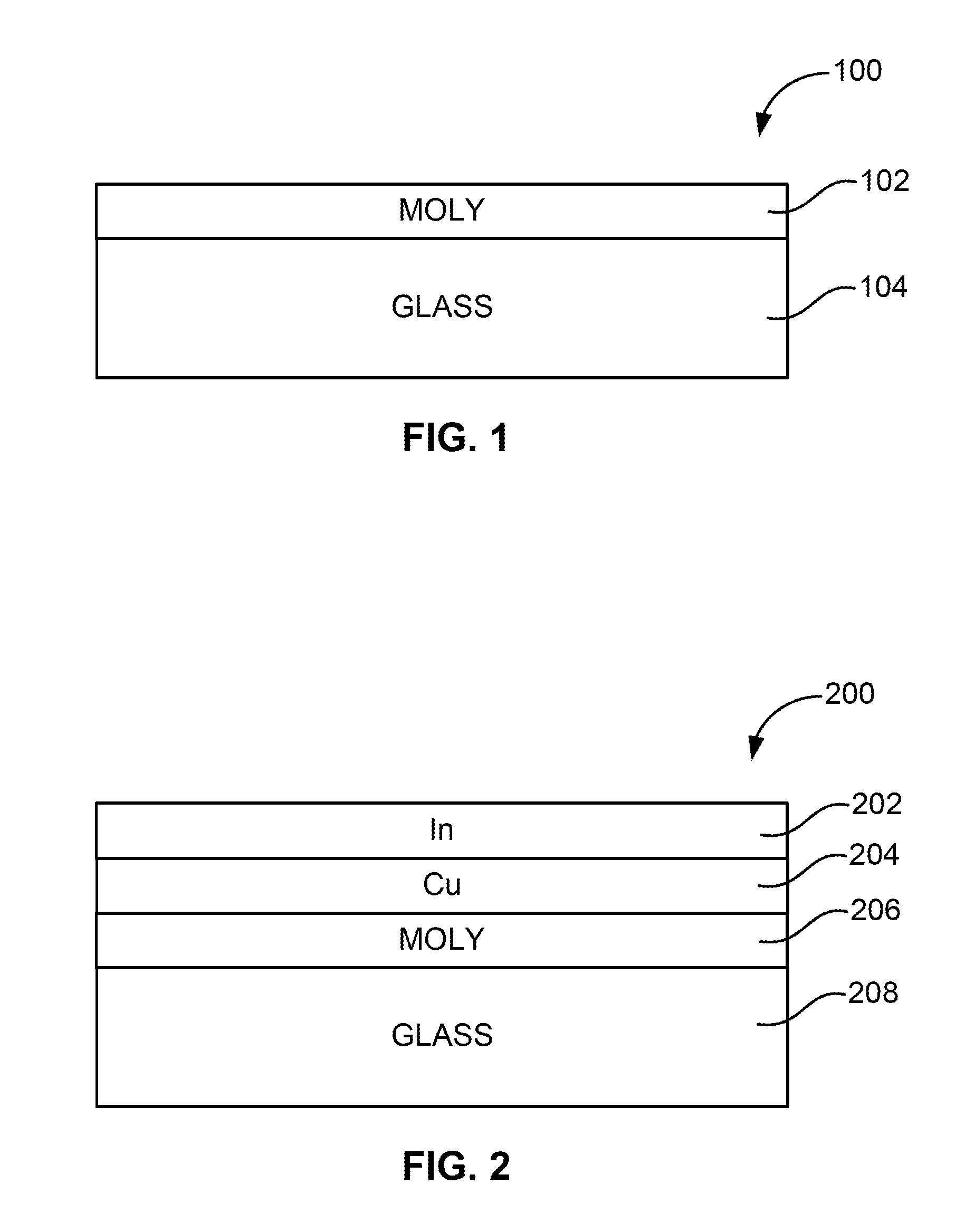

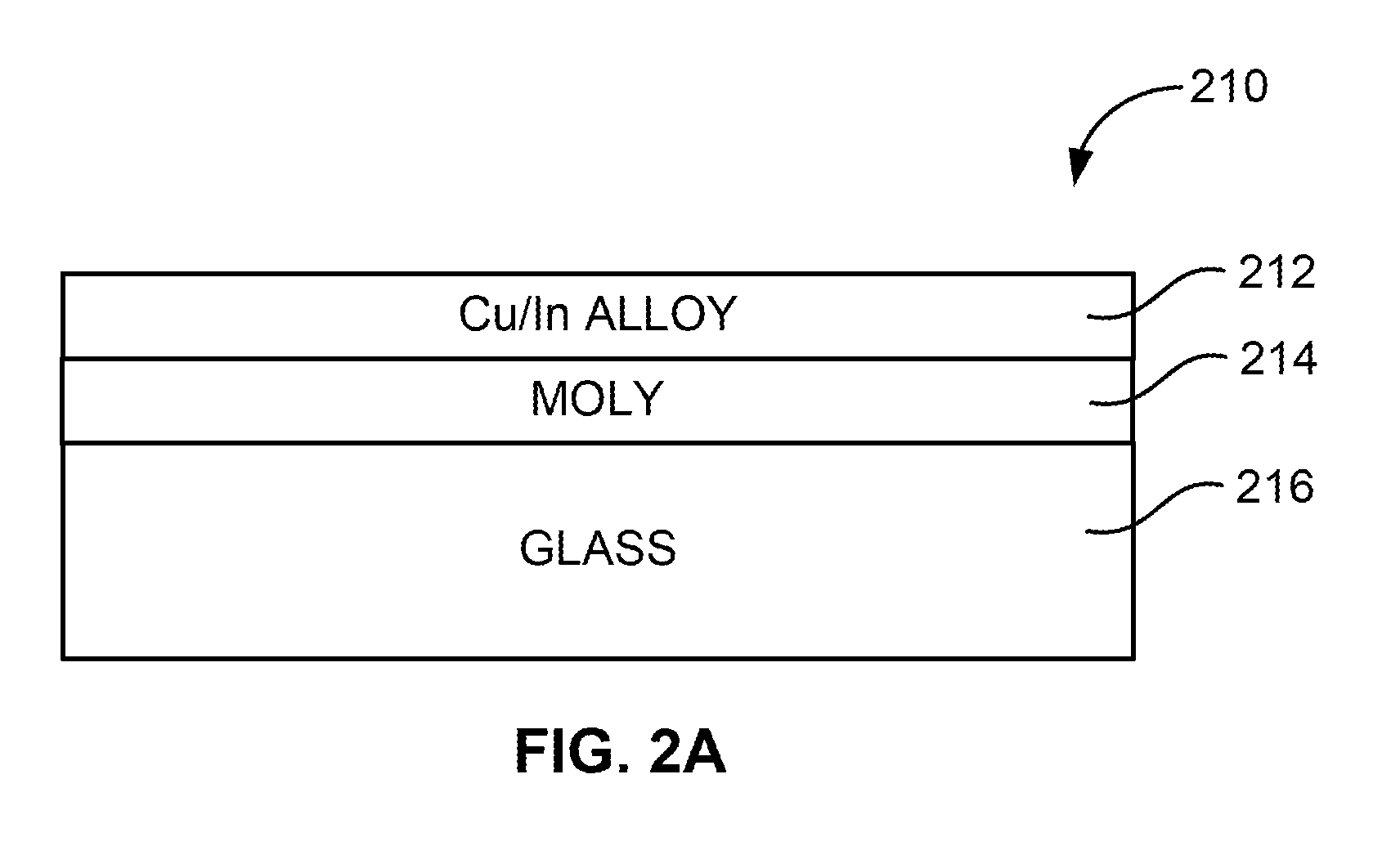

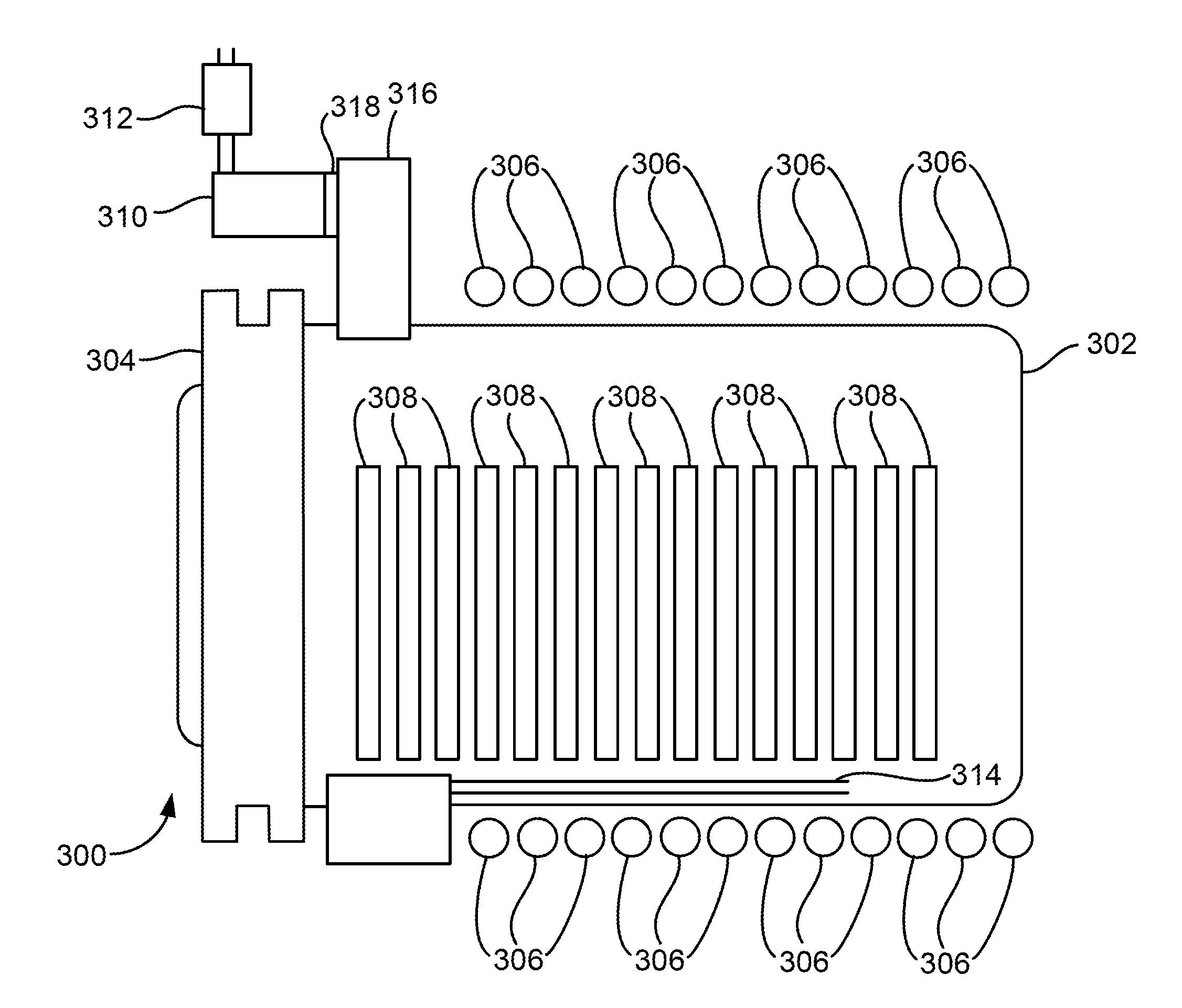

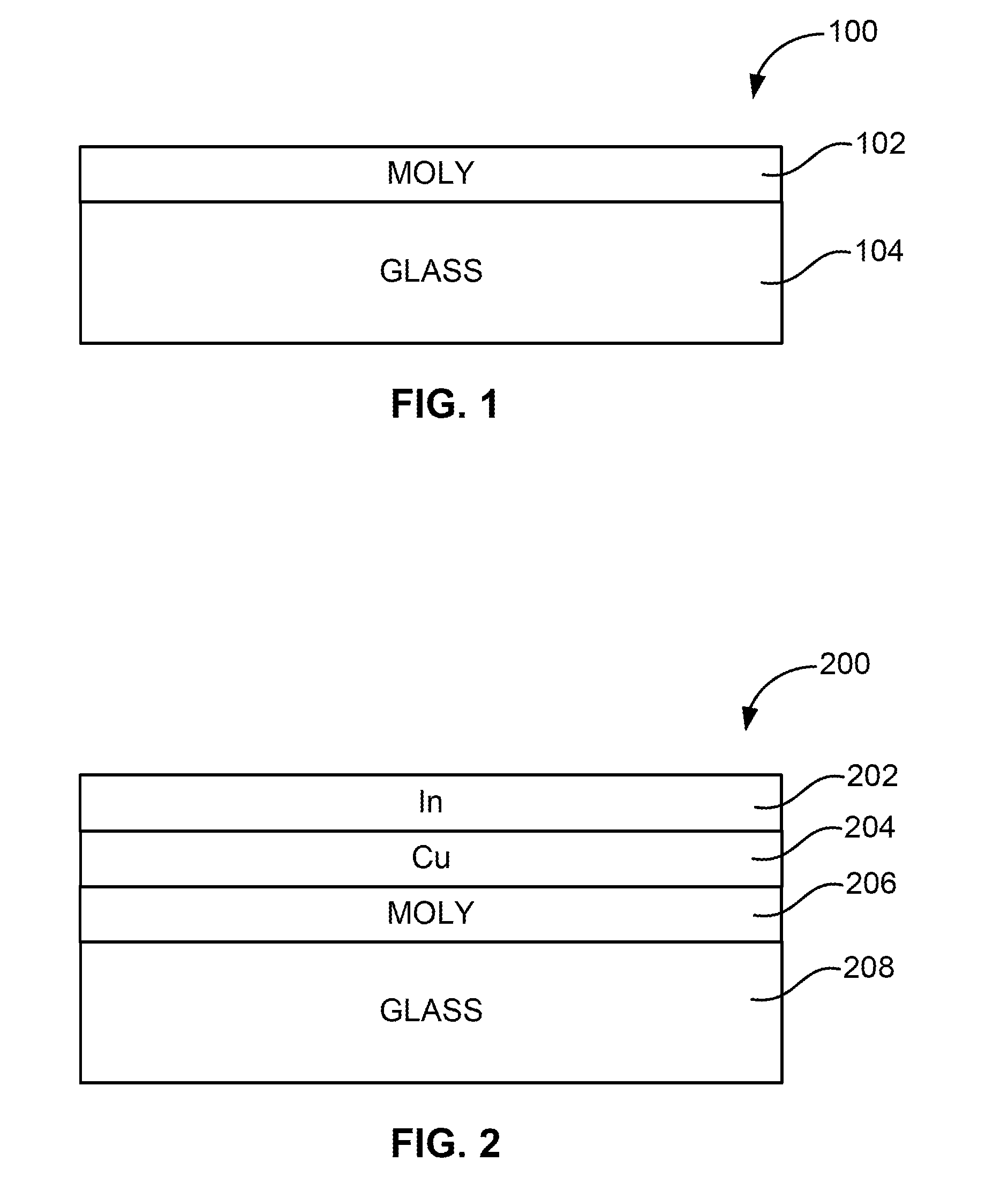

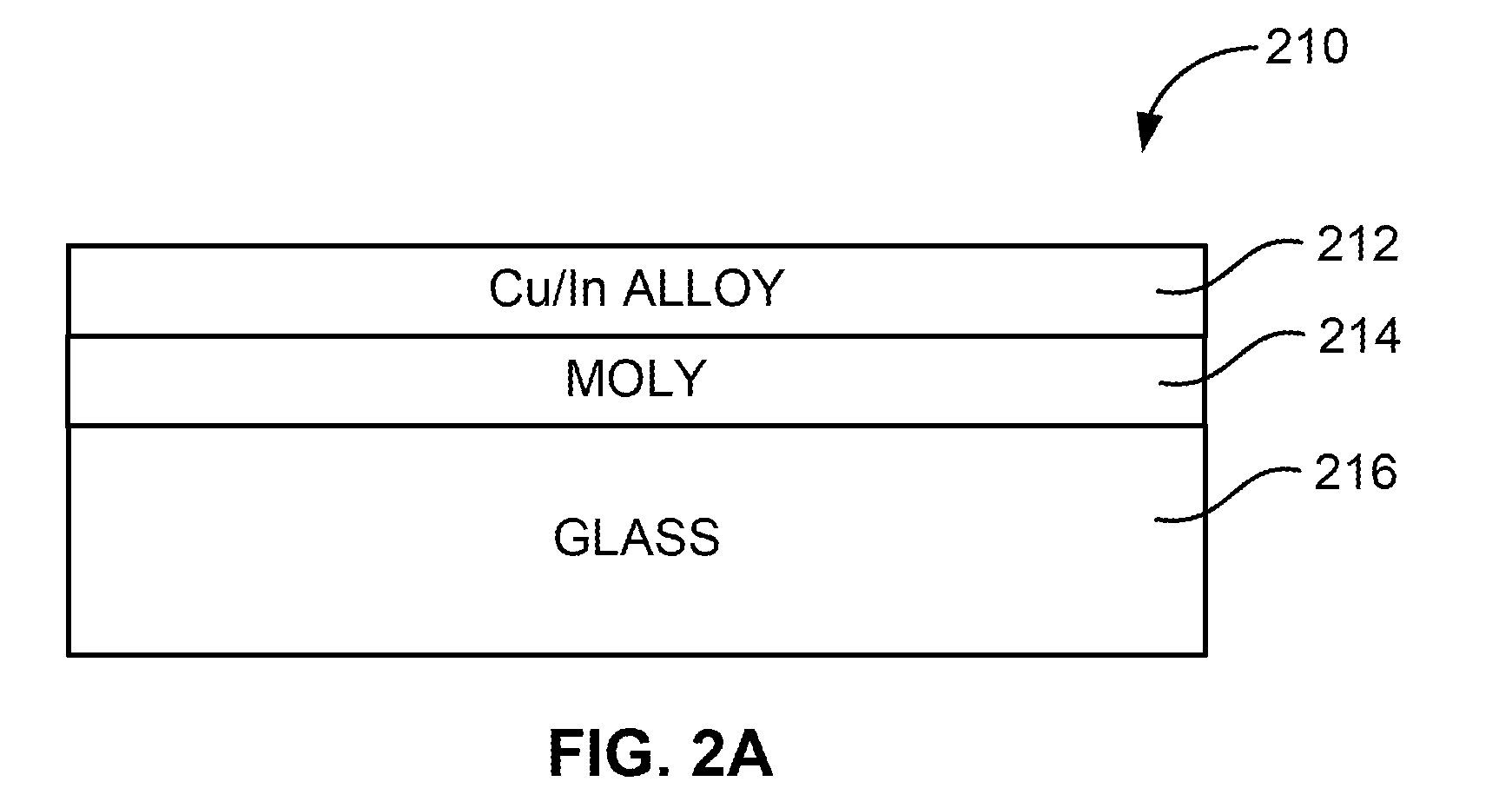

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

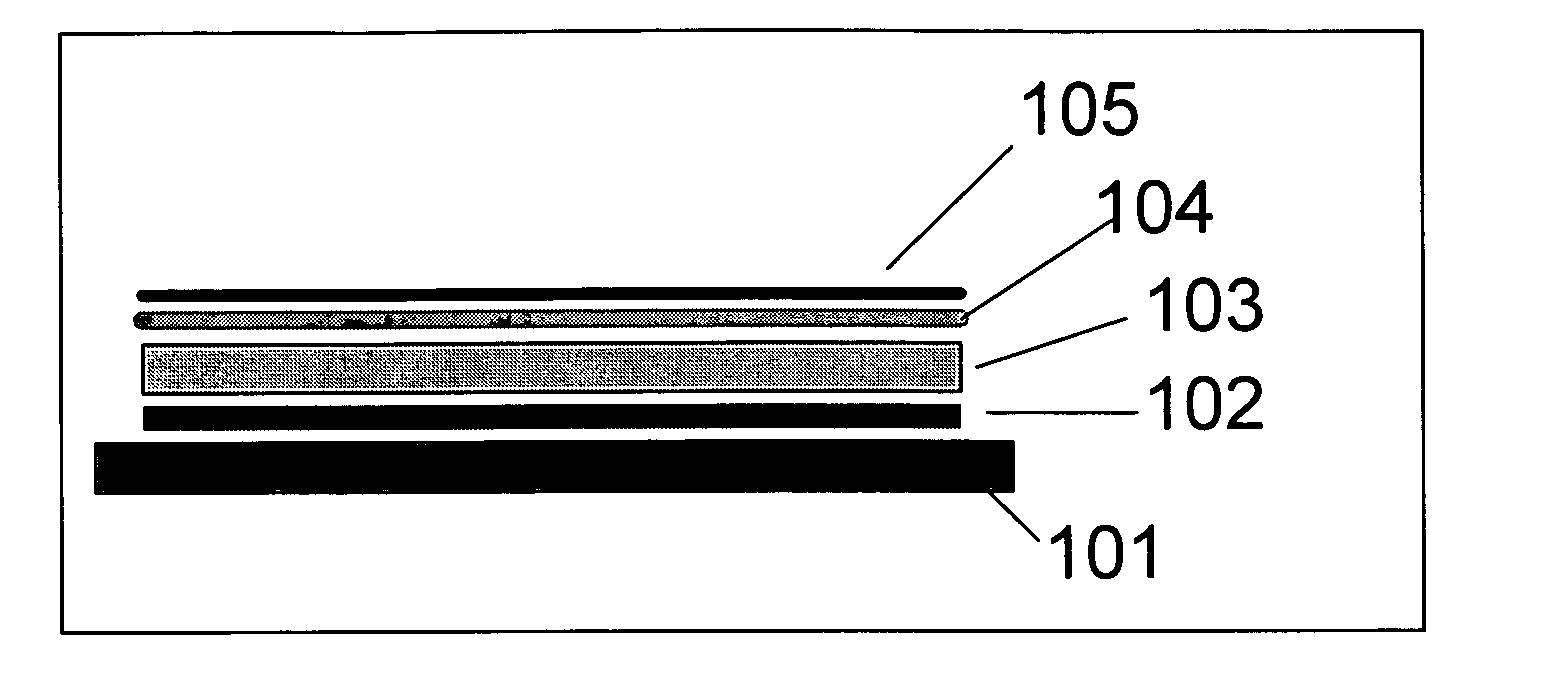

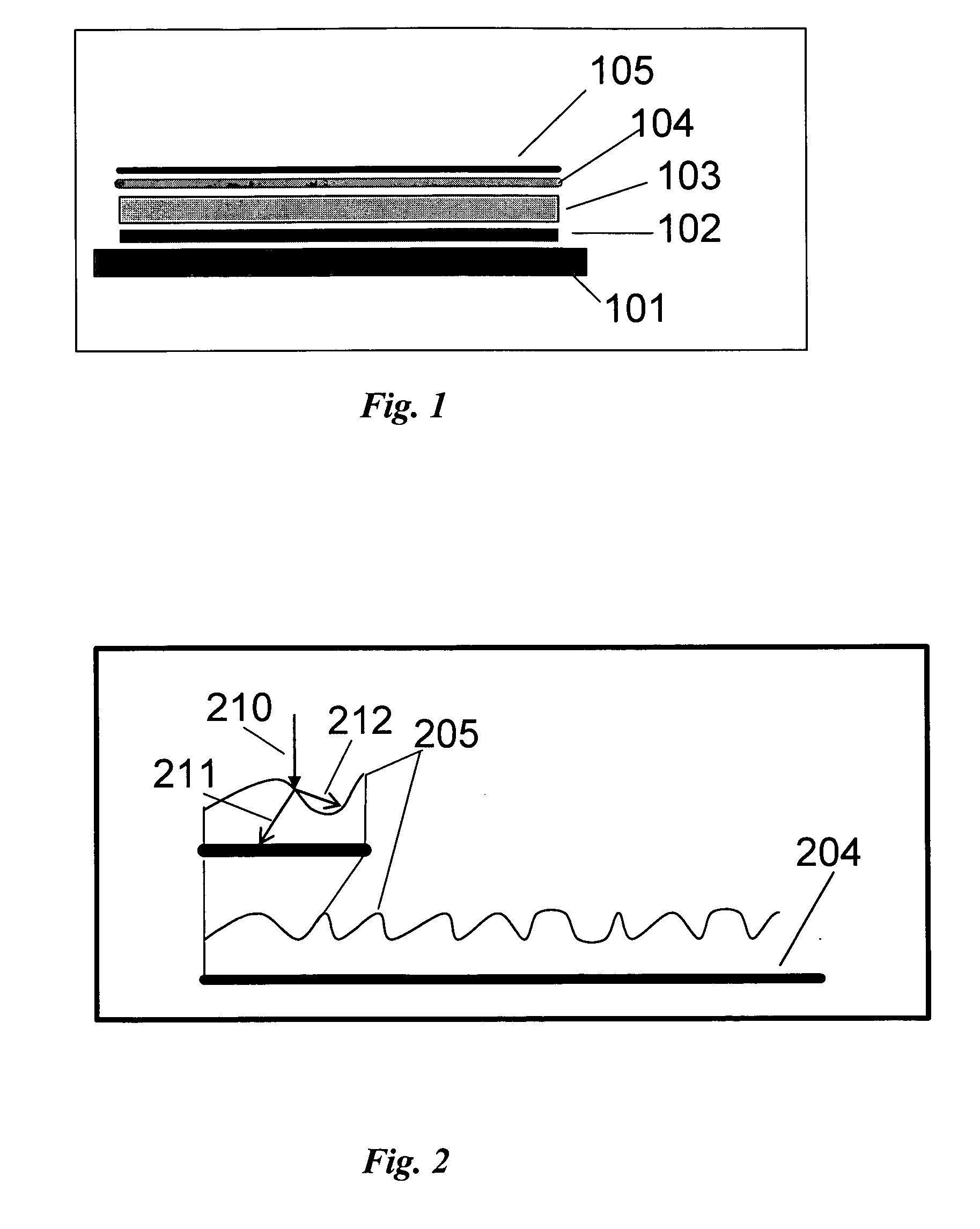

Method and Structure for Integrated Solar Cell LCD Panel

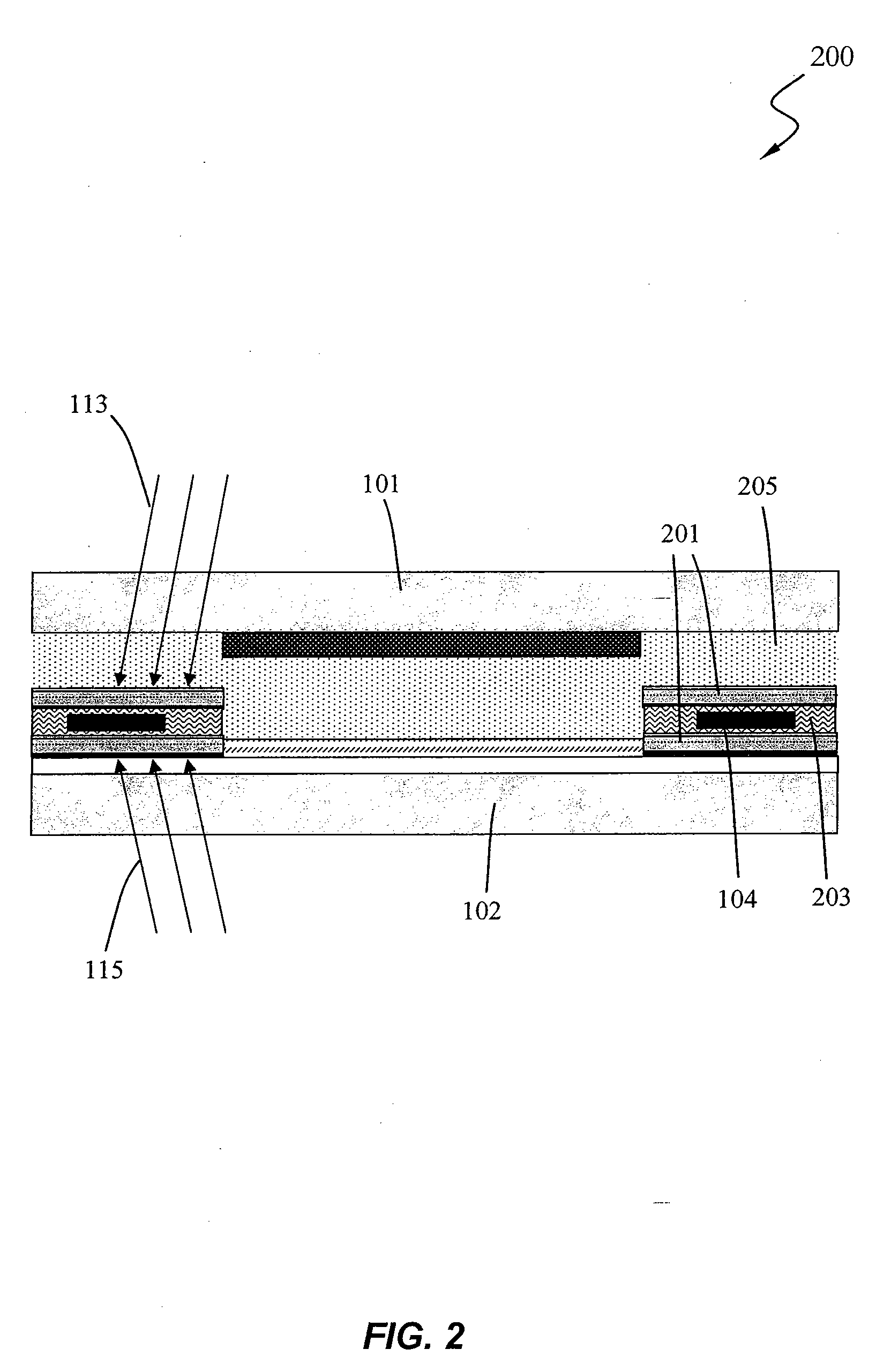

InactiveUS20070102035A1Improve fill rateIncrease cell areaPV power plantsPhotovoltaic energy generationEngineeringSolar cell

The present invention relates to a method and device for integrating solar cell on LCD panels for photovoltaic electricity generation for portable electronic devices. According to one embodiment of the present invention, the black matrix region on the color filter substrate in a LCD panel is replaced by a solar cell region. A lens array substrate is coupled between the light source layer and the TFT to focus the backlight to increase the solar cell layer area while maintaining high fill ratio of the LCD pixels. The solar cell material is selected from at least silicon, a single crystal silicon, poly-crystalline silicon, amorphous silicon, gallium arsenide, cadmium telluride, copper indium diselenide, organic / inorganic, or hybrid cells. The substrate material is selected from glass, metal, plastic or polymer.

Owner:XIAI CHARLES YANG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070690A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070683A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070684A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070685A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070682A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070688A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070687A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070689A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070686A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of CIS and /or CIGS based thin films overlying glass substrates

InactiveUS7955891B2Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Visible/near infrared image sensor array

InactiveUS7436038B2Television system detailsTelevision system scanning detailsSensor arrayLow earth orbit

A MOS or CMOS sensor for high performance imaging in broad spectral ranges including portions of the infrared spectral band. These broad spectral ranges may also include portions or all of the visible spectrum, therefore the sensor has both daylight and night vision capabilities. The sensor includes a continuous multi-layer photodiode structure on a many pixel MOS or CMOS readout array where the photodiode structure is chosen to include responses in the near infrared spectral ranges. A preferred embodiment incorporates a microcrystalline copper indium diselenide / cadmium sulfide photodiode structure on a CMOS readout array. An alternate preferred embodiment incorporates a microcrystalline silicon germanium photodiode structure on a CMOS readout array. Each of these embodiments provides night vision with image performance that greatly surpasses the GEN III night vision technology in terms of enhanced sensitivity, pixel size and pixel count. Further advantages of the invention include low electrical bias voltages, low power consumption, compact packaging, and radiation hardness. In special preferred embodiments CMOS stitching technology is used to provide multi-million pixel focal plane array sensors. One embodiments of the invention made without stitching is a two-million pixel sensor. Other preferred embodiments available using stitching techniques include sensors with 250 million (or more) pixels fabricated on a single wafer. A particular application of these very high pixel count sensors is as a focal plane array for a rapid beam steering telescope in a low earth orbit satellite useful for tracking over a 1500-meter wide track with a resolution of 0.3 meter.

Owner:C PHOCUS

Recovery method of copper indium gallium selenide thin-film solar panel

ActiveCN103184338ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementRecovery methodElectrolysis

The invention provides a recovery method of a copper indium gallium selenide thin-film solar panel. The method comprises the steps that: the copper indium gallium selenide thin-film solar panel is crushed into pieces; the pieces are soaked by using a H2SO4+H2O2 system, such that a soaking liquid is obtained; the soaking liquid is filtered, such that a first leachate is obtained; with a first phase ratio of 1, the first leachate is extracted by using an extraction agent; separation is carried out, such that a first extraction liquid and a first raffinate are obtained; the extraction agent is composed of 30% of P2O4 and 70% of kerosene by volume percentage, the extraction and balance time is 5-20min; an HCl solution is adopted as a stripping agent, and the first extraction liquid is striped by using a second phase ratio, such that In and stripping residual liquid are obtained; a reducing agent is added into the first raffinate; when a reduction reaction is finished, crude Se and a second leachate are obtained by filtering; alkali is added into the second leachate, and a pH value is regulated such that the pH value is constantly higher than 14; when a reaction is finished, filtering is carried out, such that a filtering slag comprising a hydroxide of Cu and a water solution comprising Ga are obtained; the alkali is NaOH, the pH value adjustment process is to add the NaOH in the reaction process after pH=14 so that the pH is always kept more than 14 during the reaction process, and the reaction time is kept for 0.5-2h; and the water solution is electrolyzed.

Owner:FIRST SEMICON MATERIALS

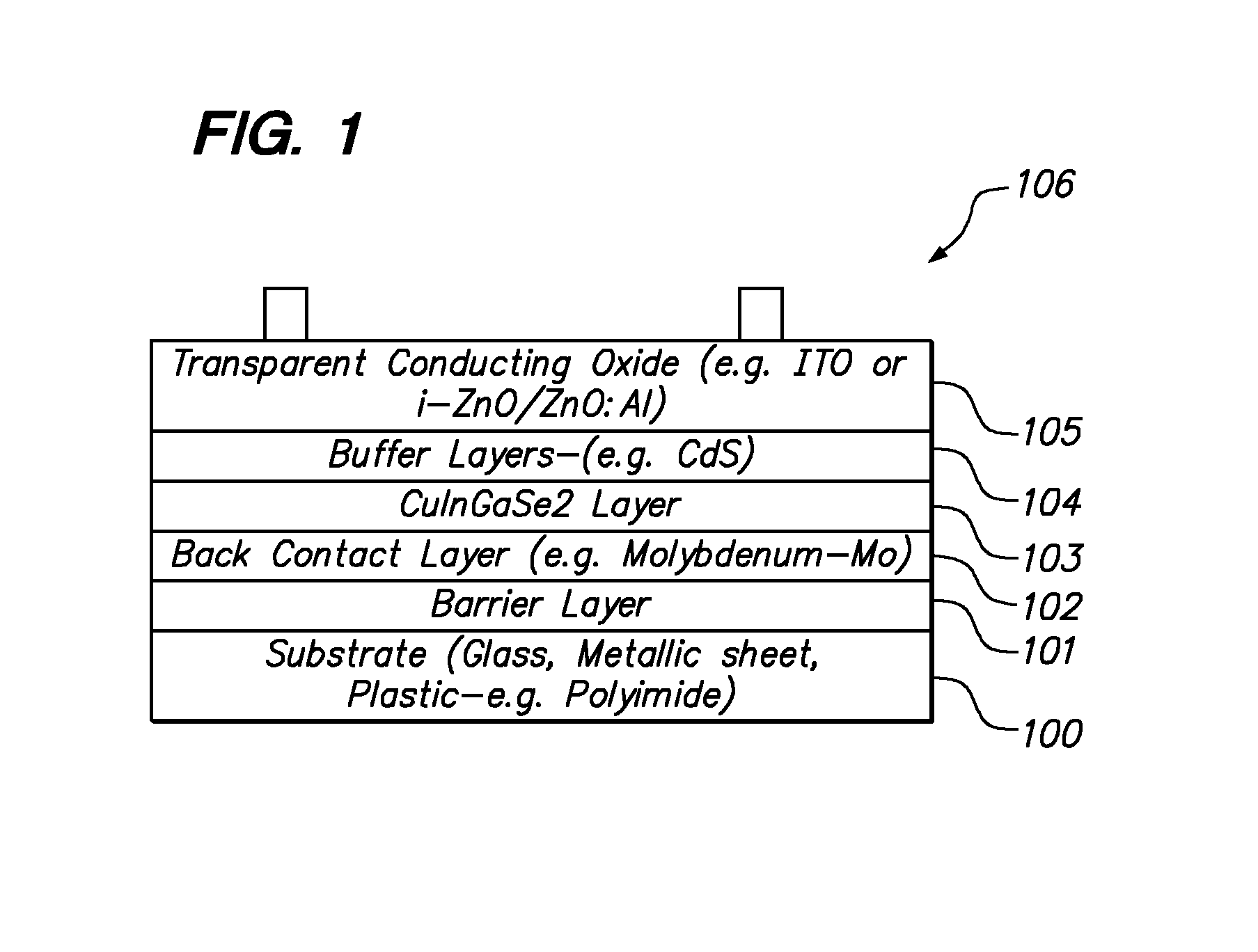

Copper Indium Diselenide-Based Photovoltaic Device And Method Of Preparing the Same

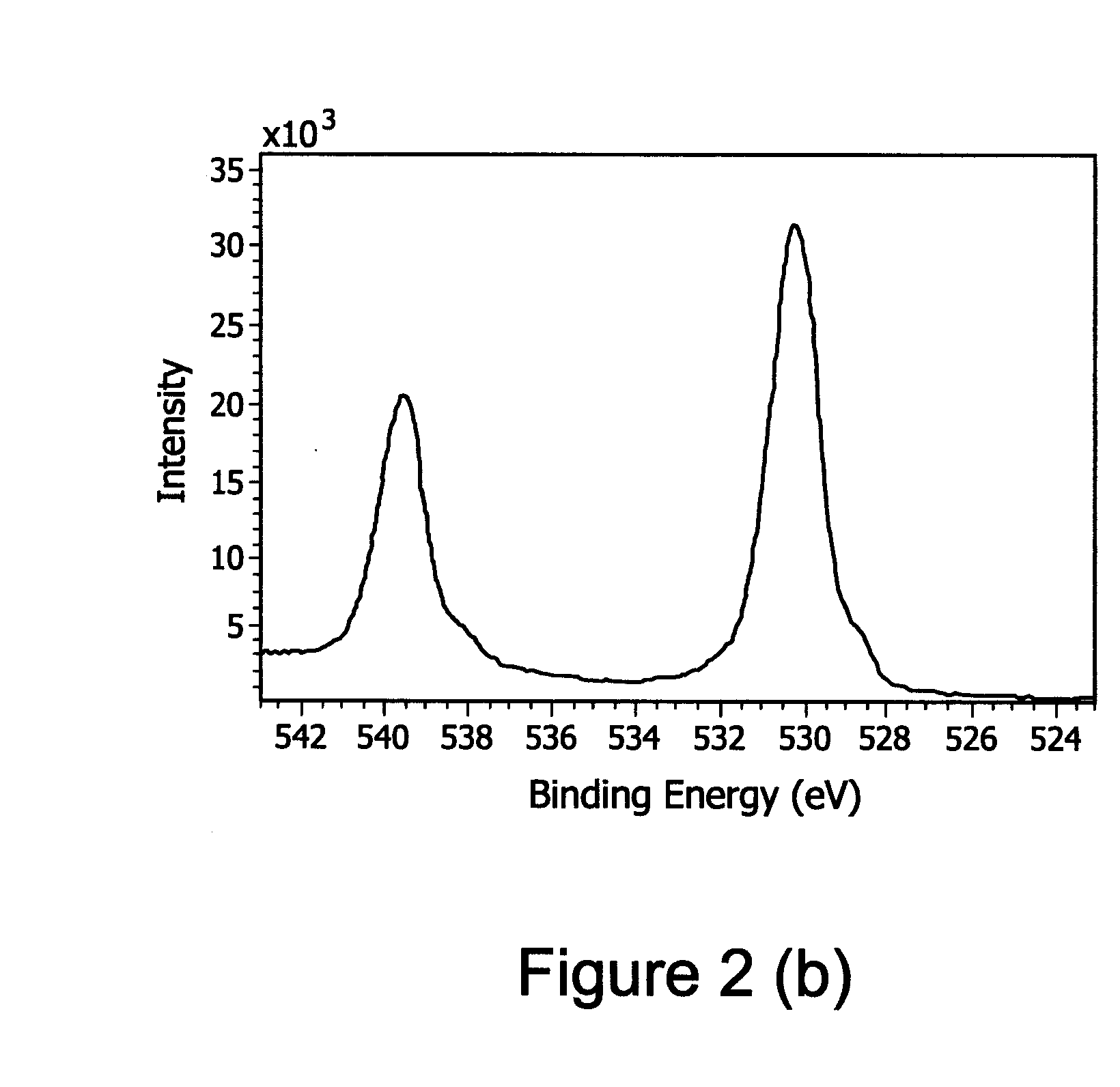

InactiveUS20090084427A1Maximum efficiencyPV power plantsFinal product manufactureIndiumPhysical chemistry

A copper indium diselenide (CIS)-based photovoltaic device includes a CIS-based solar absorber layer including copper, indium, and selenium. The CIS-based photovoltaic device further includes a substrate formed from a silicone composition. The substrate, because it is formed from the silicone composition, is both flexible and sufficiently able to withstand annealing temperatures in excess of 500° C. to obtain maximum efficiency of the device.

Owner:ITN ENERGY SYST INC +1

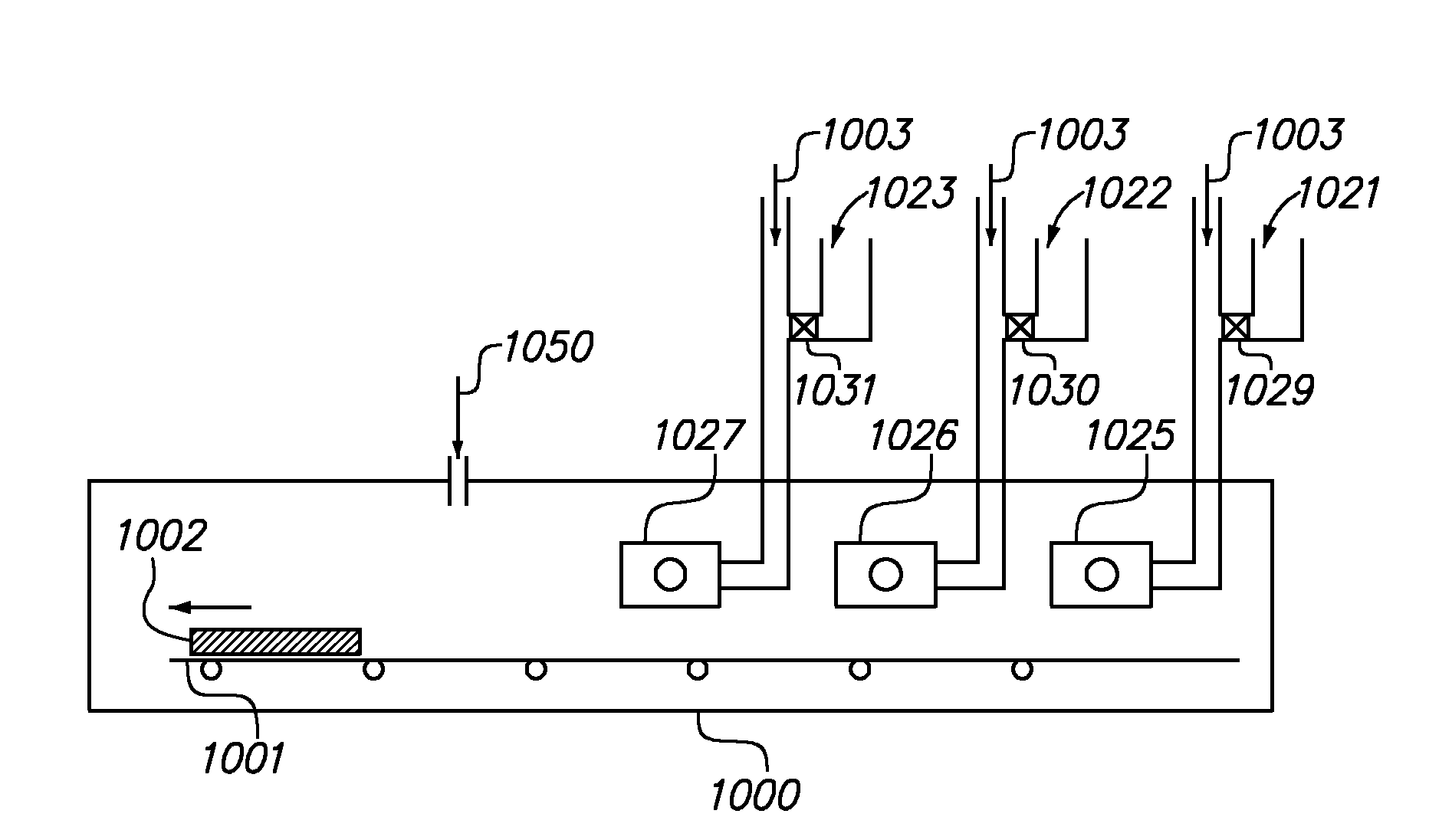

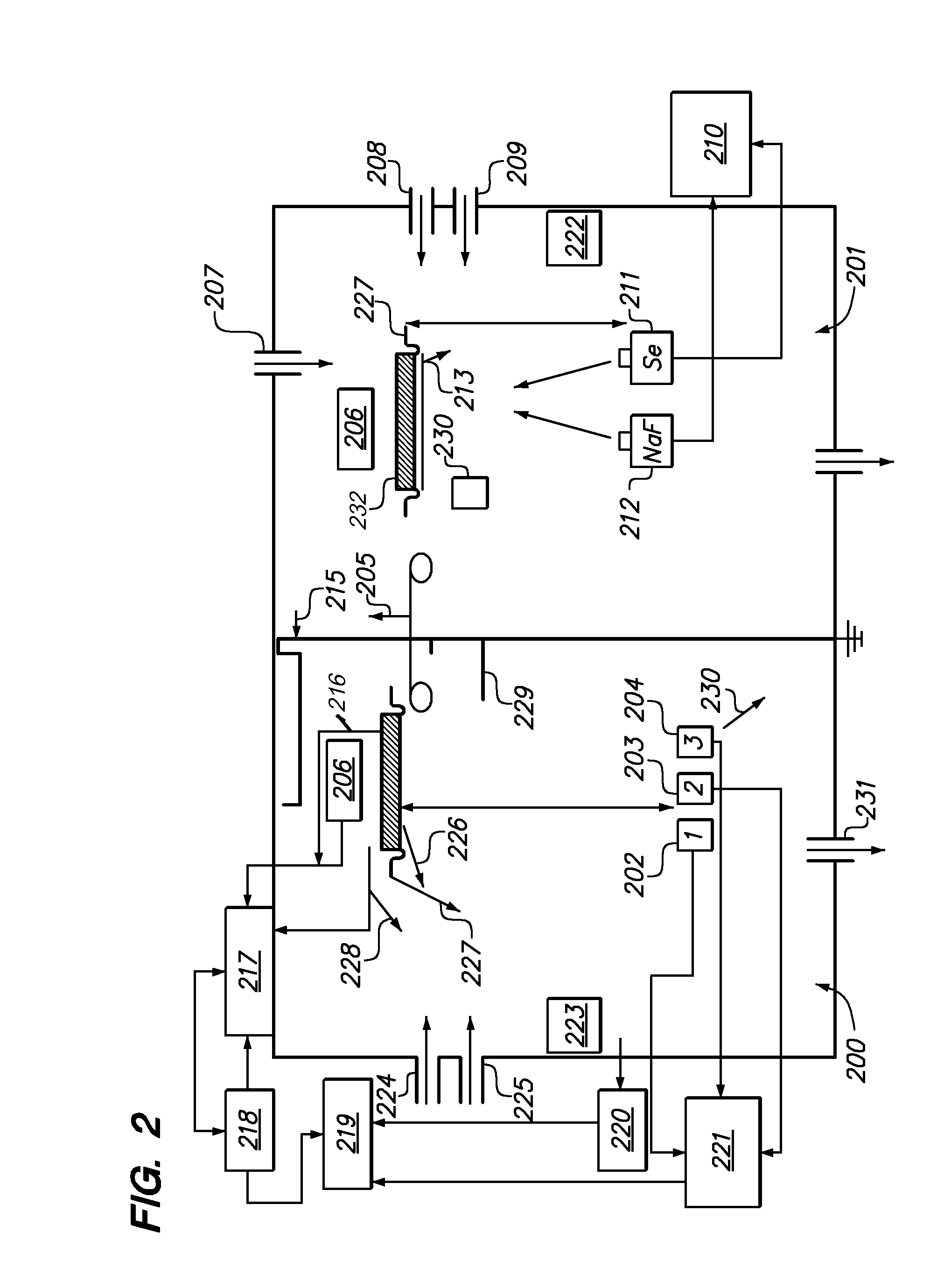

System and Method for Transferring Substrates in Large Scale Processing of CIGS and/or CIS Devices

InactiveUS20120122304A1Cost effectiveEnsure Structural IntegrityFinal product manufactureVacuum evaporation coatingThermal energyIndium

The present invention provides methods for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates having a copper and indium composite structure, and including a peripheral region, the peripheral region including a plurality of openings, the plurality of openings including at least a first opening and a second opening. The method includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the furnace including a holding apparatus. The method further includes introducing a gaseous species into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature to at least initiate formation of a copper indium diselenide film on each of the substrates.

Owner:CM MFG

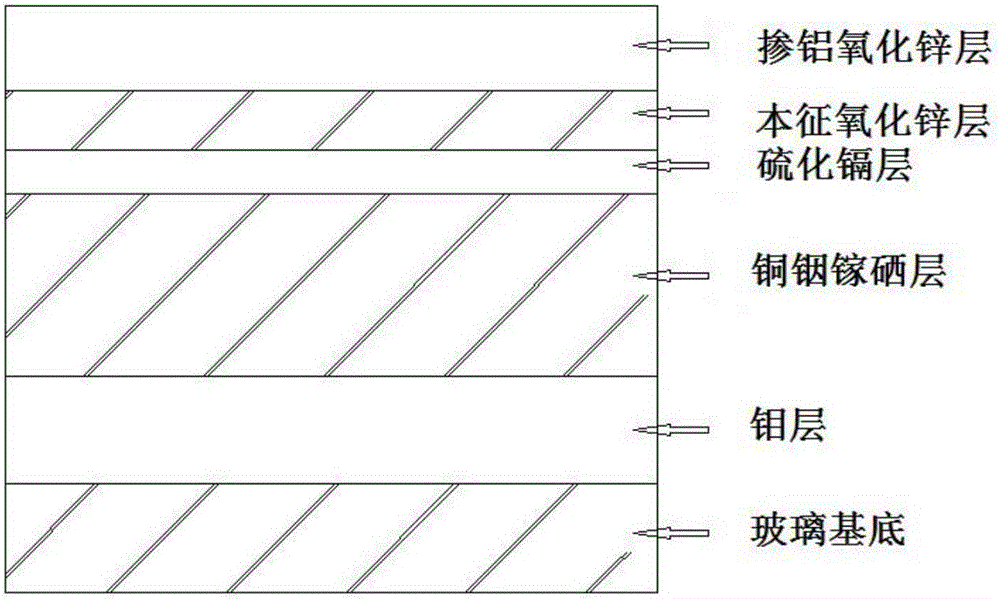

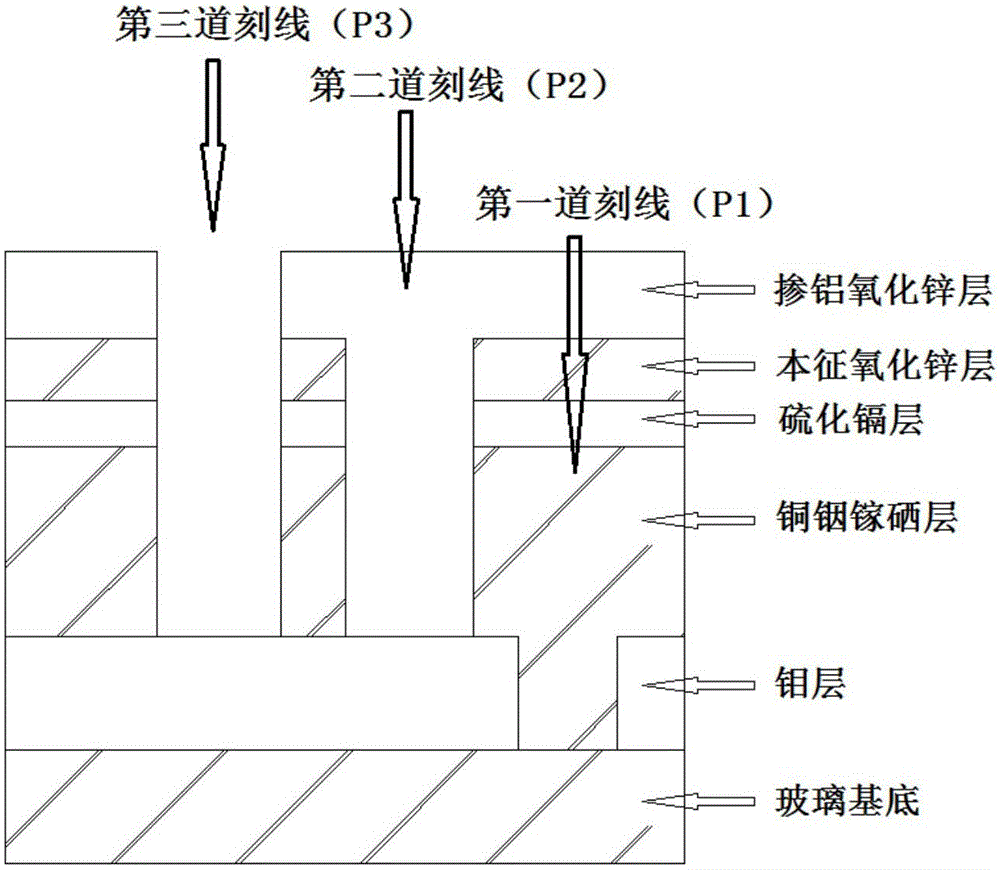

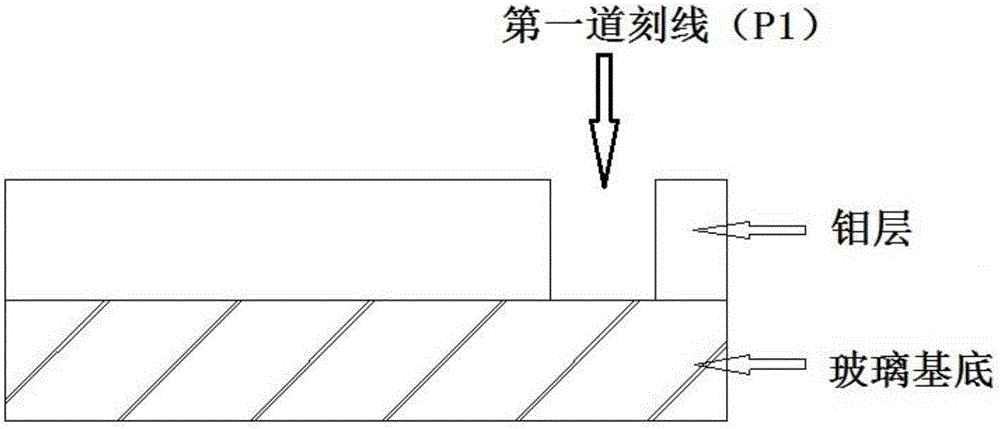

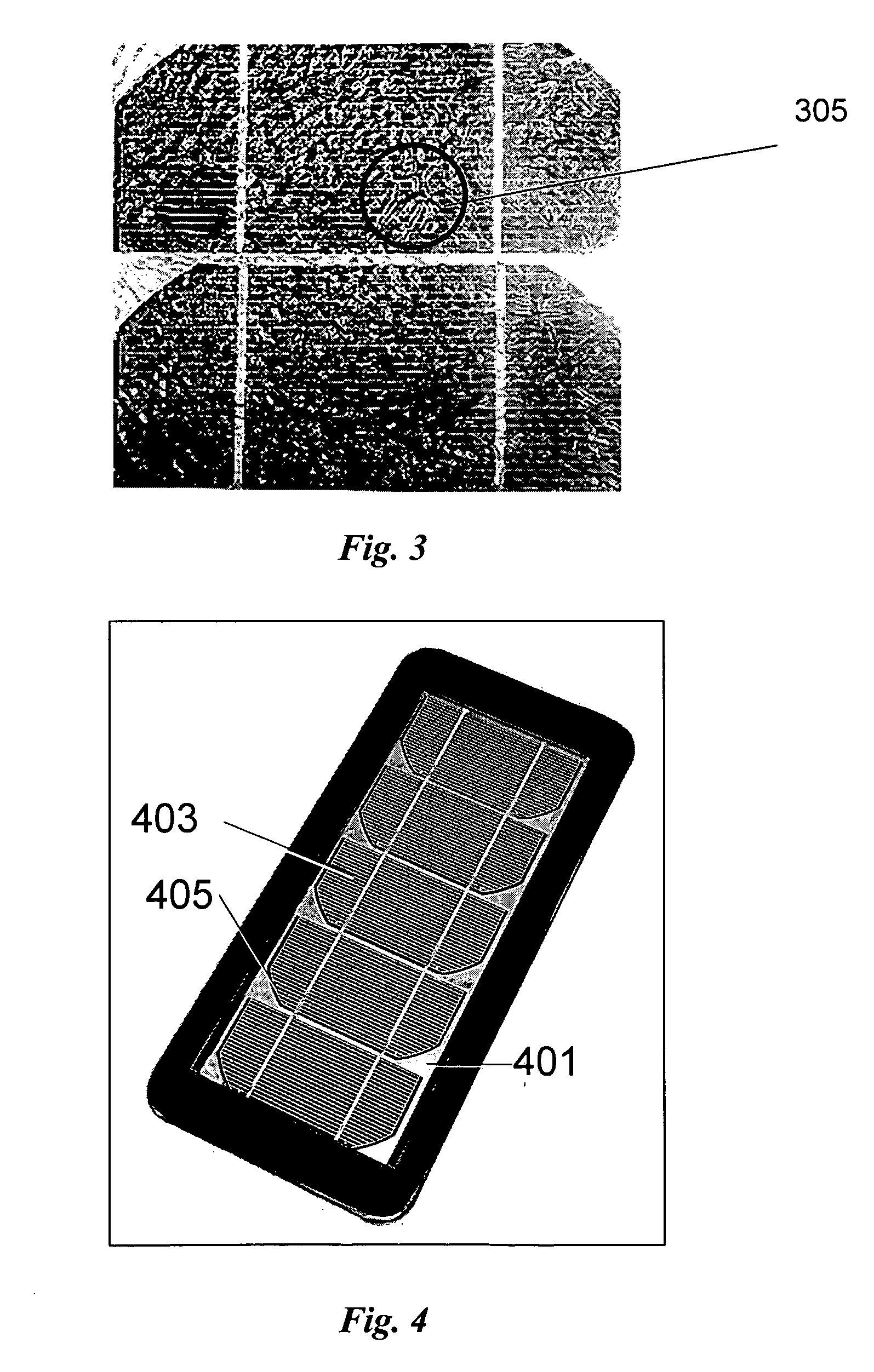

Full-laser grooving and scribing method of large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly

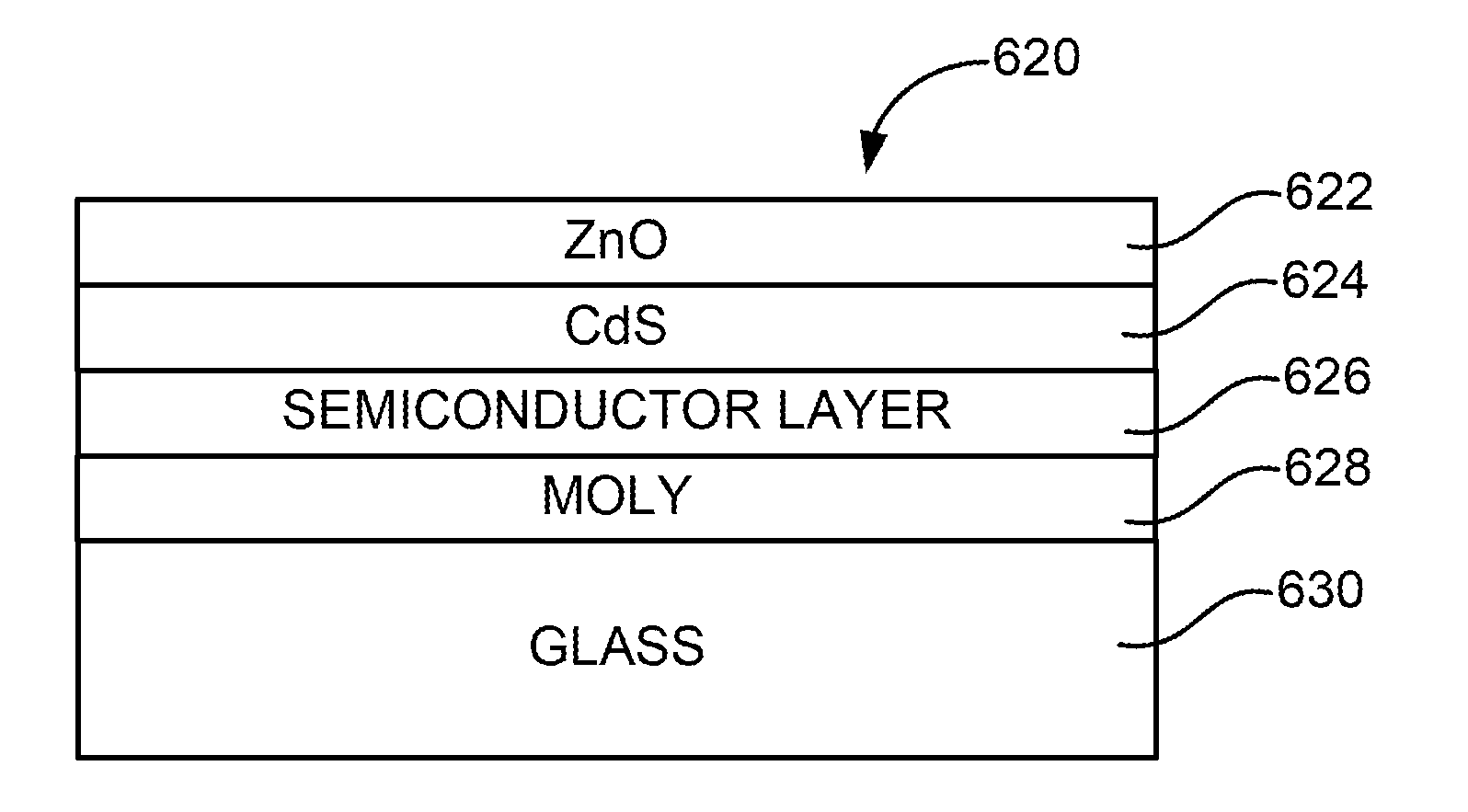

ActiveCN104993013AIncrease component powerReduce dead areaFinal product manufactureSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

The invention provides a full-laser grooving and scribing method of a large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly. The method comprises steps of using a laser to groove and scribe a molybdenum thin film prepared on soda-lime glass so as to form a first scribed line (P1); successively preparing a CIGS layer, a cadmium sulfide layer and an intrinsic zinc oxide layer on the molybdenum layer where the P1 has been grooved and scribed; after finishing the above film layer preparation, using a laser to perform grooving and scribing so as to form a second scribed line (P2) which is parallel to the P1; and after preparing an aluminum-doped zinc oxide layer on the intrinsic zinc oxide layer where the P2 has been grooved and scribed, using a laser to perform grooving and scribing so as to form a third scribed line (P3) which is parallel to the P1. According to the invention, inner join is performed for the CIGS thin-film solar cell assembly by the laser grooving and scribing method, so defects of large area of dead zones and frequency change of machinery needles in traditional machinery grooving and scribing technology can be overcome, thereby increasing efficiency of the assembly, improving stability of the grooving and scribing device and achieving objectives to reduce production cost and improve production efficiency.

Owner:BEIJING SIFANG JIBAO AUTOMATION

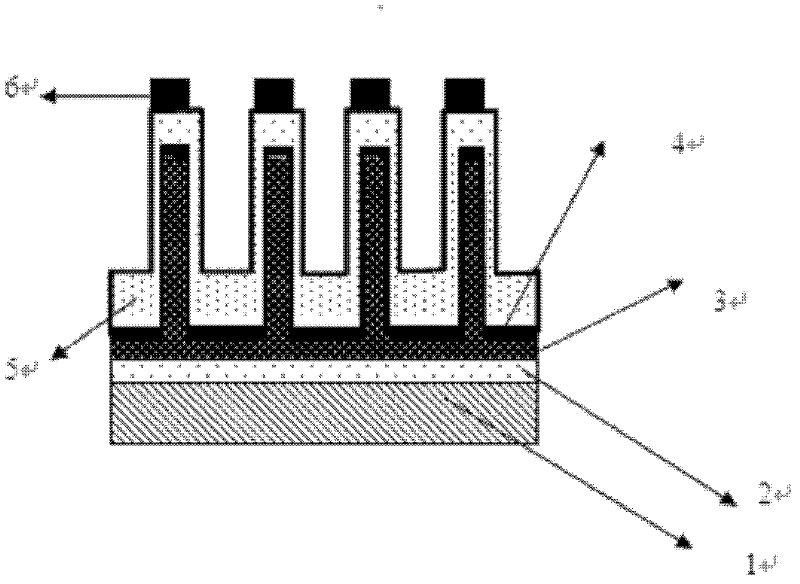

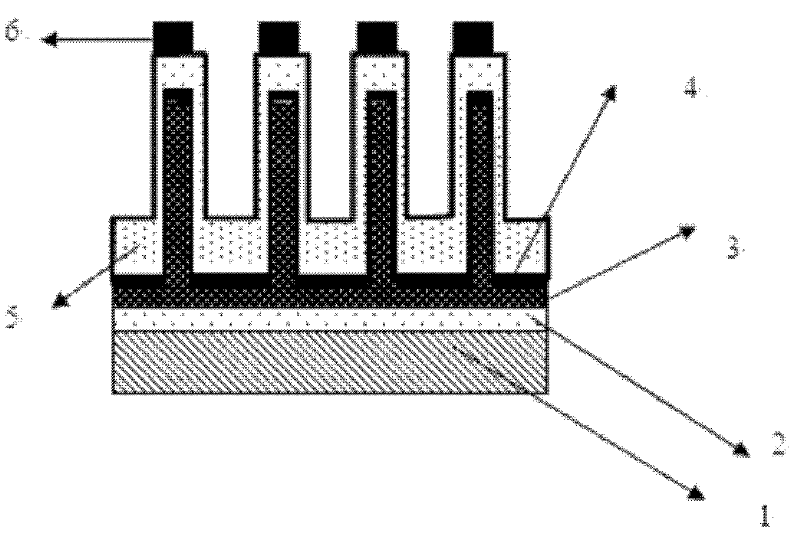

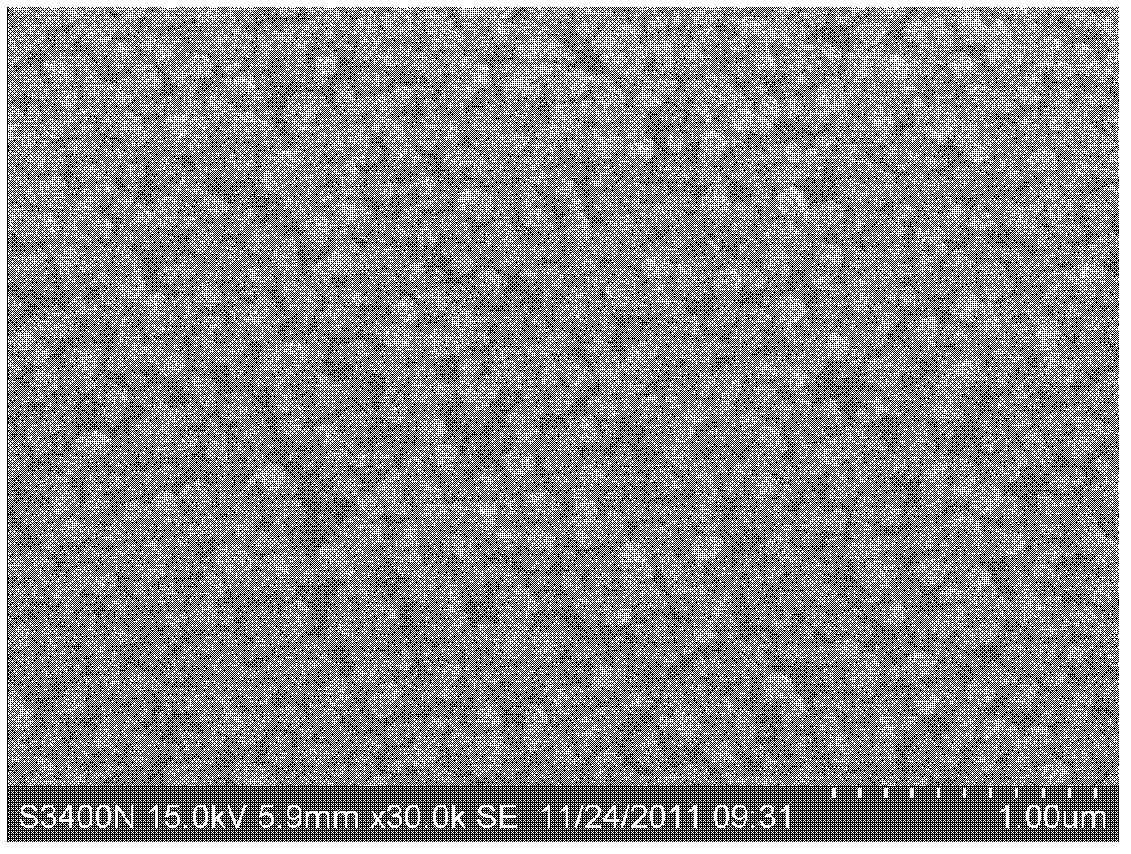

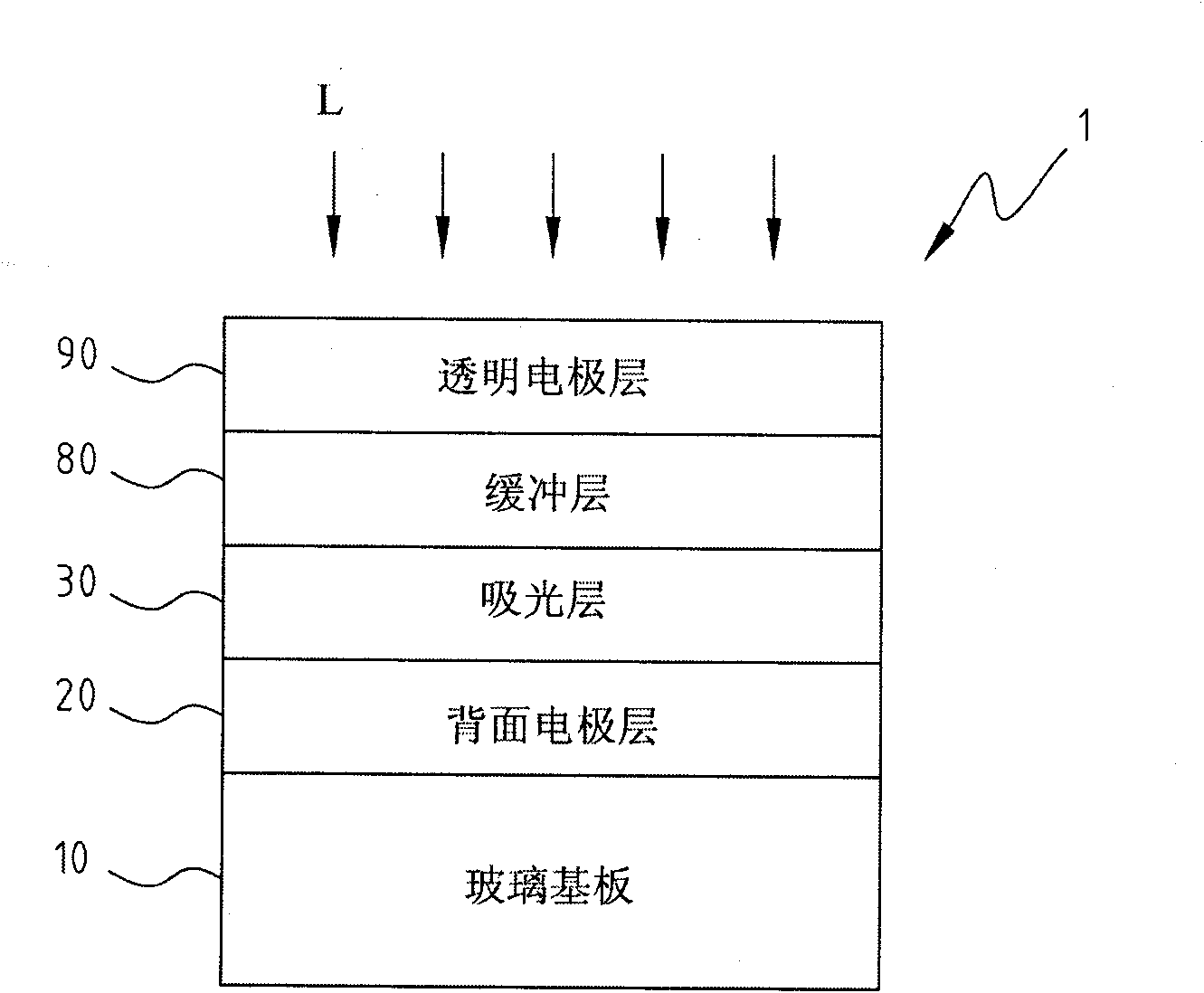

Thin-film solar photovoltaic cell with nano wire array structure and preparation method for thin-film solar photovoltaic cell

InactiveCN102569508ALow costImprove photoelectric conversion efficiencyFinal product manufactureVacuum evaporation coatingGas phaseCuprous sulfide

The invention discloses a method for preparing a thin-film solar photovoltaic cell with a copper indium gallium selenide (CIGS) nano wire array structure. The method comprises the following steps of: growing a large-area cuprous sulfide or copper sulfide nano wire array by adopting a gas-solid reaction method, and converting the cuprous sulfide or copper sulfide nano wire array into a CIGS nano wire array by physical vapor deposition and heat treatment methods. The component, the phase structure and the energy band structure of the semiconductor nano wire array can be regulated by controlling the categories of deposition elements, the deposition sequence, the deposition process, post treatment and the like, so that solar photovoltaic cells with different structures and properties are prepared. Through the cell, light reflection is reduced, light absorption is increased, the probability of producing current carriers can be increased, the probability of recombination of holes and electrons is reduced, and the photoelectric conversion efficiency is greatly improved. The method is low in cost, the preparation processes are controllable, the prepared nano wire array is uniform in structure distribution, and preparation of the nano structural thin-film solar photovoltaic cell with large area and high photoelectric conversion efficiency can be realized.

Owner:SUN YAT SEN UNIV

Photovoltaic Module

InactiveUS20090000656A1Accelerated weatheringImprove environmental propertyPV power plantsPolyurea/polyurethane coatingsAmorphous siliconSingle crystal

The present invention involves the use of specially formulated polymers into which anti-static and conducting metal additives have been incorporated to create a flexible, optically transparent cover for mechanical protection of the incident light-facing surface of the photovoltaic cells. The polymer coating imparts higher conversion efficiencies to photovoltaic cells and modules and is resistant to the destructive effects of UV. In the preferred embodiment, the surface comprising a flexible optically transparent polymer cover has a relief or “crinkle coat” structure morphology comprising a random set of rounded ridge and valley features that impart higher conversion efficiencies to photovoltaic cells and modules due to a concentration affect.Application of the present invention yields mono-crystalline photovoltaic modules that have conversion efficiencies as high as 20%, or more, as compared to 13-14% for presently available commercial module designs. Components of the present invention can be used to increase conversion efficiency of mono-crystalline, multi-crystalline and nano-crystalline, as well as amorphous silicon photovoltaic cells and solar cells based on non-silicon systems such as CIGS (copper indium gallium selenide).

Owner:ENERIZE CORP

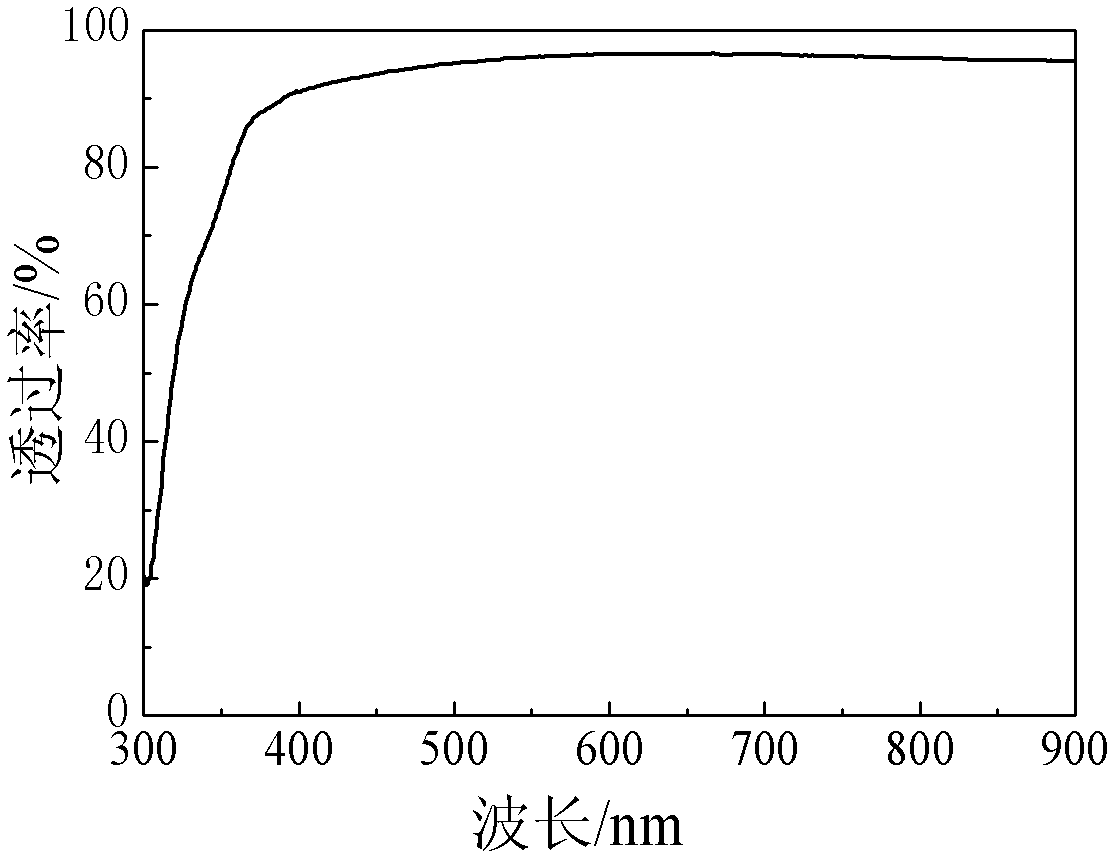

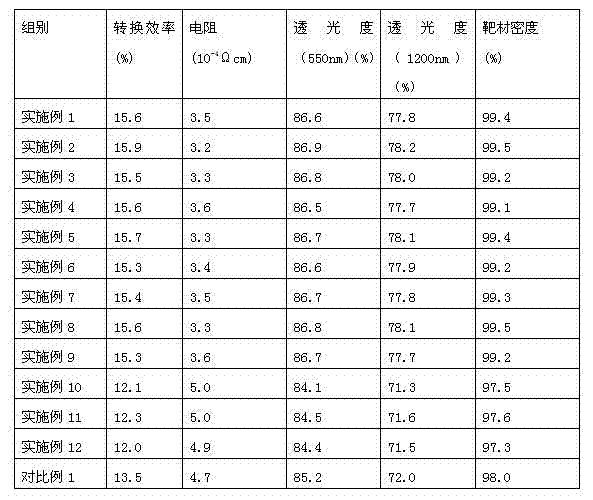

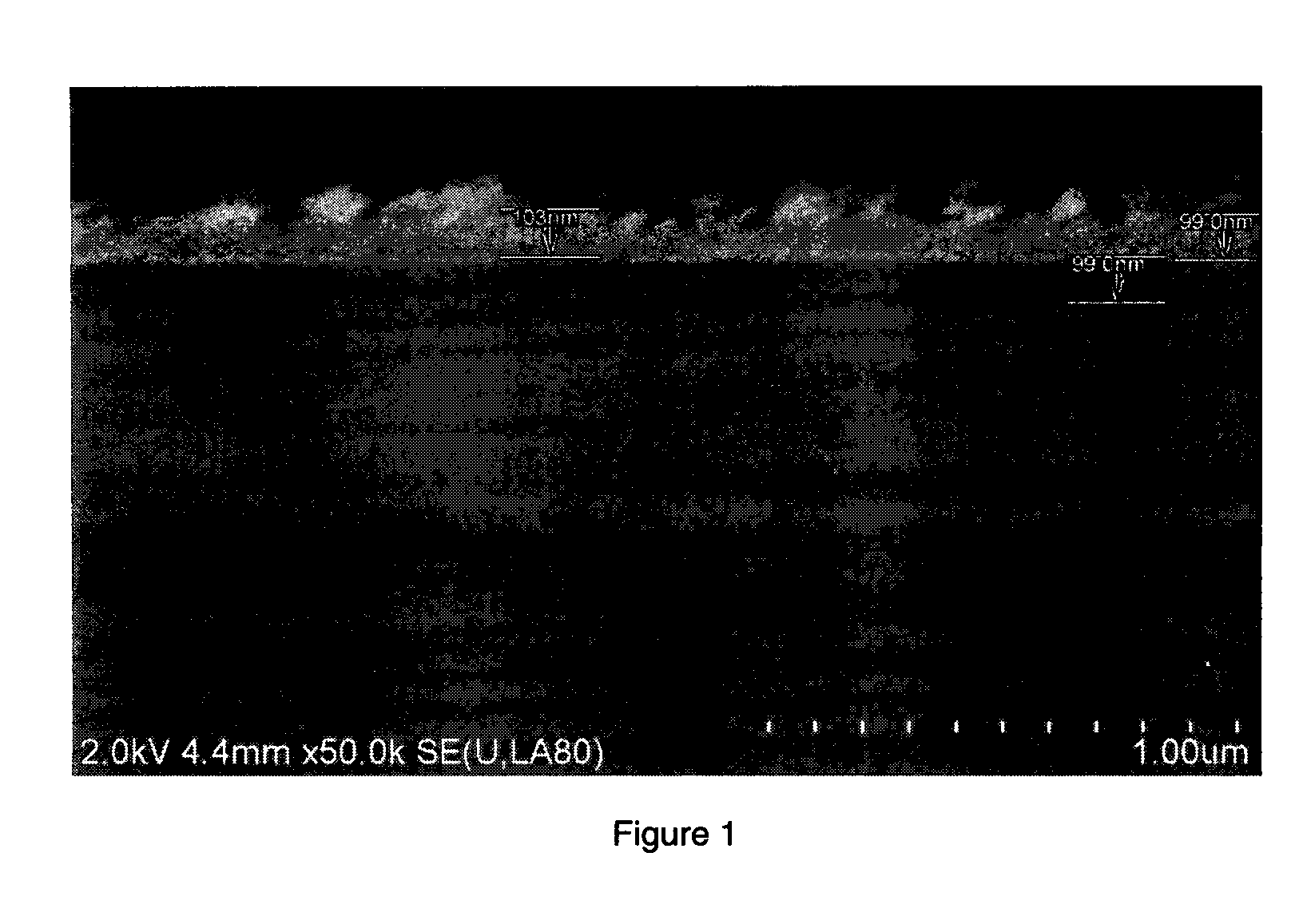

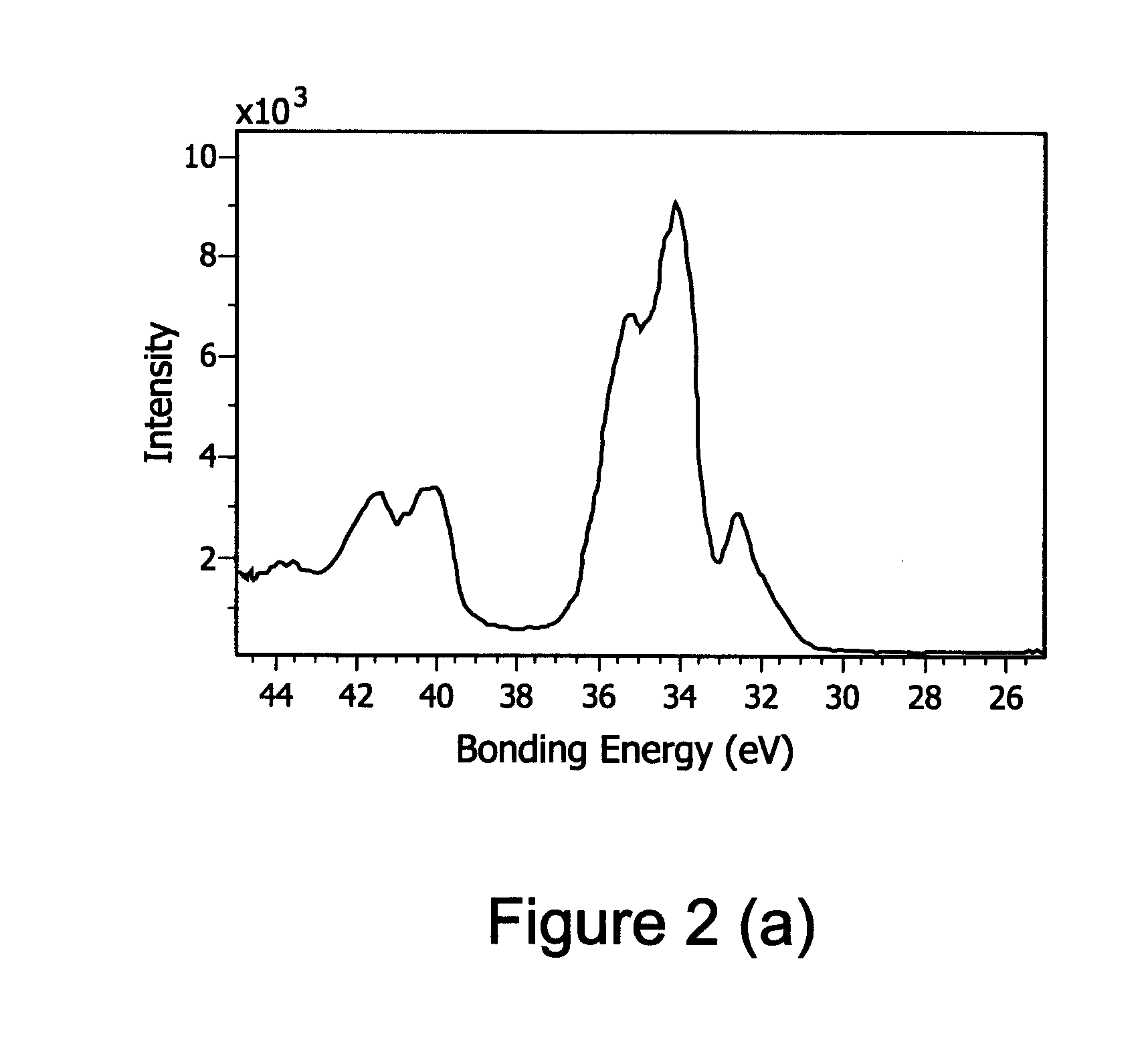

Preparation method for buffering layer material of copper indium gallium selenide film solar battery

InactiveCN102544237AQuality improvementControl reaction speedFinal product manufactureSemiconductor devicesIndiumElectrical battery

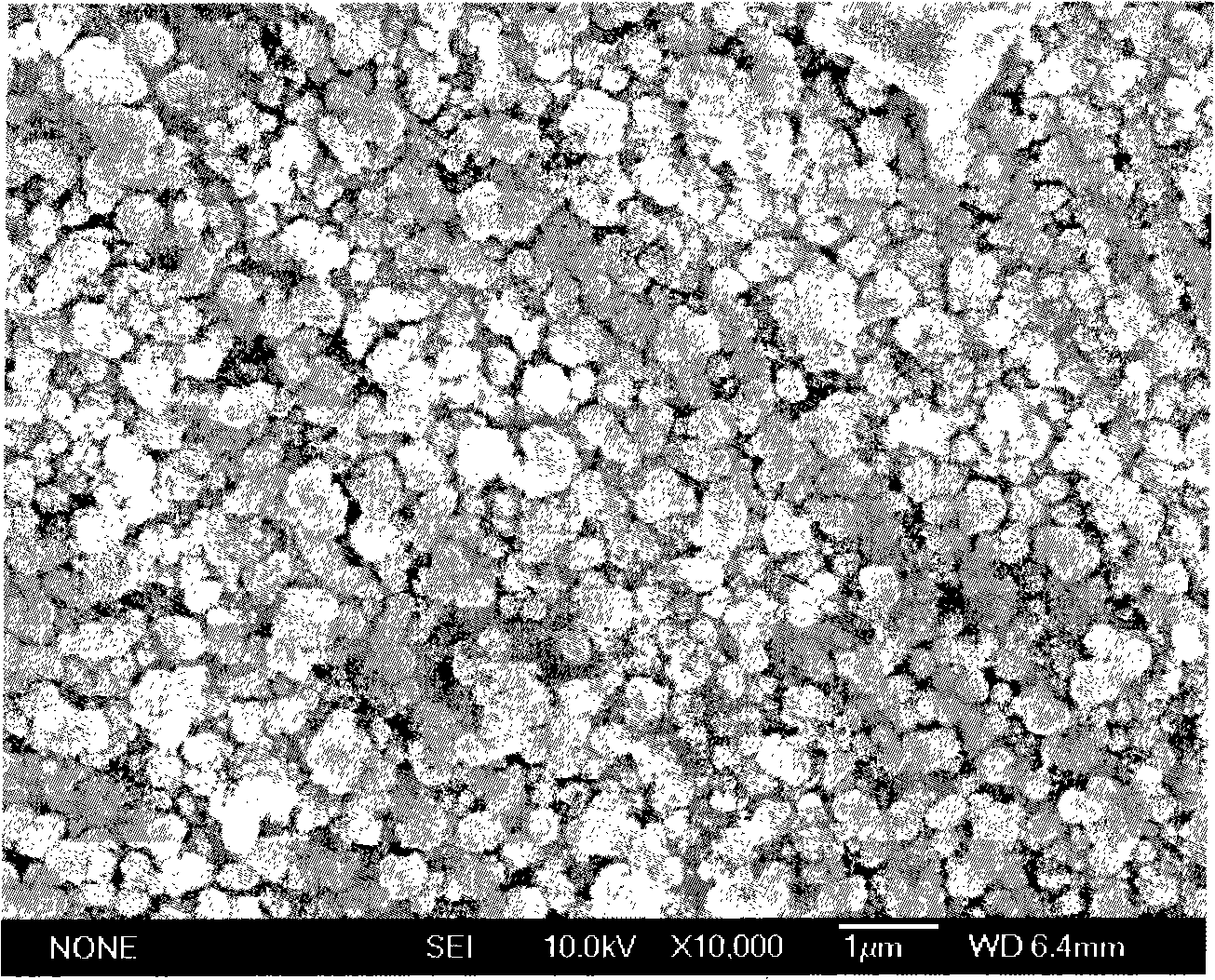

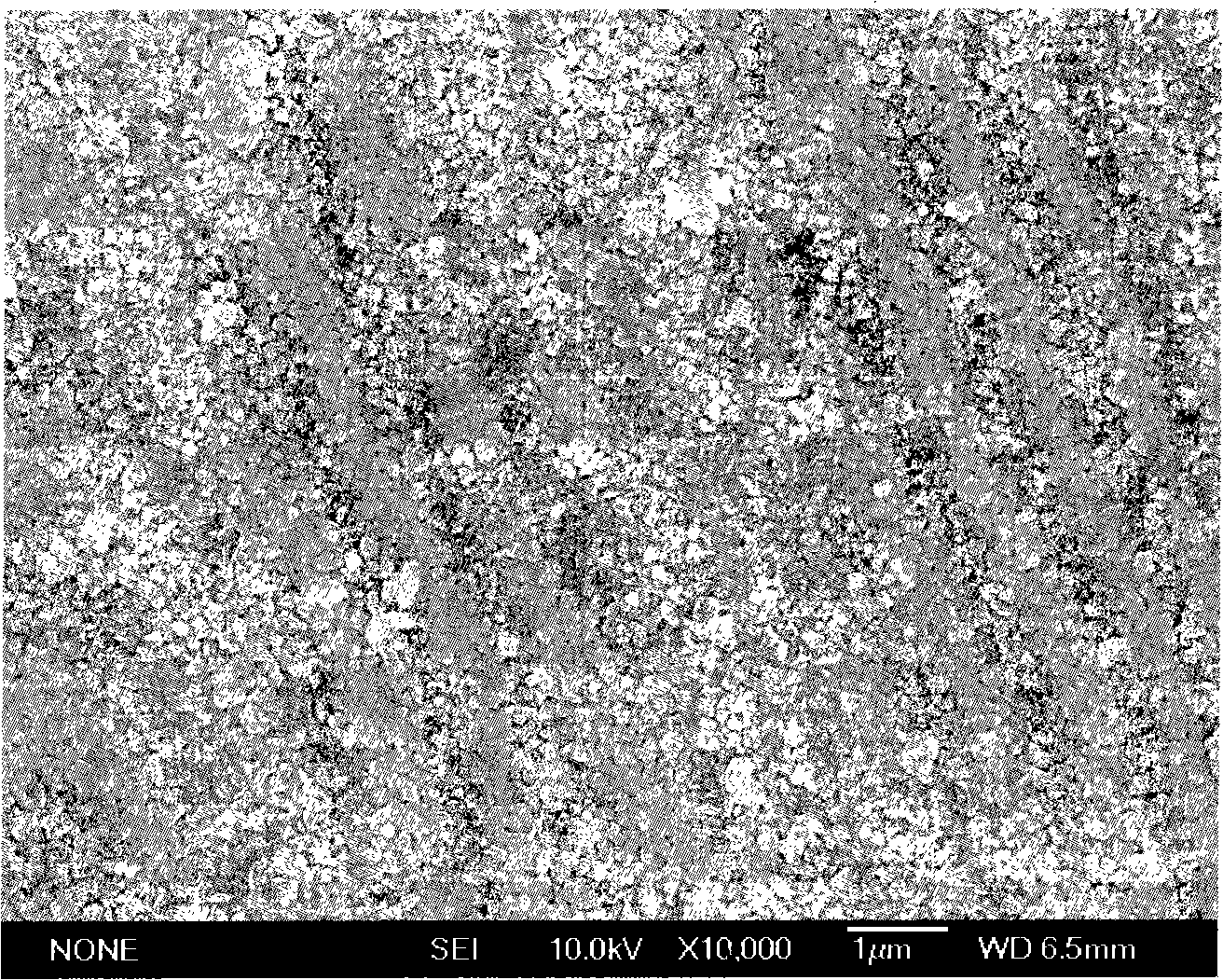

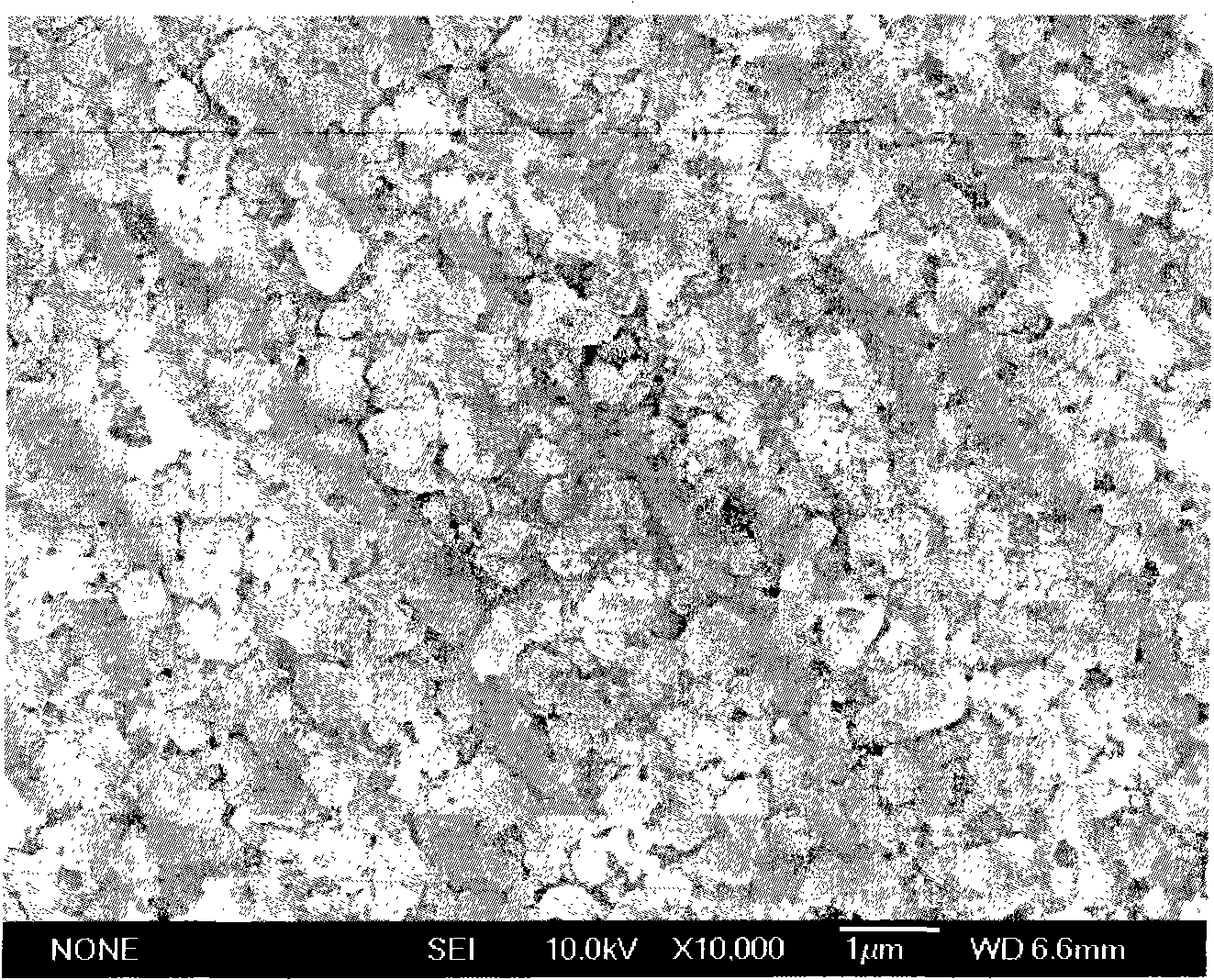

The invention discloses a preparation method for a buffering layer material of a copper indium gallium selenide film solar battery. By the method, a precursor of chemical bath reaction is prepared by using a zinc sulfate solution as a Zn<2+> source, a thiourea solution as a S<2-> source, ammonia water as a buffering agent and sodium citrate as a complexing agent; and a Zn(O,S) semiconductor film with uniform and compact grain size distribution and good adhesive force is prepared on a copper indium gallium selenide film and the common glass substrate and serves as the buffering layer of the copper indium gallium selenide film solar battery. The Zn(O,S) instead of CdS serves as the buffering layer of the copper indium gallium selenide film solar battery, so production of the copper indium gallium selenide film solar battery is environment-friendly and economic. The band gap width of the Zn(O,S) is more than that of the CdS, so more incident photons can reach an absorption layer through the buffering layer, short-circuit current of the battery is increased and photoelectric conversion efficiency of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

METHOD AND APPARATUS FOR DEPOSITING COPPER-INDIUM-GALLIUM SELENIDE (CuInGaSe2-CIGS) THIN FILMS AND OTHER MATERIALS ON A SUBSTRATE

ActiveUS20140273335A1Low costLow production costLiquid surface applicatorsFinal product manufactureSource materialEngineering

An apparatus for deposition of a plurality of elements onto a solar cell substrate comprising: a housing; a transporting apparatus to transport said substrate in and out of said housing; a first tubing apparatus to deliver powders of a first elements to said housing wherein said first tubing apparatus is comprised of a first feeder tube located outside of said housing and joined to said housing; a first source material tube located outside of said housing and joined to said feeder tube; a valves located inside of said first source material tube sufficient to block access between said first source material tube and said first feeder tube; a first heating tube located inside of said housing and connected to said first feeder tube; a second tubing apparatus to deliver powders of a second elements to said housing wherein said second tubing apparatus is comprised of a second feeder tube located outside of said housing and joined to said housing; a second source material tube located outside of said housing and joined to said second feeder tube; valves located inside of said second source material tube sufficient to block access between said second source material tube and said second feeder tube; a second heating tube located inside of said housing and connected to said second feeder tube; a loading station for loading said substrate onto said transporting apparatus; one or more thermal sources to heat said housing and said first heating tube and said second heating tube.

Owner:SOLACTRON

Method for preparing copper indium gallium selenide solar cell optical absorption layer

InactiveCN102569514AMeet the requirementsEasy to manufactureFinal product manufactureSemiconductor devicesIndiumNanoparticles dispersion

The invention relates to the preparation technology of film solar cell, in particular to a preparation method for a copper indium gallium selenide optical absorption layer. The preparation method comprises the steps of (1) uniformly mixing, stirring and ball-milling selenide of metal copper, indium and gallium or metal copper, indium and gallium and selenium simple substance in stoichiometric ratio, and obtaining copper indium gallium selenide nano particles, of which the particle diameter is 10-10,000nm, wherein the atom molar ratio of Cu: In: Ga: Se is (0.9-1):(0-1): (0-1):2; (2) dispersing the copper indium gallium selenide nano particles in a mixing solution formed by dispersant and film-forming agent; stirring or grinding or magnetically stirring and dispersing the particles so as to obtain CIGS (Copper Indium Gallium Selenide) precursor slurry; (3) coating a substrate with the precursor film, drying the precursor film in the air atmosphere to remove the dispersant and the film-forming agent; and obtaining precursor film; and (4) quickly warming and thermally treating the precursor film in the insert atmosphere to obtain copper indium gallium selenide solar cell optical absorption layer film finished product. The method provided by the invention simplifies the process flow, has high production efficiency and is helpful for environment friendliness and; and the method broadens the idea for large-scale industrialization of CIGS film solar cell.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

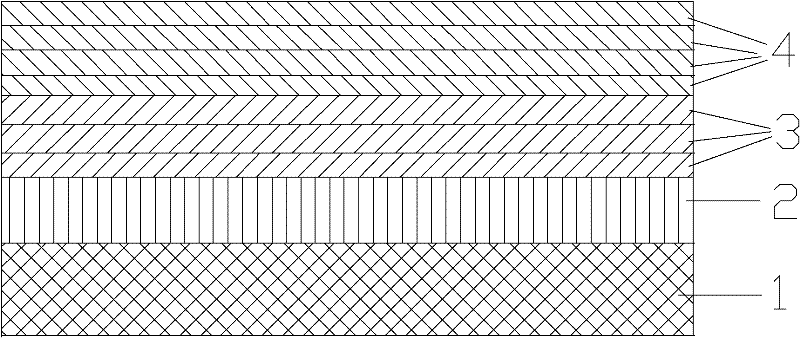

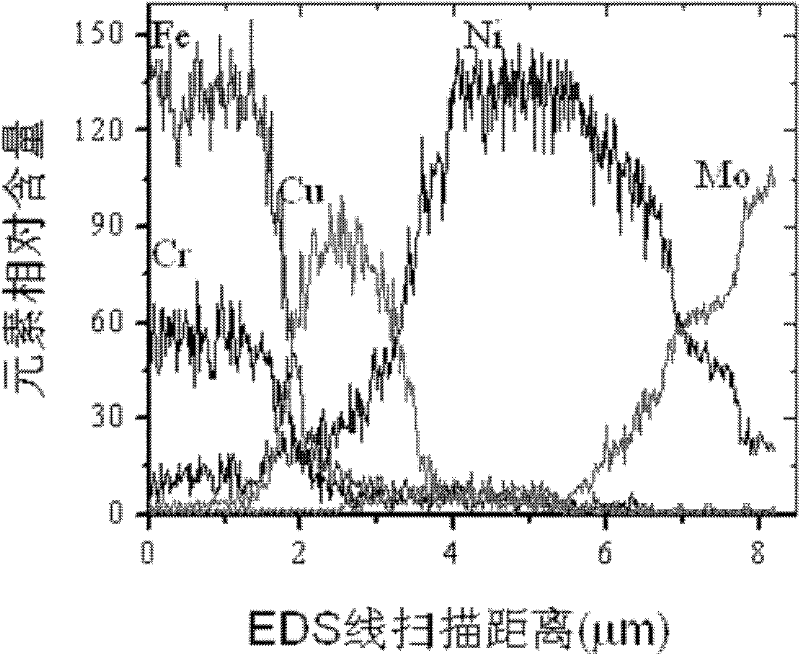

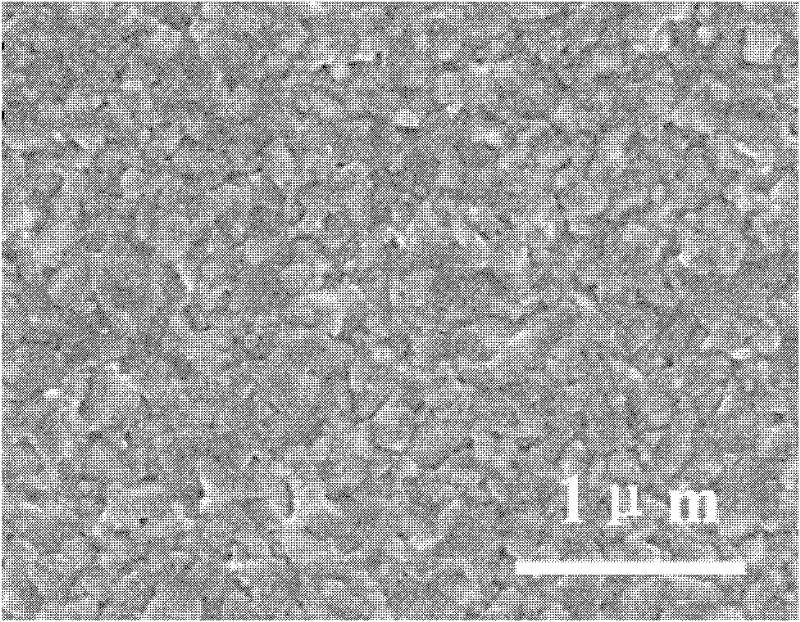

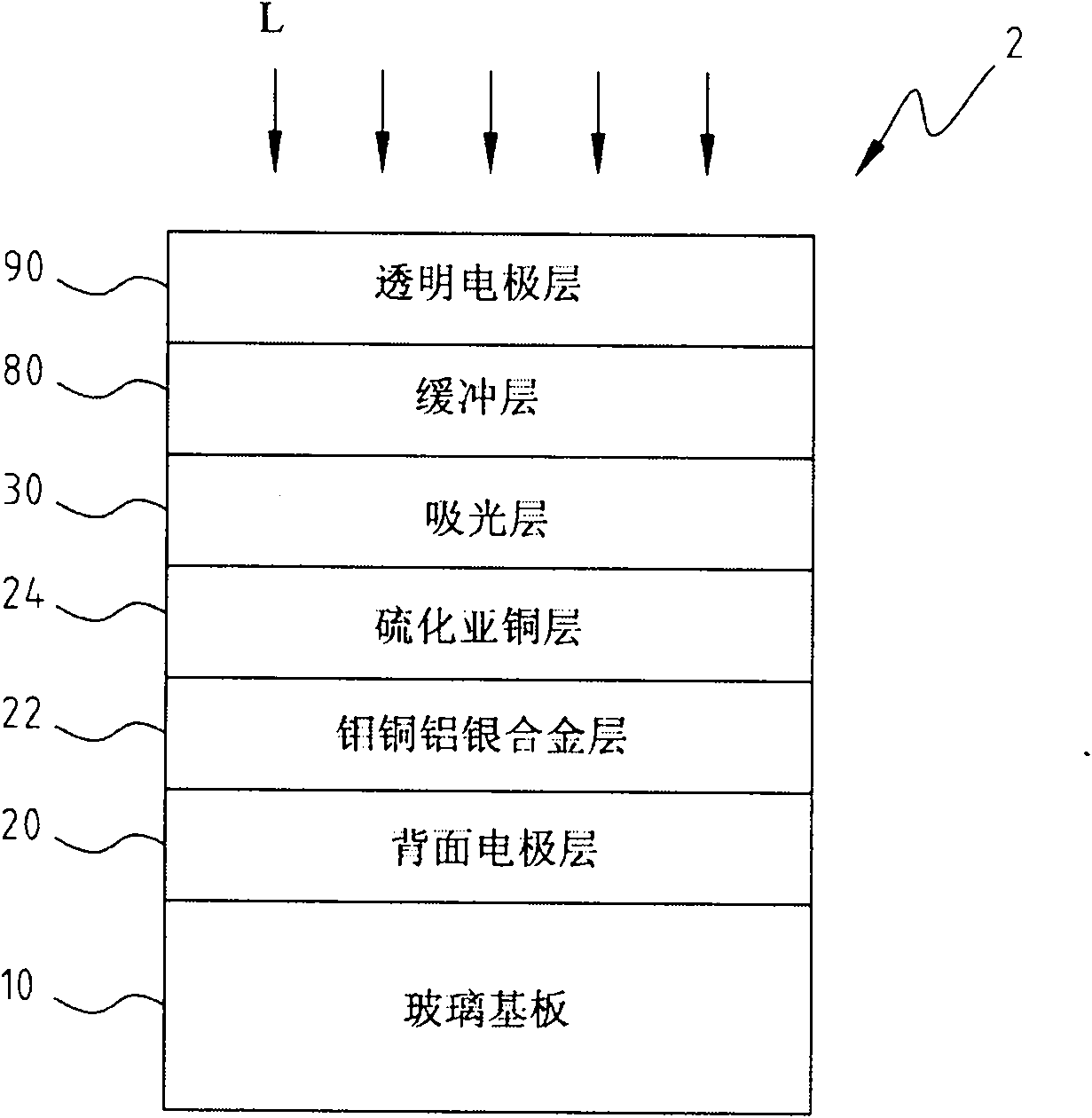

Flexible metal substrate connected with back electrode of solar battery and fabrication method thereof

ActiveCN102201456AImprove production yieldImprove yieldFinal product manufactureSemiconductor devicesContact layerSolar battery

The invention discloses a flexible metal substrate connected with a back electrode of a solar battery and a fabrication method thereof. The flexible metal substrate has a structure made of stainless steel strip / copper / nickel / nickel-molybdenum alloy, wherein a nickel layer and a nickel-molybdenum alloy coating layer serve as diffusion barrier layers which are both multi-layer coating layers; and the mass content of molybdenum in the nickel-molybdenum alloy coating layer in the diffusion barrier layers is gradually increased from 10% to 80% layer by layer along the growth direction of the coating layer. Therefore, the diffusion of copper and Fe element in the steel strip can be effectively prevented, no new harmful elements are introduced, and the nickel-molybdenum alloy with high molybdenum content can enhance the bonding force between the substrate and a back electrode (Mo layer). Meanwhile, a Cu layer serves as a main current conduction layer, so that the Mo layer is only used as theback contact layer capable of forming good ohmic contact with an absorption layer. The flexible metal substrate used as the substrate of a CIGS (copper indium gallium selenide) solar battery can greatly lower the requirement on the thickness of the Mo layer, and the flexible substrate described in the invention can be manufactured continuously with low cost and high efficiency on a continuous electroplating production line.

Owner:HUNAN YONGSHENG NEW MATERIALS

Method for preparing novel conductive indium oxide target and indium oxide film

ActiveCN103205708AImprove compactnessImprove uniformityVacuum evaporation coatingSputtering coatingIndiumElectrical battery

The invention discloses a method for preparing a novel conductive indium oxide target and an indium oxide film. A third element is added to an original binary oxide to improve the electric carrier mobility so as to further improve the light transmittance and the electrical conductivity; and the related target is prepared by the combination of casting molding and high-temperature sintering for the first time. Therefore, the uniformity and compactness of the target are improved; an abnormal electric arc in a sputtering process is greatly reduced; the service life of the target is prolonged; the utilization rate of the target is improved; the quality and the performance of the sputtering film are improved; the efficiency of a copper indium gallium selenide (CIGS) solar cell is effectively improved; and the requirements of production are met.

Owner:赣州市创发光电科技有限公司

Light absorption layer of copper indium gallium selenide (CIGS) solar cell and manufacturing method thereof

InactiveCN102074592AImprove photoelectric conversion efficiencyIncrease absorbanceFinal product manufacturePhotovoltaic energy generationCopper indium gallium selenide solar cellsCuprous sulfide

The invention discloses a light absorption layer of a copper indium gallium selenide (CIGS) solar cell and a manufacturing method thereof. The method comprises the following steps of: forming a cuprous sulfide layer by utilizing a sputtering method; forming a plurality of CIGS stacking layers by utilizing a CIGS sol-gel solution in a soaking, rotating, printing or spraying mode by matching with pre-drying; then fusing the cuprous sulfide layer and the CIGS stacking layers to form a CIGS light absorption layer by utilizing quick heating heat treatment so as to form the CIGS solar cell having high photoelectric conversion efficiency and high light absorbancy.

Owner:JENN FENG NEW ENERY CO LTD

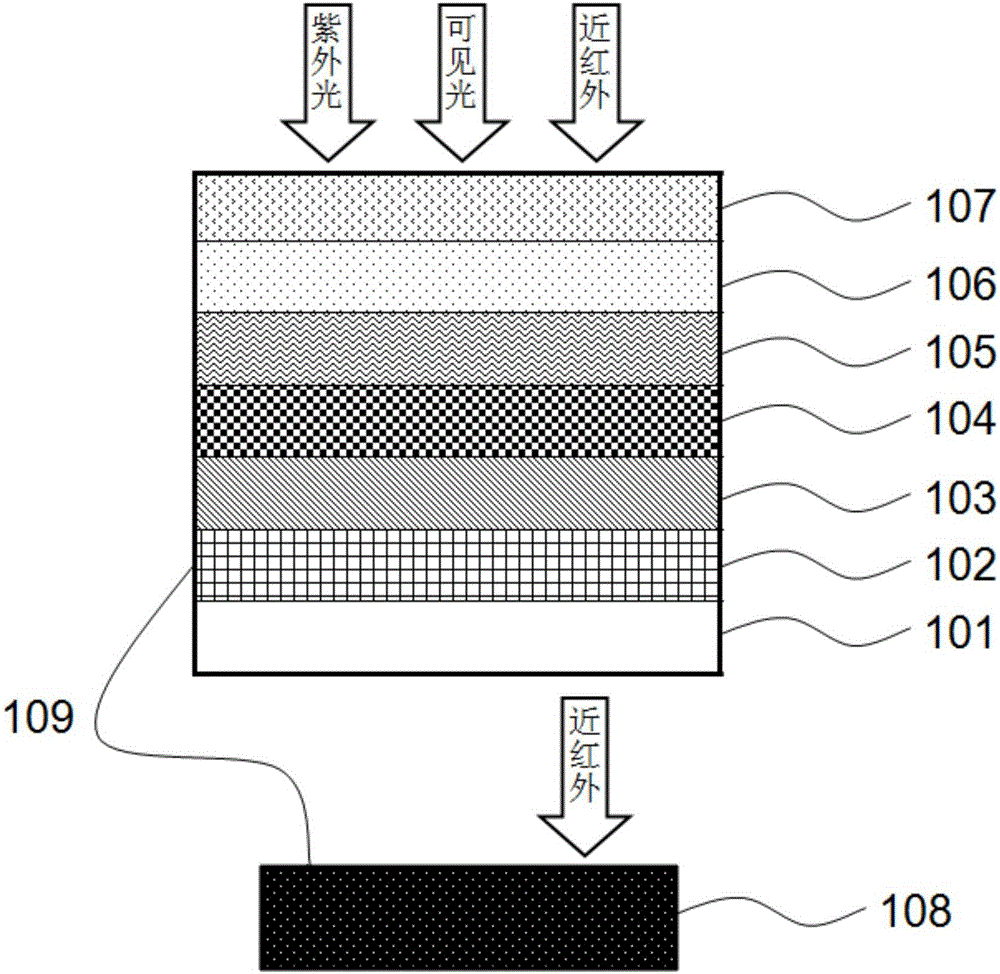

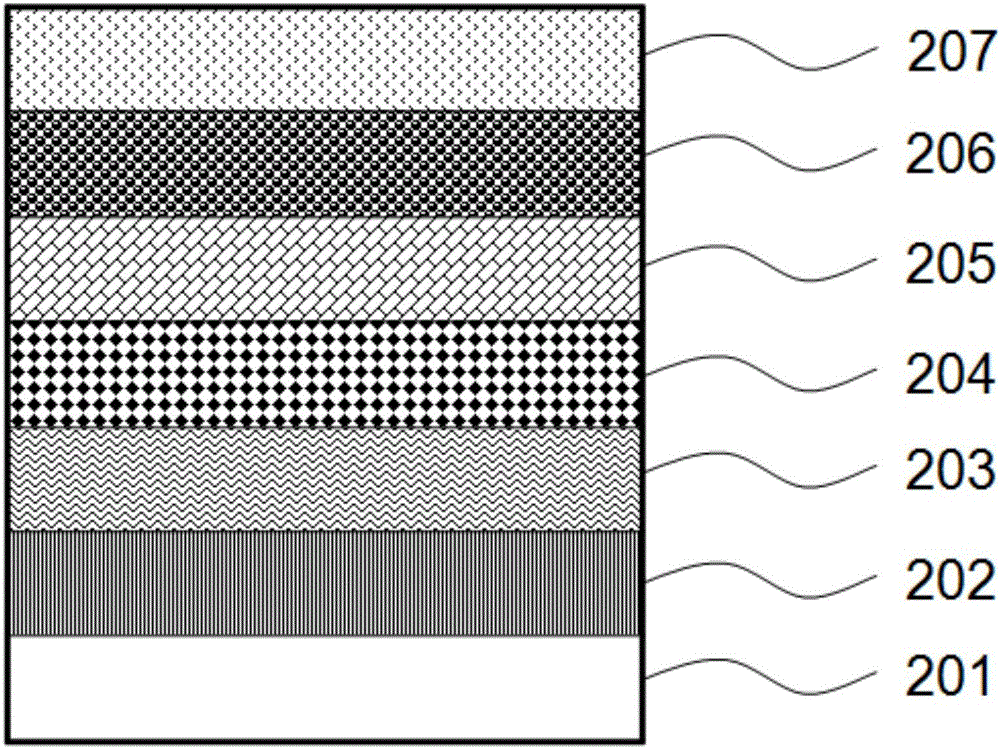

Efficient copper indium gallium selenide/perovskite series solar cell

InactiveCN106129053AImprove energy conversion efficiencyReduce lossesSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionPerovskite solar cell

The invention provides an efficient copper indium gallium selenide / perovskite series solar cell. The four-terminal series solar cell comprises a semitransparent planar heterojunction perovskite solar cell and a copper indium gallium selenide (CIGS) solar cell which are connected in series. The series solar cell can overcome the shortcoming that the perovskite solar call cannot absorb near-infrared light; the efficient copper indium gallium selenide / perovskite series solar cell can effectively absorb ultraviolet light, visible light and near infrared light, so that the solar cell efficiency can be improved; and a new thought for the final commercialization of perovskite is provided.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Method of Making a Multicomponent Film

ActiveUS20120034767A1Consume precursor materialLow costSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingIndiumZinc selenide

Described herein is a method and liquid-based precursor composition for depositing a multicomponent film. In one embodiment, the method and compositions described herein are used to deposit Germanium Tellurium (GeTe), Antimony Tellurium (SbTe), Antimony Germanium (SbGe), Germanium Antimony Tellurium (GST), Indium Antimony Tellurium (IST), Silver Indium Antimony Tellurium (AIST), Cadmium Telluride (CdTe), Cadmium Selenide (CdSe), Zinc Telluride (ZnTe), Zinc Selenide (ZnSe), Copper indium gallium selenide (CIGS) films or other tellurium and selenium based metal compounds for phase change memory and photovoltaic devices.

Owner:VERSUM MATERIALS US LLC

Method for making CIS film based on neutral pH condition double potential step electrodeposit

InactiveCN101262027ASolve poor acid and alkali resistanceSolve corrosiveFinal product manufactureSemiconductor devicesIndiumArgon atmosphere

The invention discloses a method for preparing a copper indium diselenide film by bipotential phase step electrodeposition under neutral pH value, which comprises the steps that: (1) electrodeposition solution is prepared and pH value thereof is 6.5-7.0; (2) a way of bipotential phase step is adopted for plating a film; (3) the film is evaporated in air at room temperature; (4) the film goes through thermal treatment in argon atmosphere at 400 DEG C for 0.5 hour and a CuInSe2 film with copper pyrite structure being obtained. The method adopts the bipotential phase step electrodeposition method for the first time, takes CuCl2question mark 2H2O, InCl3question mark 4H2O and SeO2 as raw materials and CirNa as a complexing agent, which solves the problem of the deposition of the CuInSe2 film on matrixes which have poor acid and alkali resistance and are easily corrosive such as ZnO, etc. The method is an important part of a film solar battery and is used for solar batteries and a plurality of light sensors, etc.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com