Fracture liquid and preparation method thereof

A fracturing fluid and base fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of river water pollution, cost increase, water resource shortage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

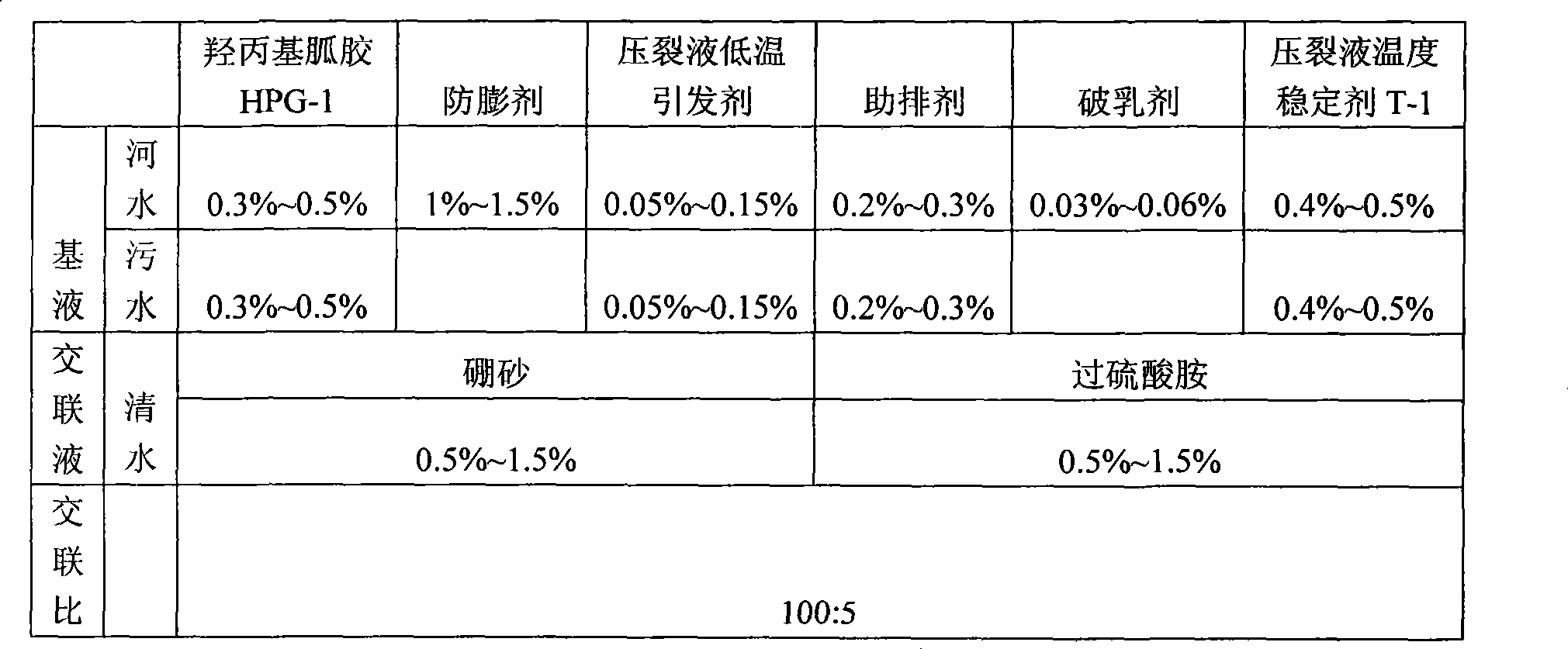

[0024] 2. Preparation method of fracturing fluid:

[0025] When preparing the fracturing fluid of the present invention, the base fluid and the crosslinking fluid should be prepared separately.

[0026] 1. Preparation of base liquid:

[0027] According to the calculated amount, the sewage from the crude oil layer is added to the dosing tank. First, 0.3% to 0.5% of hydroxypropyl guar gum HPG-1 is added to the dosing tank, and then 0.4% to 0.5% is added to the dosing tank. % of fracturing fluid temperature stabilizer T-1, continue to add 0.05% to 0.15% of fracturing fluid low-temperature initiator in the liquid mixing pool, and finally add 0.2% to 0.3% of drainage aid in the liquid mixing pool, and then Stir the dosing pool for 100 to 120 minutes to complete the configuration of the required base liquid.

[0028] 2. Preparation of cross-linking solution:

[0029] Add clean water to the dosing tank according to the calculated amount, first add 0.5% to 1.5% ammonium persulfate ...

Embodiment 1

[0044] Get 0.3% hydroxypropyl guar gum HPG-1, 0.4% fracturing fluid temperature stabilizer T-1, 0.05% fracturing fluid low-temperature initiator, 0.2% drainage aid and remaining The amount of sewage from the crude oil layer is added to the dosing tank, first add 0.3% hydroxypropyl guar gum HPG-1 to the dosing tank, and then add 0.4% to the dosing tank fracturing fluid temperature stabilizer T-1, continue to add 0.05% fracturing fluid low-temperature initiator in the liquid mixing tank, and finally add 0.2% drainage aid in the liquid mixing tank, and then stir the mixing tank for 100 minutes, That is, the configuration of the base liquid is completed;

[0045] Take 0.5% ammonium persulfate, 0.5% borax and the clear water of the balance respectively according to the total amount of 100%, add the clear water in the liquid mixing tank, first add 0.5% ammonium persulfate in the liquid mixing tank, and then add Add 0.5% borax to the dosing tank, and finally stir the dosing tank for...

Embodiment 2

[0048] Get 0.5% hydroxypropyl guar gum HPG-1, 0.5% fracturing fluid temperature stabilizer T-1, 0.15% fracturing fluid low-temperature initiator, 0.3% drainage aid and remaining Measure the sewage from the crude oil layer, add the sewage from the source and the crude oil layer to the dosing tank, first add 0.5% hydroxypropyl guar gum HPG-1 to the dosing tank, and then add 0.5% to the dosing tank fracturing fluid temperature stabilizer T-1, continue to add 0.15% fracturing fluid low-temperature initiator in the liquid mixing tank, and finally add 0.3% drainage aid in the liquid mixing tank, and then stir the mixing tank for 120 minutes, That is, the configuration of the base liquid is completed;

[0049] Take 1.5% ammonium persulfate, 1.5% borax and the clear water of the balance respectively according to the total amount of 100%, add the clear water in the liquid mixing tank, first add 1.5% ammonium persulfate in the liquid mixing tank, and then Add 1.5% borax to the dosing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com