Method for making CIS film based on neutral pH condition double potential step electrodeposit

An electrodeposition, bipotential technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as limitations and difficulty in finding deposition potentials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

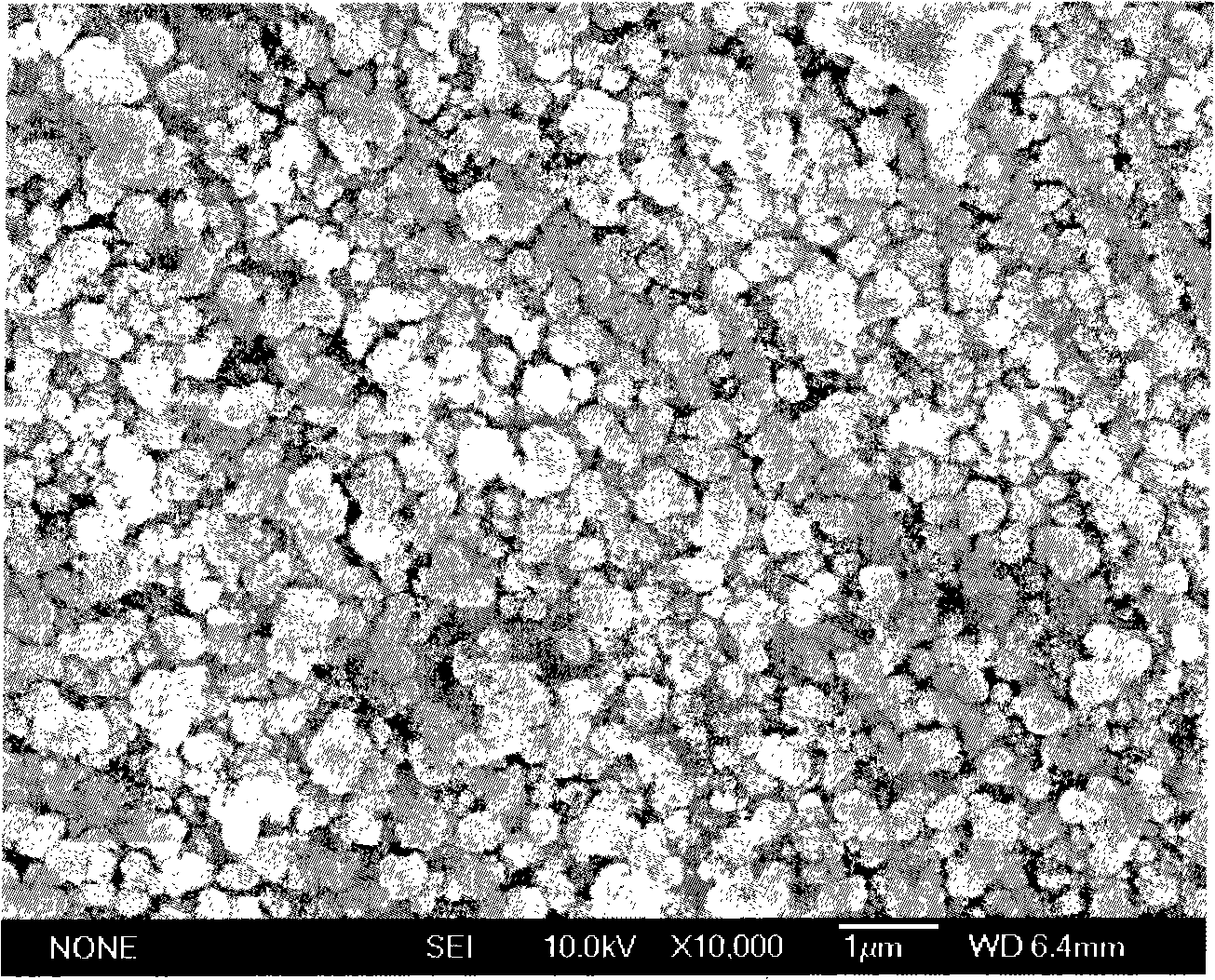

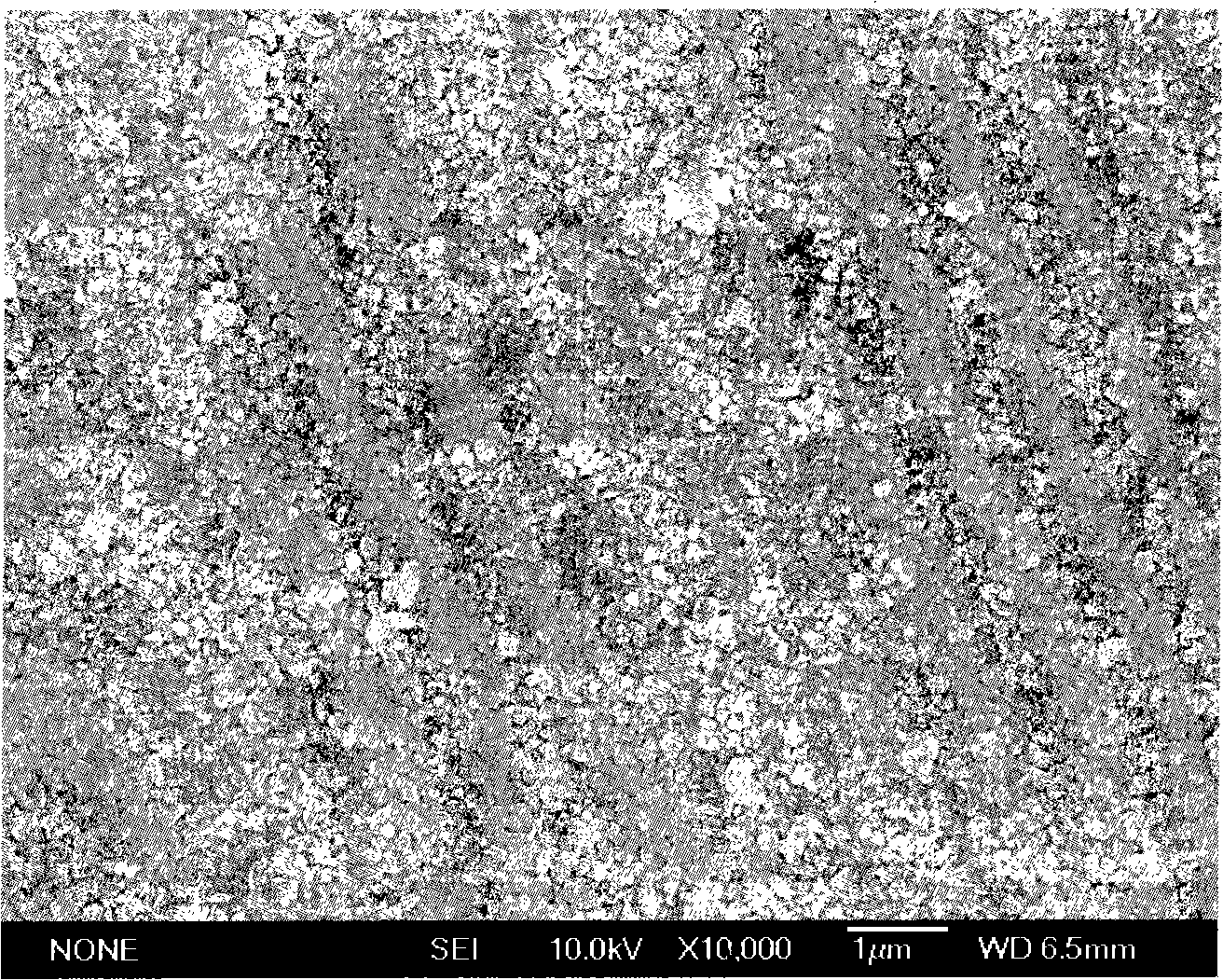

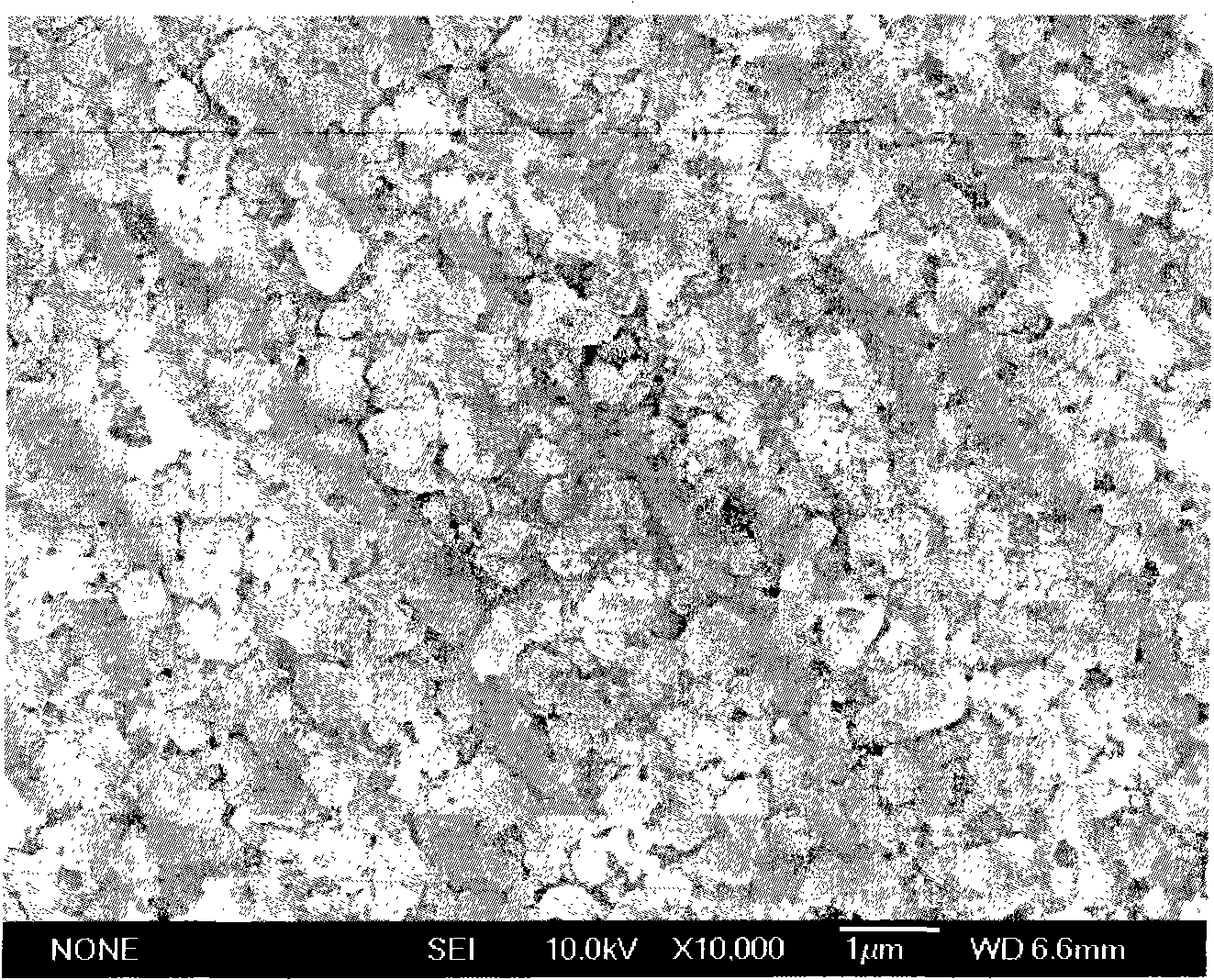

Image

Examples

Embodiment Construction

[0017] The embodiment of the present invention uses chemically pure raw materials. The composition of the electrodeposition solution of the specific embodiment is shown in Table 1, and the parameters of the bipotential step deposition are shown in Table 2.

[0018] Table 1

[0019]

No.

CuCl 2 (mM)

InCl 3 (mM)

SeO 2 (mM)

C 6 h 5 Na 3 o 7- 2H 2 O(mM)

pH

1

2.0

1.0

3.0

15

6.5

2

1.2

0.8

2.0

15

6.5

3

1.0

0.6

1.6

14

7.0

4

1.0

0.6

1.6

14

7.0

5

1.0

2.0

3.0

15

6.5

6

1.0

0.6

1.6

14

7.0

[0020] Table 2

[0021]

No.

Step potential point 1 / continuous

Time (mV / s)

Step potential point 2 / continuous

Time (mV / s)

Cycles

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com