Method for preparing novel conductive indium oxide target and indium oxide film

A technology of conductive oxidation and indium oxide, which is applied in the field of solar photovoltaics, can solve the problems of low light transmittance of transparent conductive films, abnormal arcing of targets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

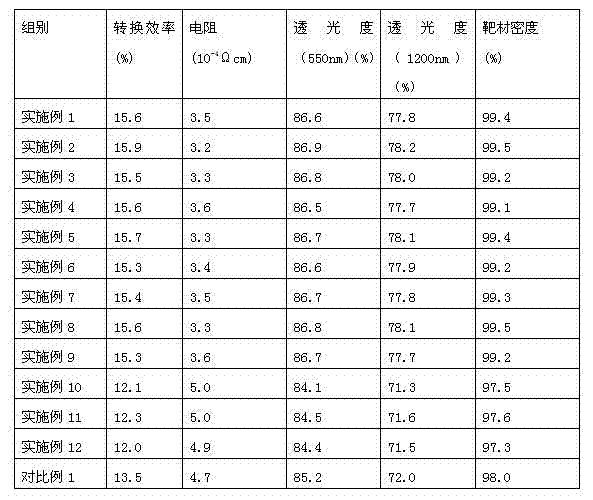

Examples

Embodiment 1

[0015] A method for preparing a new type of conductive indium oxide target material. The weight of the following substances is expressed in parts by weight: add 100 parts of indium oxide to mixed metal oxides, add 68 parts of zirconia balls, 30 parts of pure water and 2 parts Grind and mix the above materials to obtain a slurry, then pour the slurry into a three-inch porous mold, dry for 20 hours, remove the film to form an embryo body, and then sinter at a high temperature of 1400 degrees for 5.5 hours to form a splash The target body for plating is cut and ground into a three-inch conductive indium oxide target.

[0016] The mixed metal oxide is 1 part of tin oxide and 0.1 part of titanium oxide, and the grinding time is 7 hours.

[0017] Wherein the dispersant is an aqueous solution of sodium polyacrylate with a mass fraction of 0.5%.

[0018]A method for preparing a new type of conductive indium oxide film. The above-mentioned conductive indium oxide target material is fi...

Embodiment 2

[0020] A method for preparing a new type of conductive indium oxide target material. The weight of the following substances is expressed in parts by weight: add 100 parts of indium oxide to mixed metal oxides, add 68 parts of zirconia balls, 30 parts of pure water and 2 parts Grinding and mixing the above materials to obtain a slurry, then pouring the slurry into a three-inch porous mold, drying for 24 hours, demoulding to form an embryo body, and then sintering at a high temperature of 1480 degrees for 6.0 hours to form a splash The target body for plating is cut and ground into a three-inch conductive indium oxide target.

[0021] The mixed metal oxide is 5 parts of tin oxide and 1.5 parts of titanium oxide, and the grinding time is 8 hours.

[0022] Wherein the dispersant is an aqueous solution of sodium polyacrylate with a mass fraction of 1.2%.

[0023] A method for preparing a new type of conductive indium oxide film. The above-mentioned conductive indium oxide target m...

Embodiment 3

[0025] A method for preparing a new type of conductive indium oxide target material. The weight of the following substances is expressed in parts by weight: add 100 parts of indium oxide to mixed metal oxides, add 68 parts of zirconia balls, 30 parts of pure water and 2 parts Grinding and mixing the above materials to obtain a slurry, then pouring the slurry into a three-inch porous mold, drying for 28 hours, demoulding to form an embryo body, and then sintering at a high temperature of 1550 degrees for 6.5 hours to form a splash The target body for plating is cut and ground into a three-inch conductive indium oxide target.

[0026] The mixed metal oxide is 10 parts of tin oxide and 3.0 parts of titanium oxide, and the grinding time is 9 hours.

[0027] Wherein the dispersant is an aqueous solution of sodium polyacrylate with a mass fraction of 2%.

[0028] A method for preparing a new type of conductive indium oxide film. The above-mentioned conductive indium oxide target ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com