Light absorption layer of copper indium gallium selenide (CIGS) solar cell and manufacturing method thereof

A solar cell, copper indium gallium selenide technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of underutilization, affecting the photoelectric conversion efficiency of CIGS solar cells, and the light absorption efficiency cannot be further improved. , to improve the overall absorbance and photoelectric conversion efficiency, high photoelectric conversion efficiency, and enhance the effect of absorbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

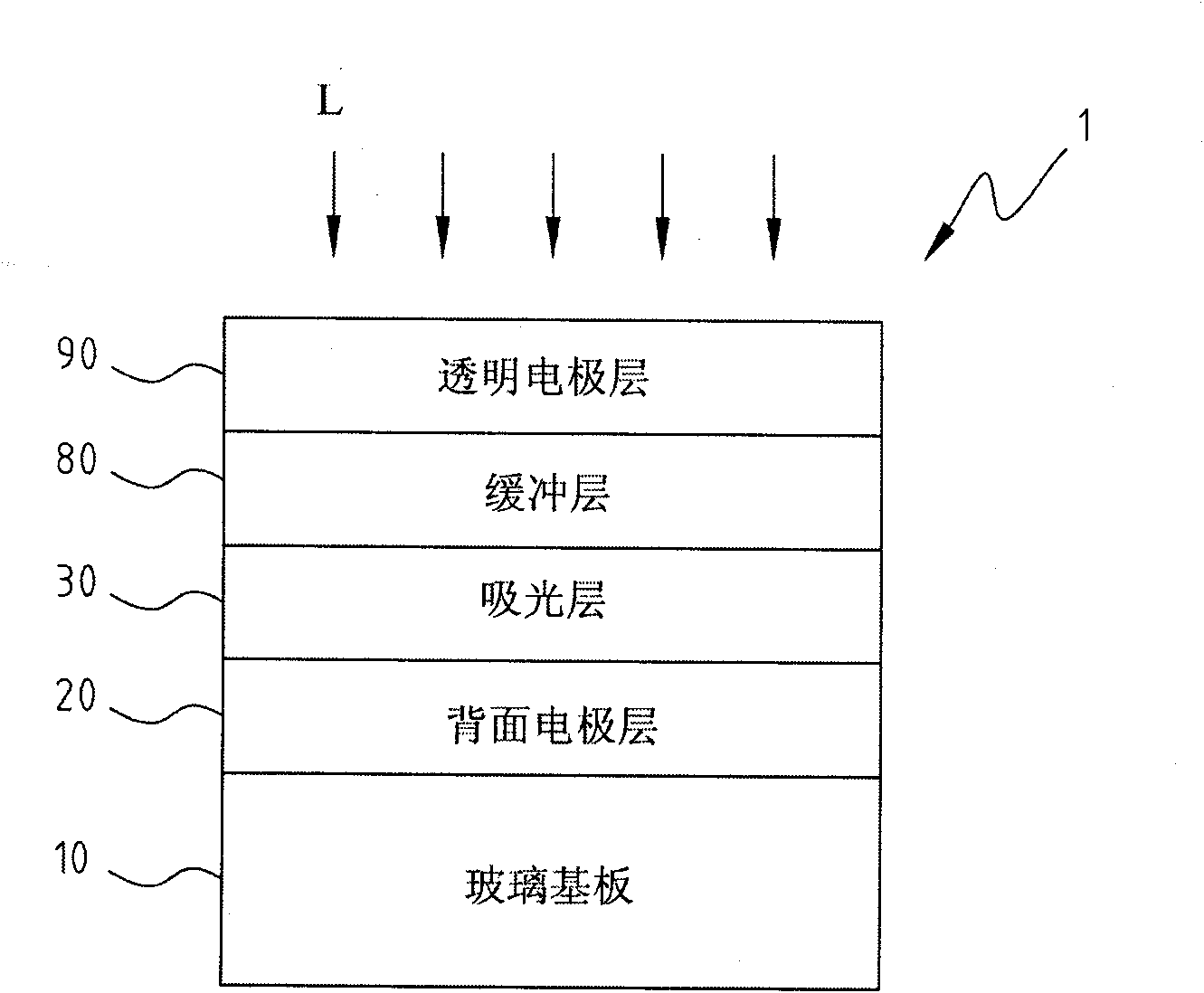

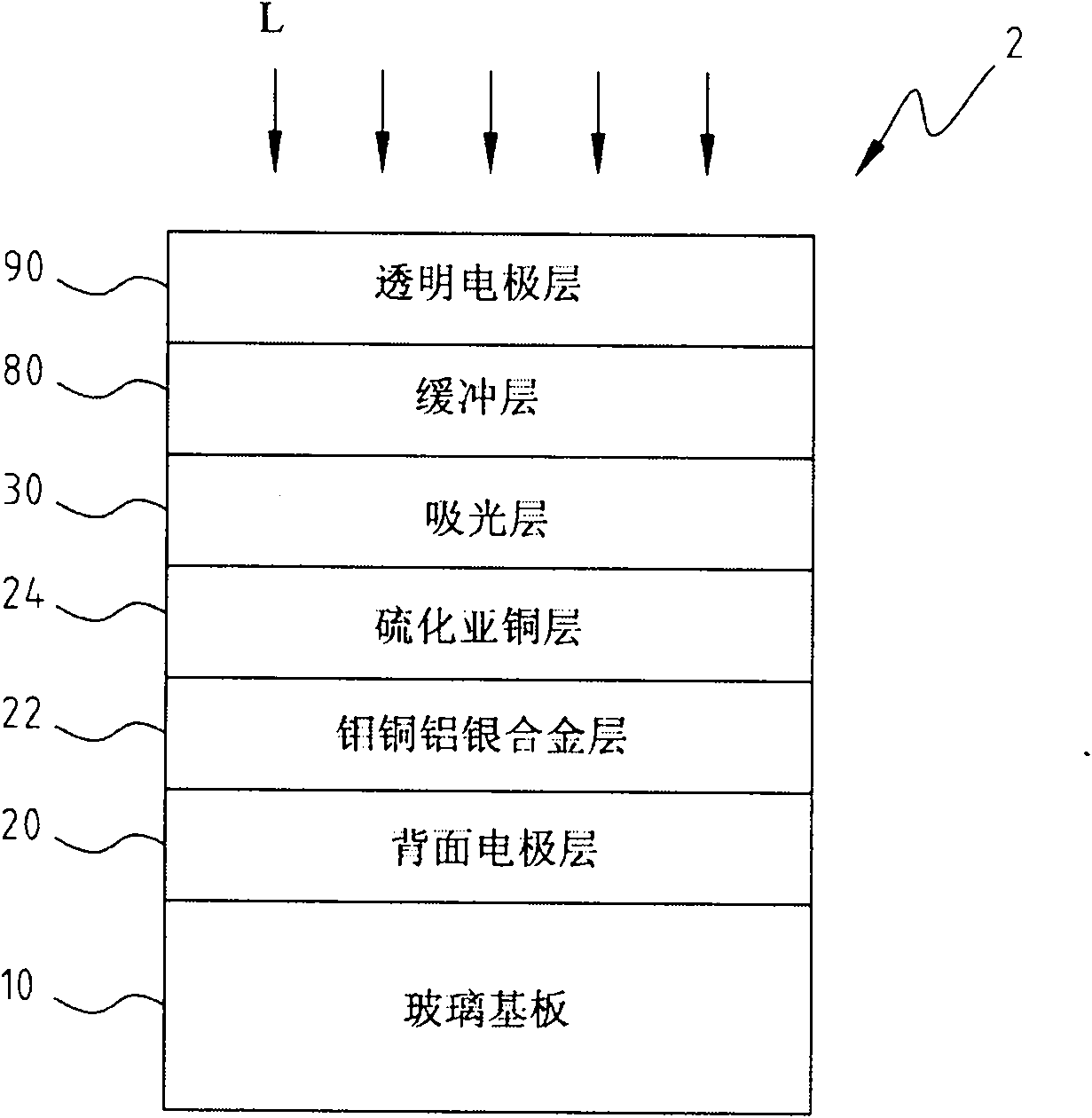

[0028] The following describes the embodiments of the present invention in more detail with the accompanying drawings of the specification, so that those skilled in the art can implement them after studying the specification.

[0029] Refer to Figure 4 , Is a schematic structural diagram of the first embodiment of the present invention. Such as Figure 4 As shown, the CIGS solar cell 3 of the present invention deposits the back electrode layer 20 and the molybdenum-copper-aluminum-silver alloy layer 22 on the glass substrate 10, and then combines the cuprous sulfide layer 24, the first mixed layer 41, and the second mixed layer. The layer 42 and the third mixed layer 43 are sequentially stacked on the molybdenum copper aluminum silver alloy layer 22, and the cuprous sulfide layer 24, the first mixed layer 41, the second mixed layer 42, and the third mixed layer 43 are heat treated to form a high A copper indium gallium sulfide selenide light absorbing layer with light absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com